Vegetable sorting device for cold-chain logistics

A sorting device and cold chain logistics technology, applied in grading, solid separation, cleaning of hollow objects, etc., can solve the problems of wasting manpower, slow manual sorting, and increasing labor costs, and achieve high sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

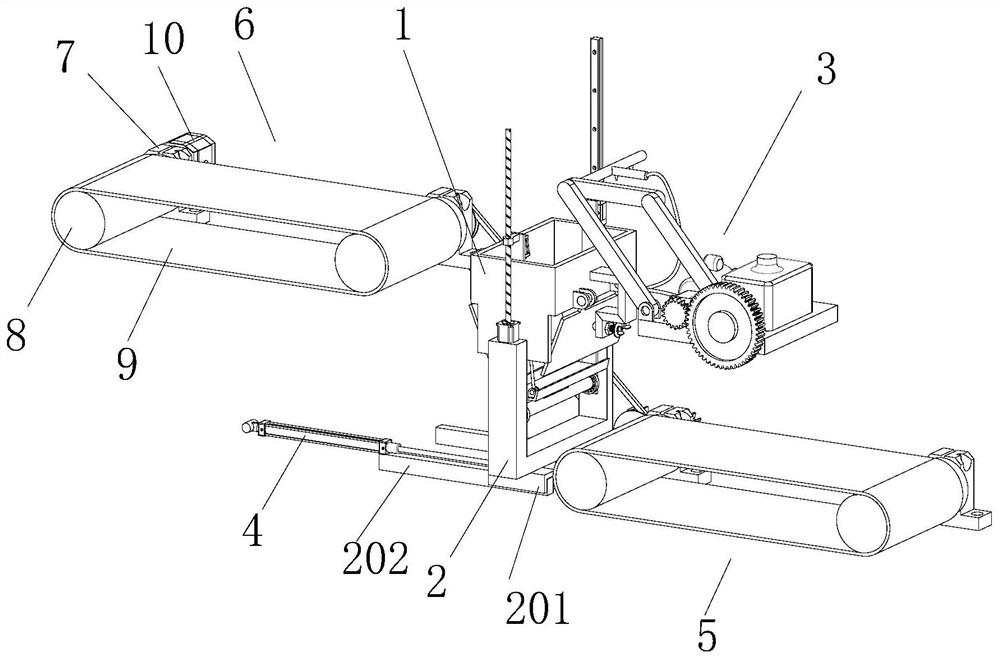

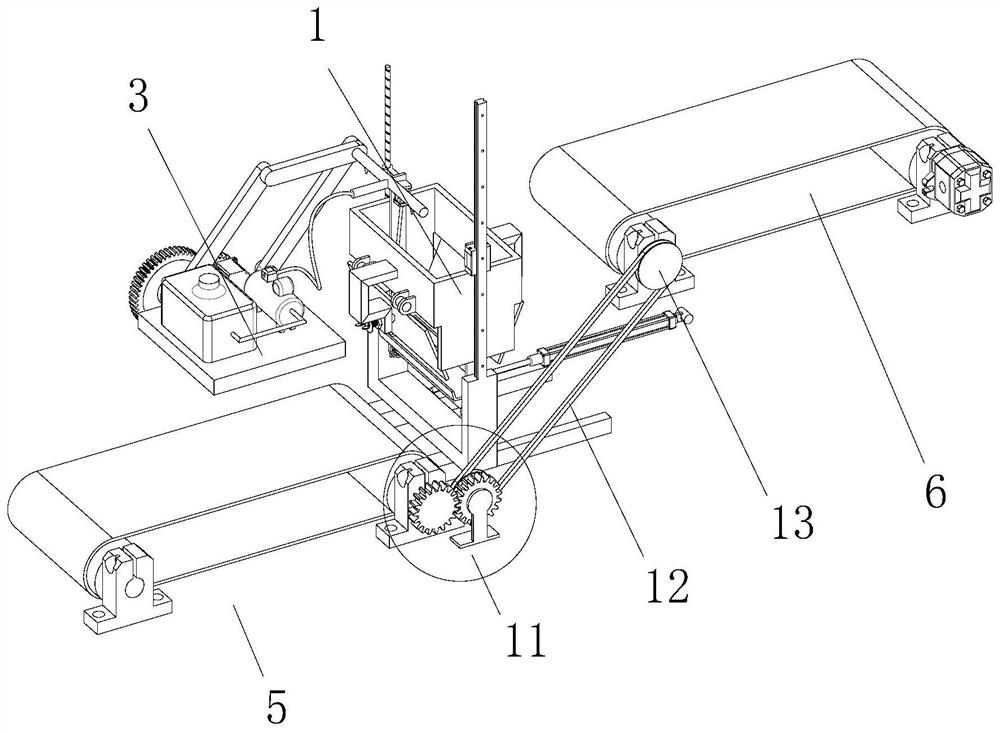

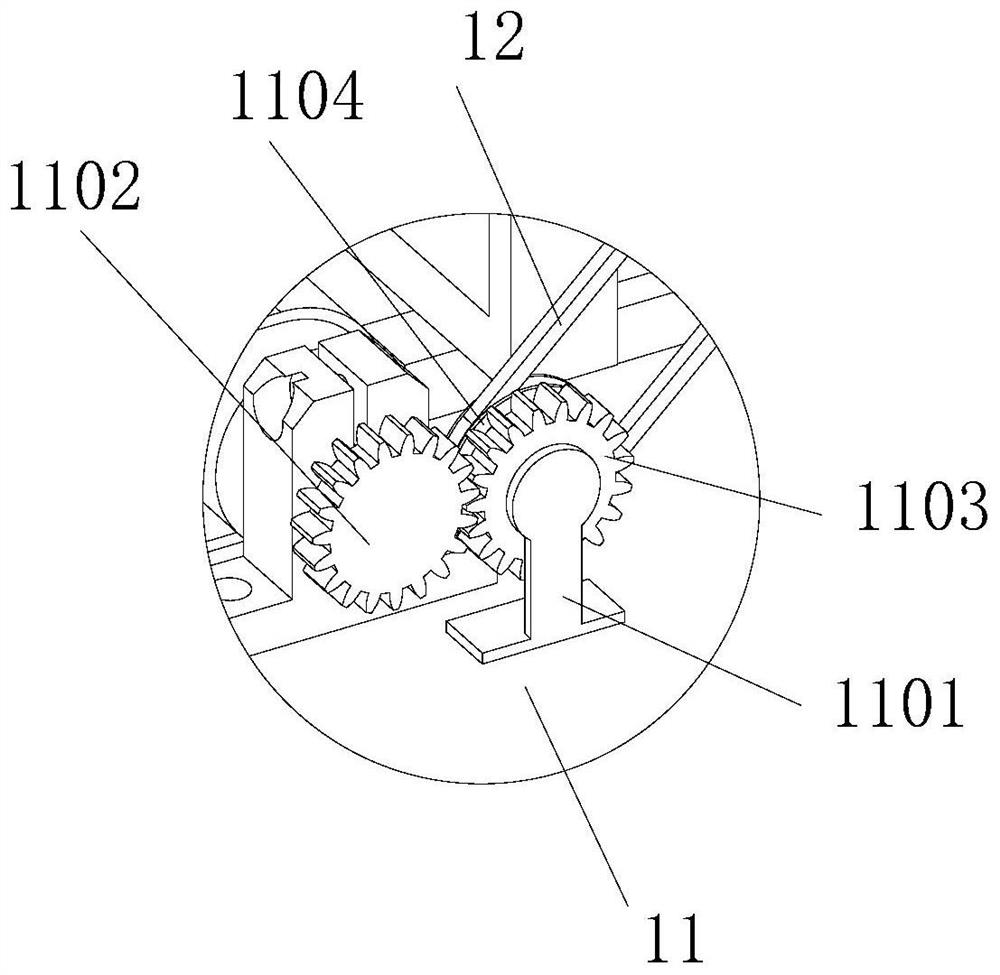

[0028] refer to Figure 1 to Figure 9 The shown vegetable sorting device for cold chain logistics includes a material distribution box 1, the material distribution box 1 is fixedly installed, and both sides of the material distribution box 1 are provided with opening and closing plates 18, and each opening and closing plate 18 Fixed hinged block 19 is installed on the distribution box 1 of top, and the top of opening and closing plate 18 is provided with the round bar that matches with fixed hinged block 19, and the both sides of material distribution box 1 is all provided with support frame 101, and the support frame 101 The bottom end is provided with a screw rod 20, the bottom end of the support frame 101 is provided with a fixed nut 2003 matching the screw rod 20, the screw rod 20 is inserted inside the fixed nut 2003, and a wrench 2001 is installed at one end of the screw rod 20, The other end of the screw rod 20 is provided with a ball head 2002, the ball head 2002 fits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com