Novel matched pipe of exhaust pipe, derivative structure, passenger car air conditioner compressor and simulation method

An air-conditioning compressor and simulation method technology, applied in design optimization/simulation, mechanical equipment, vehicle parts, etc., can solve the secondary cost of increasing welding process man-hours, welding labor posts, welding materials, etc., and the impact of manufacturing and assembly time on project development progress, reducing the service life of air conditioners, etc., to achieve the effect of solving the transportation stress and strain exceeding the standard, reducing the cost of material procurement, and reducing the cost of piping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

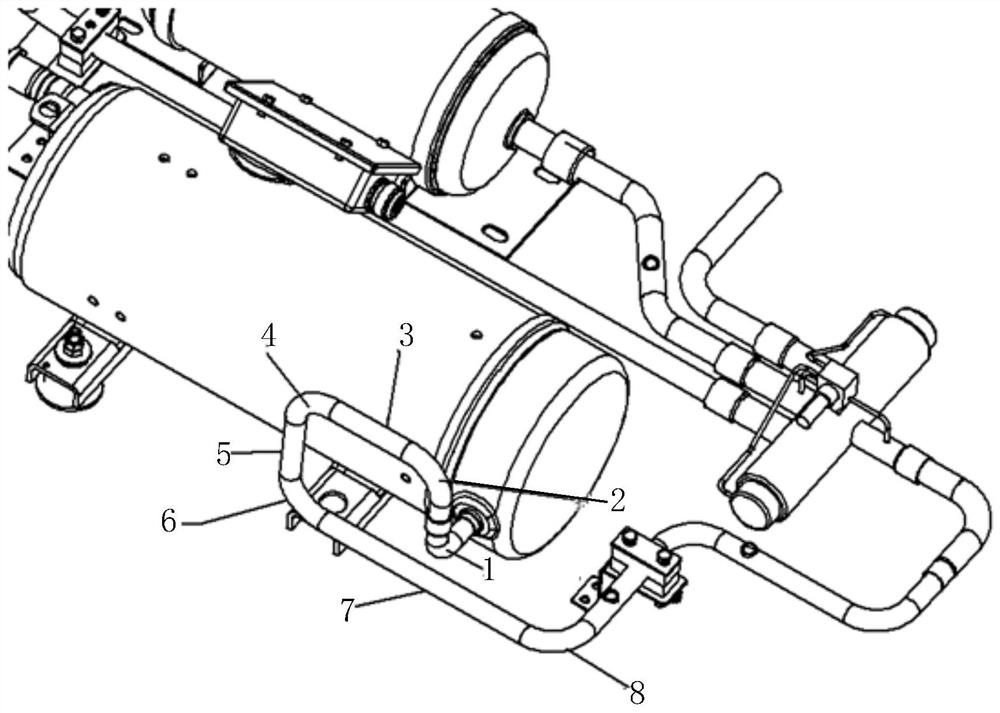

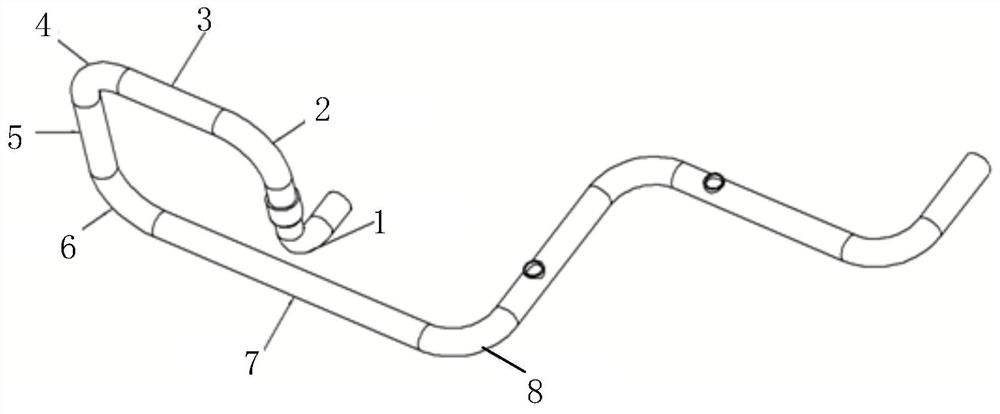

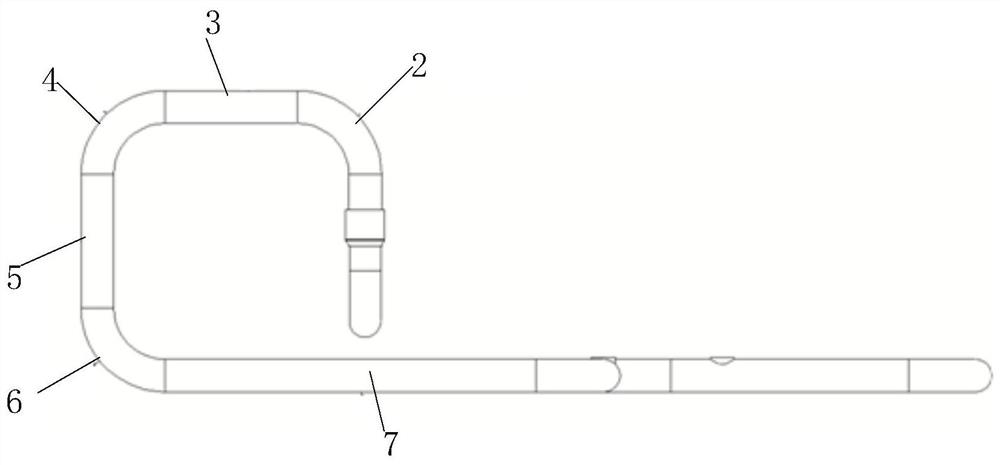

[0041] Aiming at the problems existing in the prior art, the present invention provides a new type of exhaust pipe piping, a derivative structure, a passenger car air-conditioning compressor and a simulation method. The present invention obtains a new type of exhaust pipe by combining CAE simulation with experimental testing. Passenger car air-conditioning piping scheme, the piping scheme has simple production process, low cost and high production efficiency. Simultaneously, the present invention provides two kinds of compressor exhaust pipe piping schemes, a novel passenger car air-conditioning piping scheme that reduces p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com