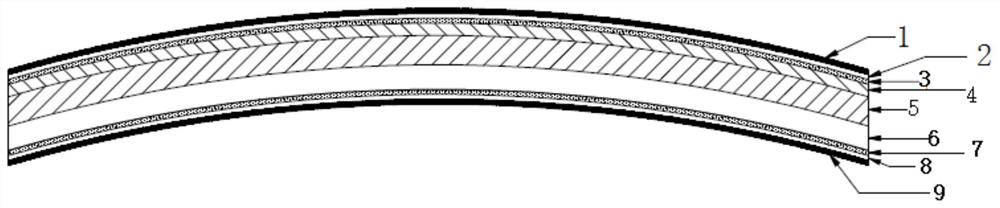

An ophthalmic lens comprising a photochromic coating cured by visible light

A technology for visible light and spectacle lenses, applied in the field of spectacle lenses, to achieve the effects of reducing equipment and site investment, improving production pass rate, and shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

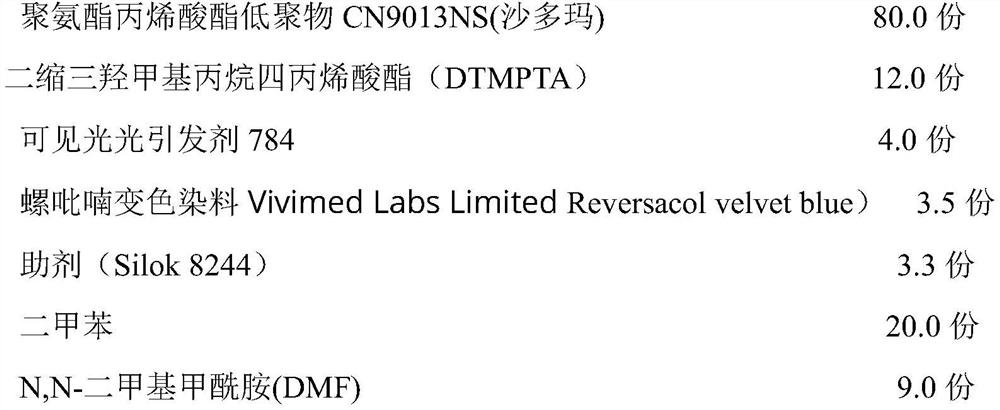

Embodiment 1

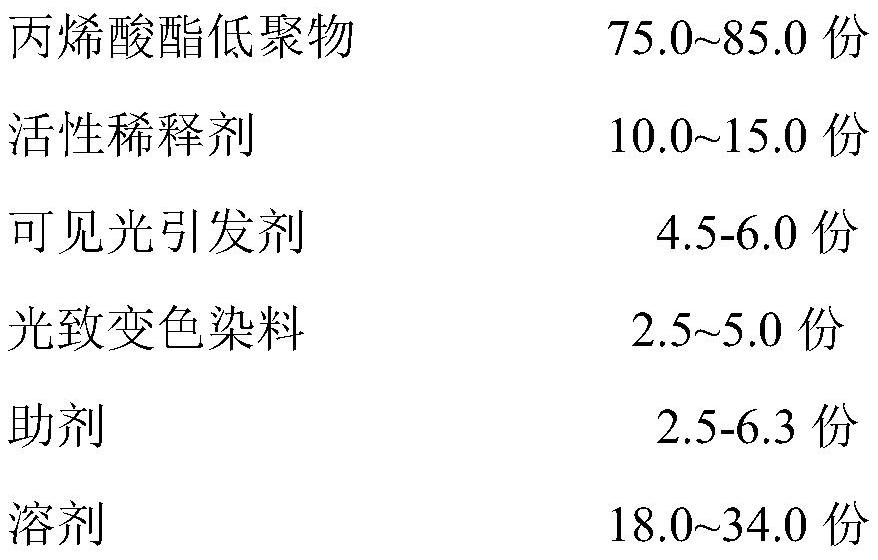

[0021] The materials and formulations of the photochromic coating are as follows:

[0022]

[0023] Accurately weigh CN9013NS, DTMPTA, Silok 8244, DMF and 50% xylene in the formula, add it into the batching tank at room temperature, stir until all materials are completely mixed evenly, and continue stirring for 1 hour. Take another small pot, add the weighed color-changing dye Reversacol velvet blue, visible light photoinitiator 784, and then add the remaining 50% of the formula amount of xylene, stir at room temperature for 0.5 hours, and observe whether the materials are completely dissolved. After the dissolution is complete, all the solution in the small tank is added into the batching tank, and stirred for 0.5 hours to make it evenly mixed. Filter the mixed solution with filter paper with 5 micron filter holes, and take a sample for testing. The viscosity of the mixed solution is 82.3cps@25°C.

[0024] After the preparation of the above mixed solution is completed, it...

Embodiment 2

[0027] The materials and formulations of the photochromic coating are as follows:

[0028]

[0029] The mixed solution was prepared by a process similar to that of Example 1, and a sample was taken for testing. The viscosity of the mixed solution was 98.7cps@25°C.

[0030] The ophthalmic lens containing the photochromic coating cured by visible light was prepared by a process similar to that of Example 1.

[0031] The obtained spectacle lens has a reversible photochromic function, and the color becomes darker under sunlight and can fade indoors. The resulting spectacle lens was irradiated with an ultraviolet lamp for 3 minutes, and immediately tested with a Japan Shimadzu U-2600 spectrophotometer, the visible light transmittance of the spectacle lens was 21.7%, and the visible light transmittance of the spectacle lens after 10 minutes was 86.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com