Heavy-duty car axle housing shaping and measuring device for stamping and welding

A technology of measuring device and heavy-duty vehicle, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of high labor intensity, difficult processing, time-consuming and labor-intensive, etc., to avoid debris, good use value, and economical The effect of a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

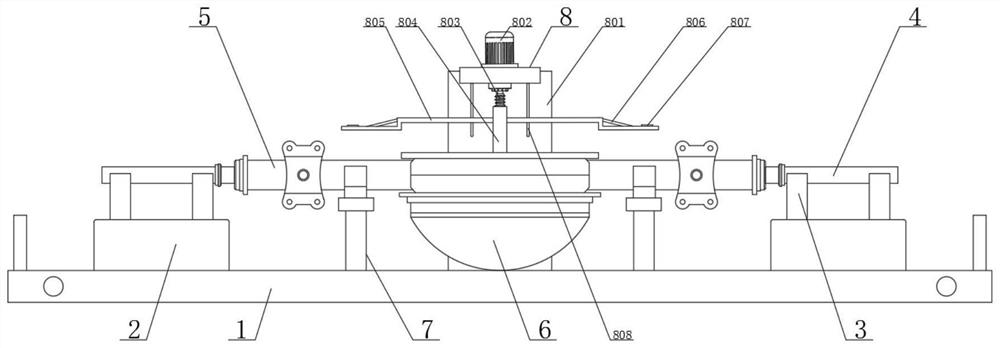

[0024] see figure 1 , figure 1 , image 3 with Figure 4 , the present invention provides a technical solution:

[0025]A heavy-duty automobile axle housing shaping and measuring device for stamping and welding, including a workbench 1 and a fixed block 2, a measuring device 8 is slidingly connected to the rear of the upper end surface of the workbench 1, and the measuring device 8 includes a sliding frame 801 and a rotating motor 802. The lower end surface of the frame 801 is slidingly connected with the workbench 1, the upper end surface of the sliding frame 801 is fixedly connected with a rotating motor 802, the end of the main shaft of the rotating motor 802 is fixedly connected with a moving threaded rod 803, and the outer side of the moving threaded rod 803 is spirally connected with a threaded sleeve 804. The lower end surface of 804 is fixedly connected with a cleaning device 9, the left and right sides of the threaded sleeve 804 are fixedly connected with a measuri...

Embodiment 2

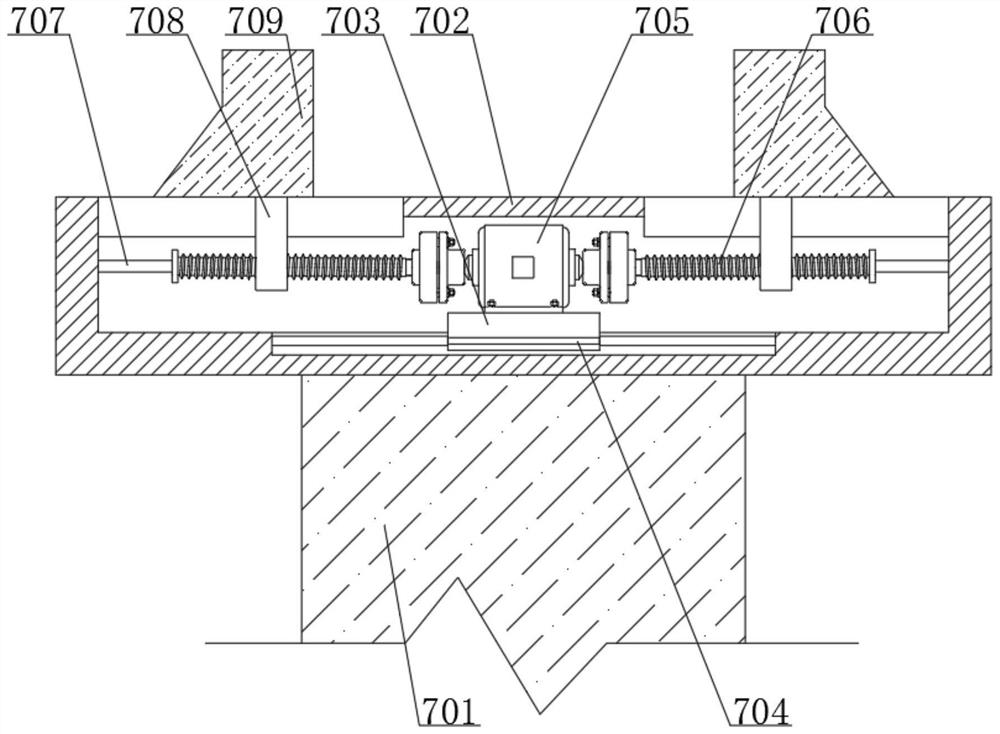

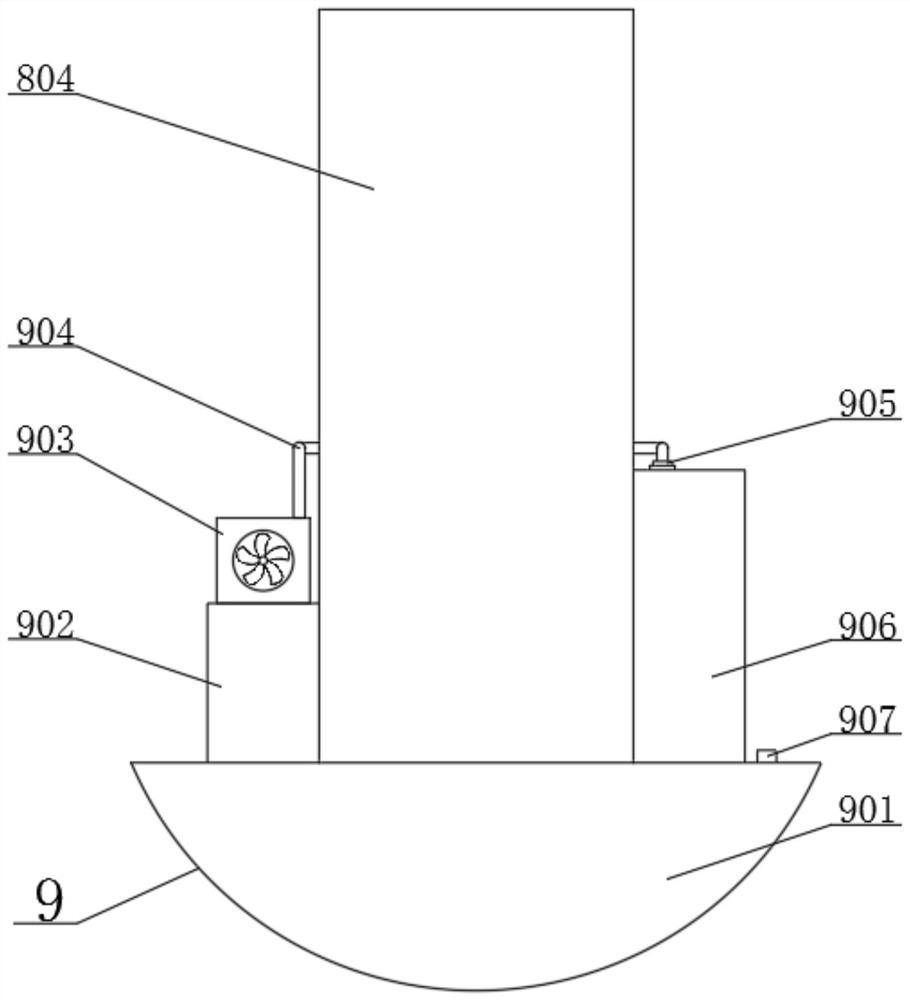

[0028] In Embodiment 2, the same parts as Embodiment 1 will not be described again, the difference is that when the axle housing 6 of the assembly cannot be located exactly above the double-outlet shaft motor 705, it will be rotated by the double-outlet shaft motor 705, thereby Drive the adjustment threaded rod 706 to rotate, and then drive the sliding sleeve 708 to move, so that the extrusion block 708 on one side contacts the axle housing first, and then the double output shaft motor 705 continues to rotate, thereby driving the slider 703 below to move, so that the adjustment The inner side of the threaded rod 706 slides with the limit column 705, so as to ensure that the axle housing 6 of the assembly can be clamped and fixed automatically without moving it, and the set limit rod 704 ensures that the slider 703 slides stably. After the collection work of the collection box 906 is completed, the clamping plate 907 is slid upwards, and then the connector 905 is removed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com