Two-section type conduction oil recovery heat exchanger for trough type photo-thermal power plant

A technology of heat transfer oil and power plants, which is applied in the field of trough-type photothermal power generation heat exchange equipment and heat exchange equipment, which can solve the problems of large floor area, high investment cost, and large number of equipment, so as to reduce the layout space and investment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

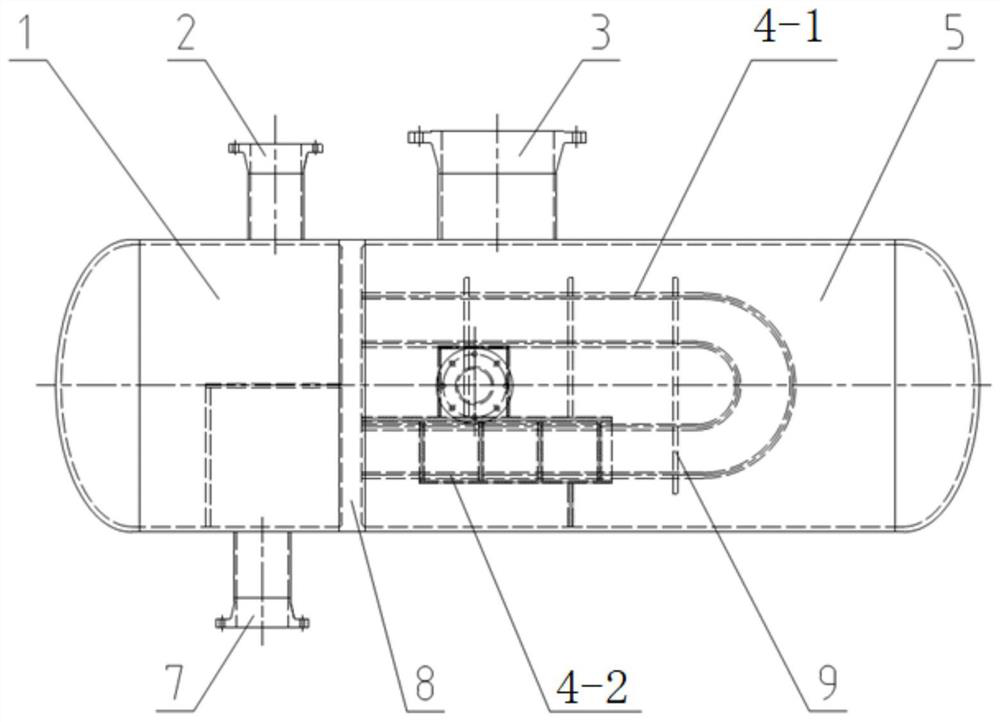

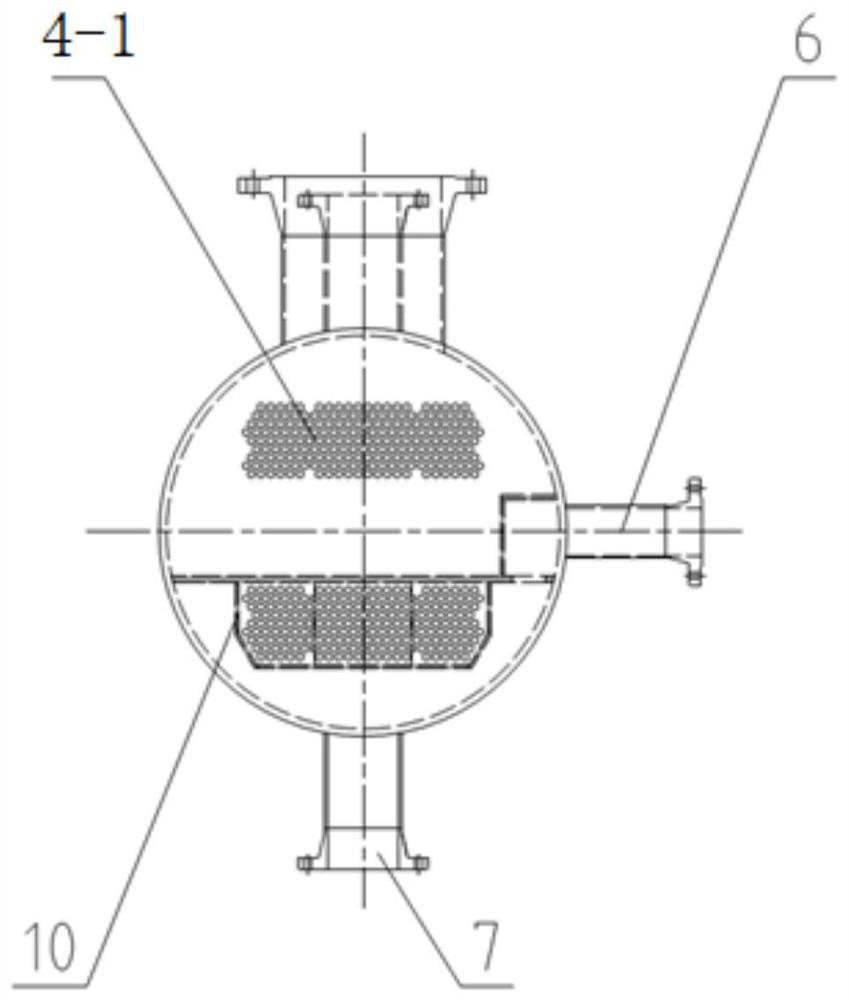

[0014] The Reclamation HEX heat exchanger in the photothermal heat transfer oil recovery system, the shell side is set as a two-stage type, in which the condensation section cools the heat transfer oil from 286°C to 264°C, and the heat exchange area is about 70m 2 ;The subcooling section supercools the heat transfer oil from 264°C to 220°C, and the heat exchange area is about 40m 2 , the heat transfer area of the whole heat exchanger is 110m 2 .

Embodiment 2

[0016] The Reclamation HEX vent heat exchanger in the photothermal heat transfer oil recovery system, the shell side is set as a two-stage type, in which the condensation section cools the heat transfer oil from 286°C to 264°C, and the heat exchange area is about 1.127m 2 ;The subcooling section supercools the heat transfer oil from 264°C to 220°C, and the heat transfer area is about 0.532m 2 , the heat transfer area of the whole heat exchanger is 1.659m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com