Conveying mechanism moving along with soil sampling mechanism

A conveying mechanism and displacement technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems that the conveying device cannot be used in conjunction with the bolt and drill pipe, and the soil conveying efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

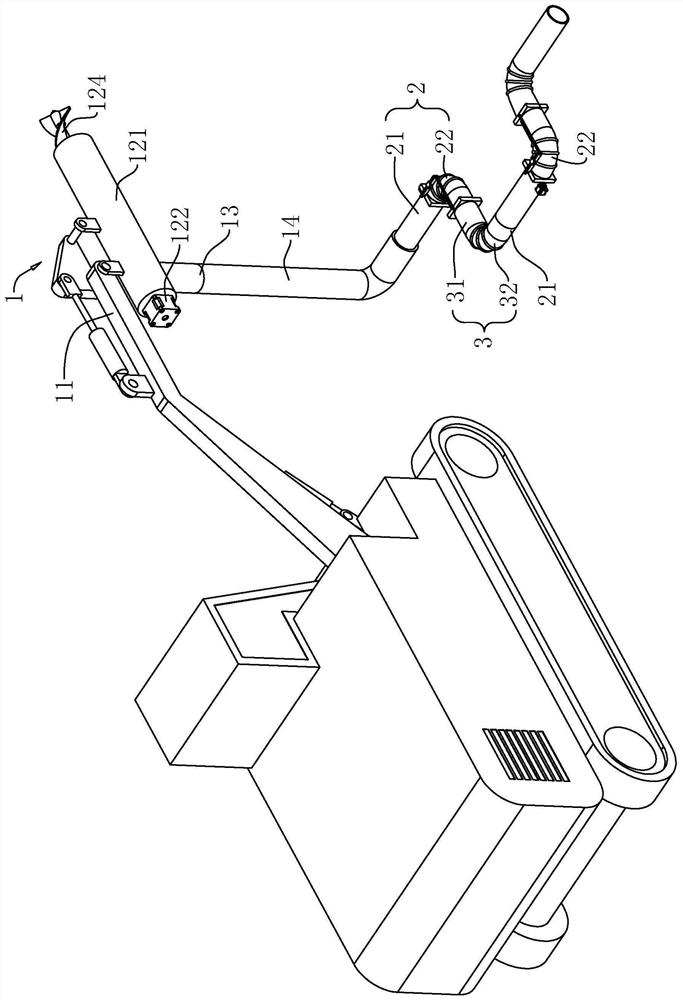

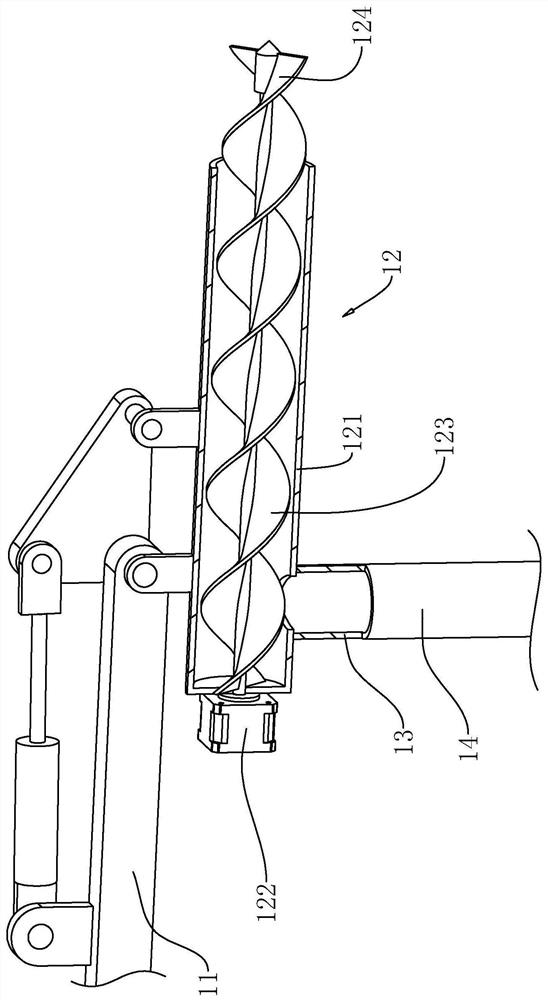

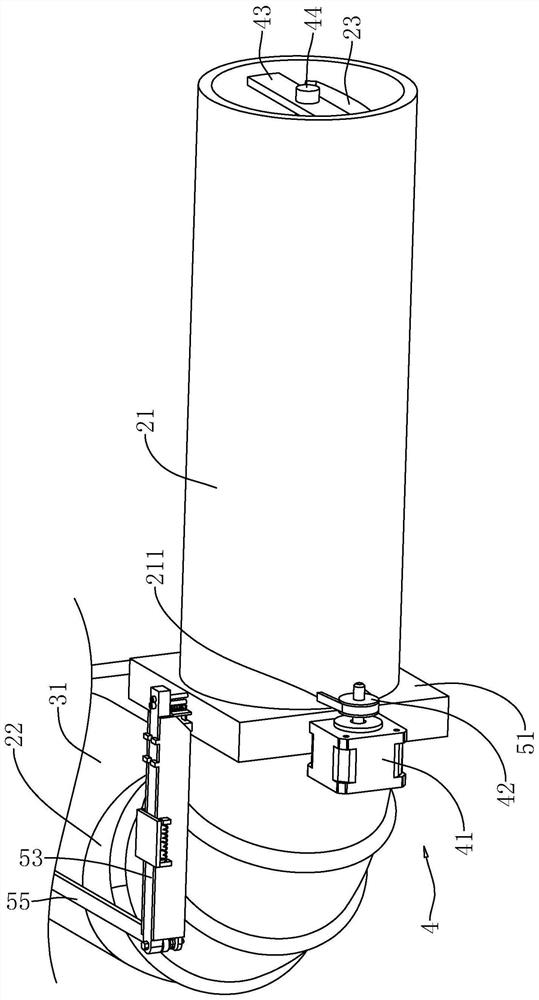

[0037] The following is attached Figure 1-8 The application is described in further detail.

[0038] The embodiment of the present application discloses a conveying mechanism that is displaced with the earth-taking mechanism. refer to Figure 1-2 , the conveying mechanism with the displacement of the earth-taking mechanism is used in conjunction with the earth-boring equipment 1 . The earth drilling equipment 1 comprises a body 11, an earth taker 12 installed on the body 11, and the earth taker 12 includes a steel sleeve 121 installed on the body 11, a power head 122 installed at the tail of the steel sleeve 121, a power head 122 installed on the steel sleeve Inside 121, the auger rod 123 driven by the power head 122 and the excavation bit 124 installed on the end of the auger rod 123 away from the power head 122, the excavation bit 124 stretches into the inside of the earthwork to be excavated, and excavates the earthwork. The bottom of the steel sleeve 121 is communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com