Tobacco enterprise on-site 6s management system

A management system and on-site technology, applied in the field of the tobacco industry, can solve problems such as subjective judgment, complexity, and reduced credibility in assessment, and achieve the effect of clear requirements and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

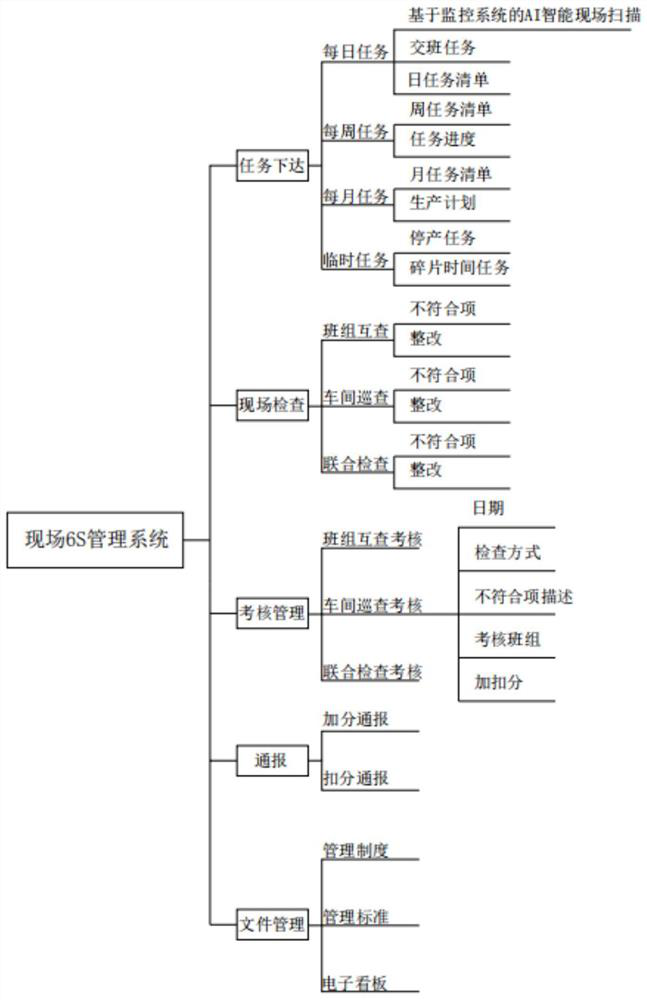

[0034] refer to figure 1 , the present embodiment is a tobacco enterprise on-site 6s management system, including:

[0035] Task issuing module, including daily task unit, weekly task unit, monthly task unit and temporary task unit, among which——

[0036] The daily task unit includes a monitoring system, an analysis system, and a review system. The monitoring system includes a camera installed on the workshop site. The analysis system includes a standard library and image recognition components. The review system is used for secondary identification of abnormal images and missing points, and Send the identified abnormal image formation daily task list to the current production team for rectification;

[0037] The weekly and monthly task lists for weekly task units and monthly task units are formulated by the production team according to the 6s management system on the workshop site, and the task lists for the next week and month are formulated at the end of each weekend and a...

Embodiment 2

[0048] refer to figure 1 , the management method of the tobacco enterprise on-site 6s management system, realize the workshop on-site 6s management through the following methods:

[0049] The system has 5 functional modules including task assignment, on-site inspection, assessment management, notification, and document management. Each functional module also has its own sub-modules, among which:

[0050] Task release includes daily tasks, weekly tasks, monthly tasks and temporary tasks;

[0051] The daily tasks include the AI intelligent on-site scanning function based on the monitoring system, the analysis system, and the review system to determine and issue a list of daily tasks that need to be rectified, including shift tasks;

[0052] The weekly task includes the weekly task list formulated by the production team according to the 6S management system on the workshop site, as well as the current task progress;

[0053] The monthly tasks include the monthly task list for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com