A kind of sphalerite flotation compound inhibitor and its application

A compound inhibitor, sphalerite technology, applied in flotation, solid separation and other directions, can solve the problems of low production index, environmental pollution, large chemical consumption, etc., to achieve flotation separation, high inhibition selectivity, broad The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

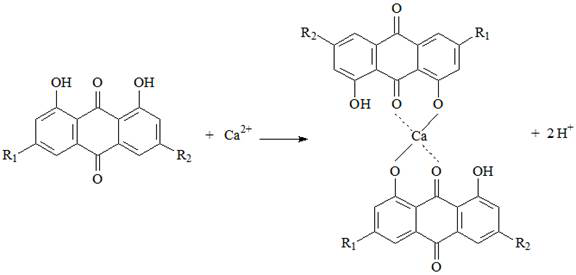

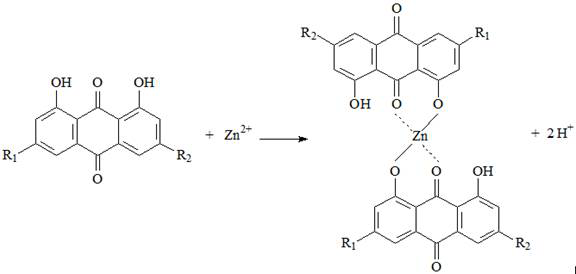

Method used

Image

Examples

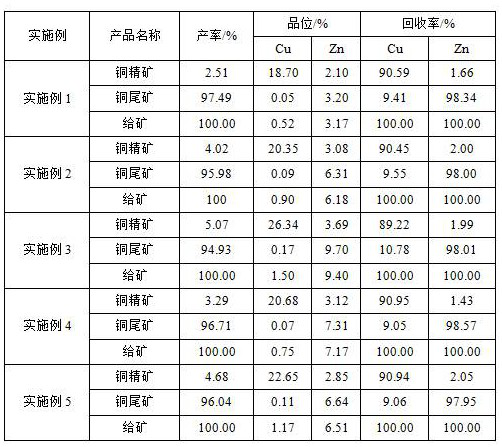

Embodiment 1

[0034] A kind of sphalerite flotation compound inhibitor, described compound inhibitor comprises organic inhibitor and inorganic inhibitor; Described organic inhibitor is emodin, and described inorganic inhibitor is ZnSO 4 and CaO, the mass ratio of the organic inhibitor to the inorganic inhibitor is 1:4, the ZnSO 4 The mass ratio of CaO and CaO is 1:1, and the total amount of composite inhibitor is 750g / t, which is added to the pulp during flotation.

[0035]The separation of sphalerite and chalcopyrite when the above composite inhibitor is used in the flotation of copper-zinc sulfide ore:

[0036] In the copper-zinc sulfide ore processed in this embodiment: the Cu grade is 0.52wt%, the Zn grade is 3.17wt%, the copper-containing mineral is mainly chalcopyrite, and the zinc-containing mineral is mainly sphalerite. The flotation steps are as follows:

[0037] (1) Grind the copper-zinc sulfide ore until the grinding fineness -0.074mm accounts for 90%, adjust the concentration o...

Embodiment 2

[0044] A kind of sphalerite flotation composite depressant, described composite depressant comprises organic depressant and inorganic depressant; Described organic depressant is chrysophanol, and described inorganic depressant is ZnSO 4 and Na 2 S 2 o 5 , the mass ratio of the organic inhibitor to the inorganic inhibitor is 1:5, and the ZnSO 4 and Na 2 S 2 o 5 The mass ratio of the compound inhibitor is 1:2, and the total dosage of the compound inhibitor is 1620g / t. The compound inhibitor is added to the pulp during flotation.

[0045] The separation of sphalerite and chalcopyrite when the above composite inhibitor is used in the flotation of copper-zinc sulfide ore:

[0046] In the copper-zinc sulfide ore treated in this embodiment: the grade of Cu is 0.90wt%, the grade of Zn is 6.13wt%, the copper-containing minerals are mainly chalcopyrite, and the zinc-containing minerals are mainly sphalerite.

[0047] Grinding fineness of copper-zinc sulfide ore -0.074mm accounts ...

Embodiment 3

[0055] A kind of sphalerite flotation compound inhibitor, described compound inhibitor comprises organic inhibitor and inorganic inhibitor; Described organic inhibitor is rhein, and described inorganic inhibitor is ZnSO 4 and Na 2 CO 3 , the mass ratio of the organic inhibitor to the inorganic inhibitor is 1:3, and the ZnSO 4 and Na 2 CO 3 The mass ratio of the compound inhibitor is 1:4, and the total dosage of the compound inhibitor is 2100g / t, and the compound inhibitor is added to the pulp during flotation.

[0056] The separation of sphalerite and chalcopyrite when the above composite inhibitor is used in the flotation of copper-zinc sulfide ore:

[0057] In the copper-zinc sulfide ore processed in this embodiment: Cu grade 1.5wt%, Zn grade 9.45wt%, copper-containing minerals are mainly chalcopyrite, zinc-containing minerals are mainly sphalerite, and the flotation conditions are as follows:

[0058] (1) Grind the copper-zinc sulfide ore until the grinding fineness -0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap