A hot air structure for cooking equipment and an oven with the structure

A cooking equipment and hot air technology, applied in kitchen utensils, home utensils, applications, etc., can solve the problems of the service life of the hot air blower, increase the working noise of the whole machine, and affect the user experience, so as to promote hot air circulation and speed up heating speed, enhanced cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

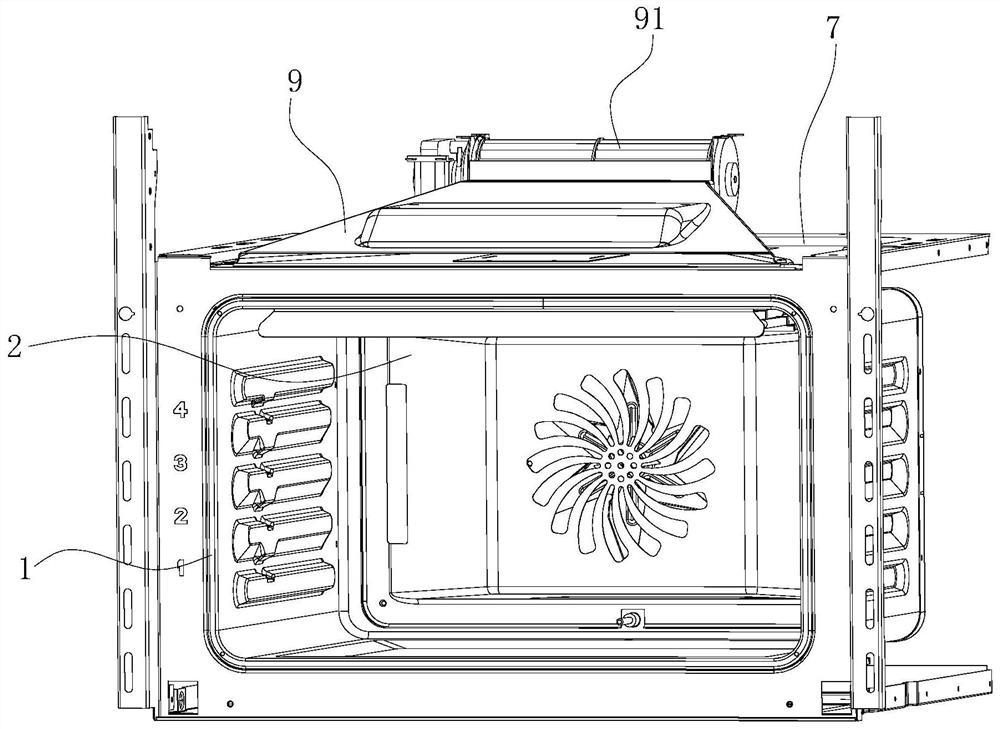

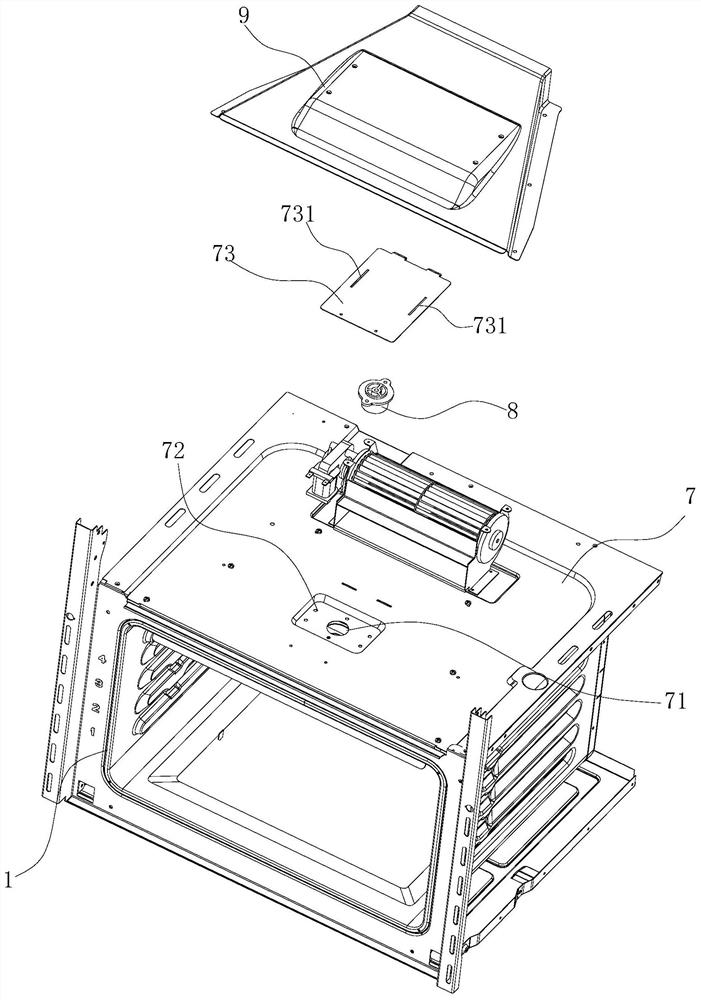

[0032] like Figures 1 to 14 As shown, an oven includes an exhaust structure, and the exhaust structure includes an inner tank 1 and a hot air blower 4 . Above the inner pot 1 is provided an upper mounting plate 7, and the upper surface of the upper mounting plate 7 is covered with an air guide hood 9 to form an exhaust passage 90 with an exhaust fan 91. On the top wall of the inner pot 1 An exhaust port 11 is provided, and the upper mounting plate 7 is provided with an air inlet 71 with the exhaust passage 90 , and the lower end of the ventilation plug 8 with a vertically extending ventilation hole 81 in the center is inserted into the exhaust port 11 The middle and upper ends are inserted into the above-mentioned air inlet 71, and the upper end of the above-mentioned ventilation plug 8 is concave downward along the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com