Electrified cleaning agent for high-pressure jet cleaning and preparation method ofelectrified cleaning agent

A technology of high-pressure spraying and cleaning agent, which is applied in the directions of detergent compounding agent, detergent composition, chemical instrument and method, etc., can solve the problems of affecting cleaning effect and poor penetration, so as to improve cleaning effect, improve penetration effect, The effect of enhancing the anti-fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

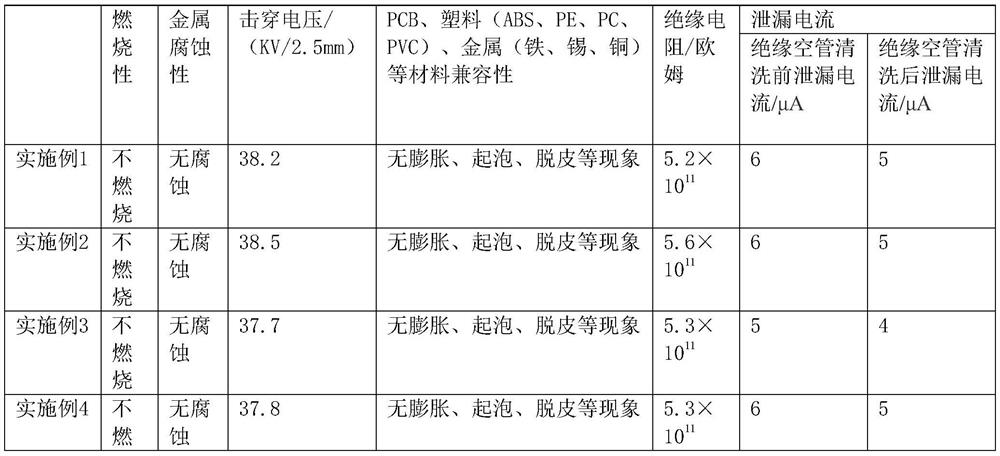

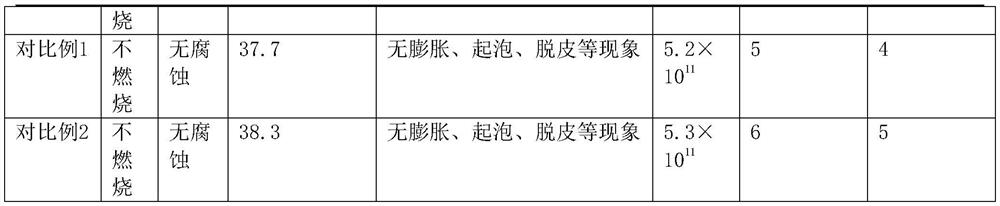

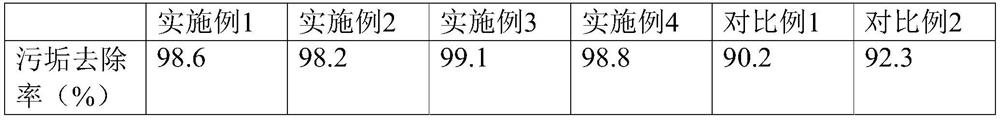

Examples

Embodiment 1

[0023] A charged cleaning agent for high-pressure jet cleaning, comprising 2 parts of cleaning material, 50 parts of dipropylene glycol, 6 parts of ethanol, 10 parts of simethicone, 10 parts of nonionic surfactant, and 0.1 part of antifungal agent in parts by weight , 0.2 parts of antistatic agent.

[0024] The cleaning material is silicon dioxide.

[0025] The nonionic surfactant is a polyol type nonionic surfactant, specifically Span S80.

[0026] The fungicide is dithiocyanomethane.

[0027] The antistatic agent is an externally coated cationic antistatic agent, specifically the American cyanate antistatic agent CYASTATSN.

[0028] Its preparation method comprises the following steps:

[0029] (1) Mix cleaning material, dipropylene glycol, ethanol and non-ionic surfactant evenly, disperse by ultrasonic for 2min, ultrasonic temperature 30-40℃, frequency 100KHz;

[0030] (2) Then add simethicone oil, antifungal agent and antistatic agent, ultrasonic dispersion 3m, ultraso...

Embodiment 2

[0032] A charged cleaning agent for high-pressure jet cleaning, comprising 8 parts of cleaning material, 60 parts of dipropylene glycol, 9 parts of ethanol, 20 parts of simethicone, 14 parts of nonionic surfactant, and 0.3 parts of antifungal agent in parts by weight , 0.6 parts of antistatic agent.

[0033] The cleaning material is silicon dioxide.

[0034] The nonionic surfactant is a polyol type nonionic surfactant, specifically Span S80.

[0035] The fungicide is dithiocyanomethane.

[0036] The antistatic agent is an externally coated cationic antistatic agent, specifically the American cyanate antistatic agent CYASTATSN.

[0037] Its preparation method comprises the following steps:

[0038] (1) Mix the cleaning material, dipropylene glycol, ethanol and non-ionic surfactant evenly, disperse by ultrasonic for 1min, ultrasonic temperature 30-40℃, frequency 120KHz;

[0039] (2) Then add simethicone oil, antifungal agent and antistatic agent, ultrasonic dispersion 5m, ul...

Embodiment 3

[0041] A charged cleaning agent for high-pressure jet cleaning, comprising 5 parts of cleaning material, 55 parts of dipropylene glycol, 5 parts of ethanol, 15 parts of simethicone, 8 parts of nonionic surfactant, and 0.4 parts of antifungal agent in parts by weight , 0.4 parts of antistatic agent.

[0042] The cleaning material is silicon nitride.

[0043] The nonionic surfactant is a polyol type nonionic surfactant, specifically Span S60.

[0044] The fungicide is dithiocyanomethane.

[0045] The antistatic agent is an external coating type cationic antistatic agent, and the Weihai overseas coating type antistatic agent K-44 is used.

[0046] Its preparation method comprises the following steps:

[0047] (1) Mix cleaning material, dipropylene glycol, ethanol and non-ionic surfactant evenly, disperse by ultrasonic for 2min, ultrasonic temperature 30-40℃, frequency 120KHz;

[0048] (2) Then add simethicone oil, antifungal agent and antistatic agent, ultrasonic dispersion 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com