Hot air structure for cooking equipment and oven with hot air structure

A technology of cooking equipment and hot air, which is applied in kitchen utensils, household utensils, applications, etc., can solve the problems of affecting the service life of the hot air blower, affecting the user experience, and increasing the working noise of the whole machine, so as to increase the effective air intake and improve Cooking effect, the effect of accelerating the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

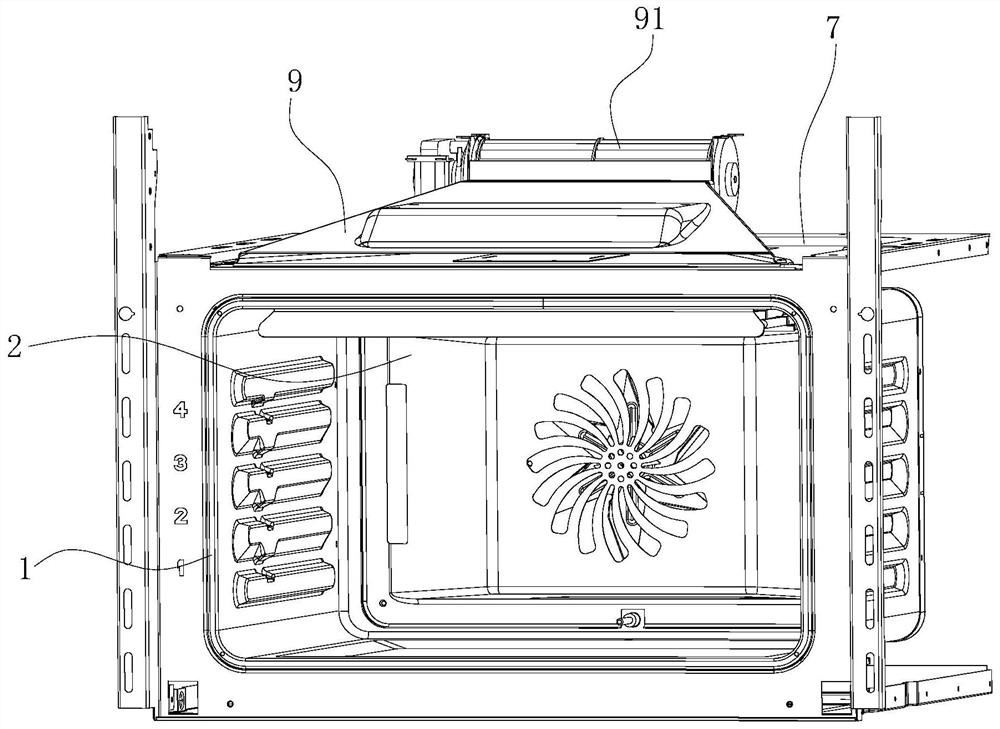

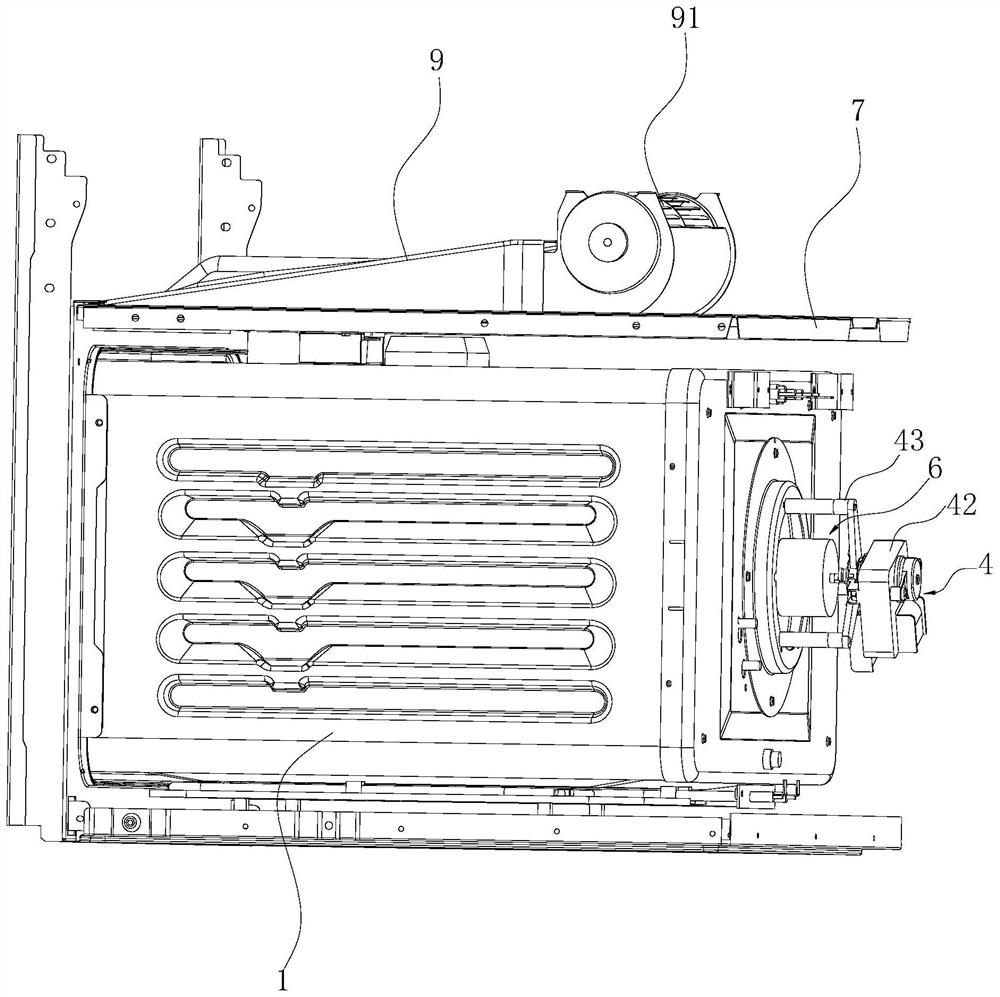

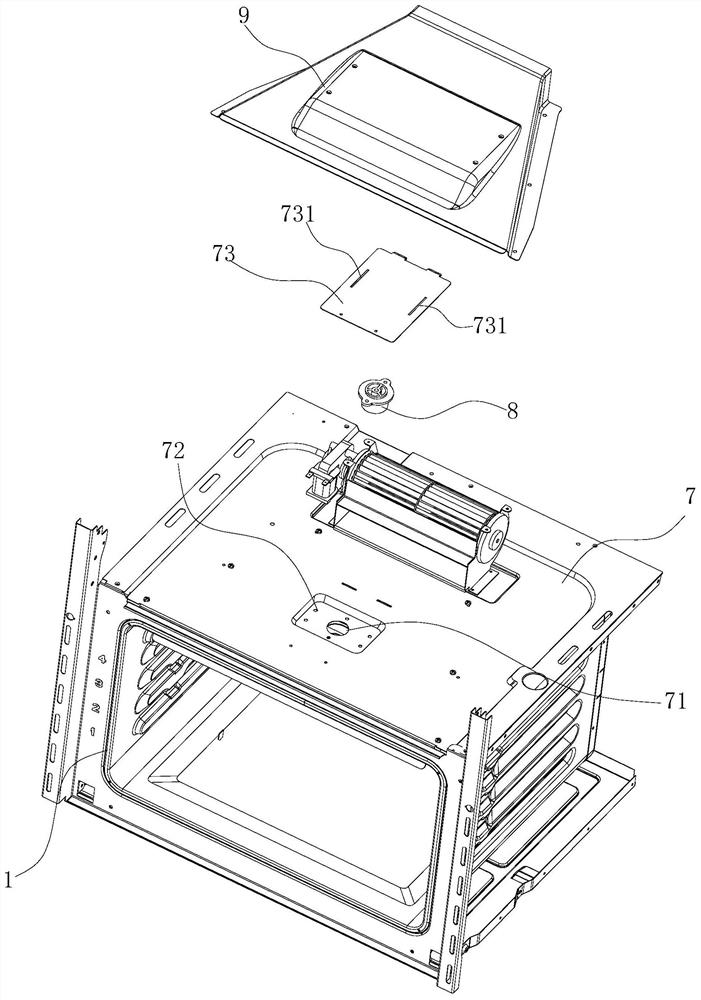

[0032] Such as Figure 1-14 As shown, an oven includes an exhaust structure, and the exhaust structure includes an inner container 1 and a hot air blower 4 . Above the above-mentioned liner 1 is provided with an upper mounting plate 7, the upper surface of the upper mounting plate 7 is covered with a wind guide cover 9 to form an exhaust passage 90 with an exhaust fan 91, and on the top wall of the above-mentioned liner 1 An air outlet 11 is provided, and the upper mounting plate 7 is provided with an air inlet 71 having the above-mentioned exhaust channel 90, and the lower end of the ventilation plug 8 with a vertically extending air hole 81 in the center is inserted into the above-mentioned air outlet 11. The middle and upper end are inserted in the above-mentioned air inlet 71, and the upper end of the above-mentioned ventilation plug 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com