A kind of metal ion transfer carrier and its preparation method and application

A metal ion, transfer carrier technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc. problem, to achieve the effect of simple preparation method and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for preparing a metal ion transfer carrier, which includes the following steps in sequence:

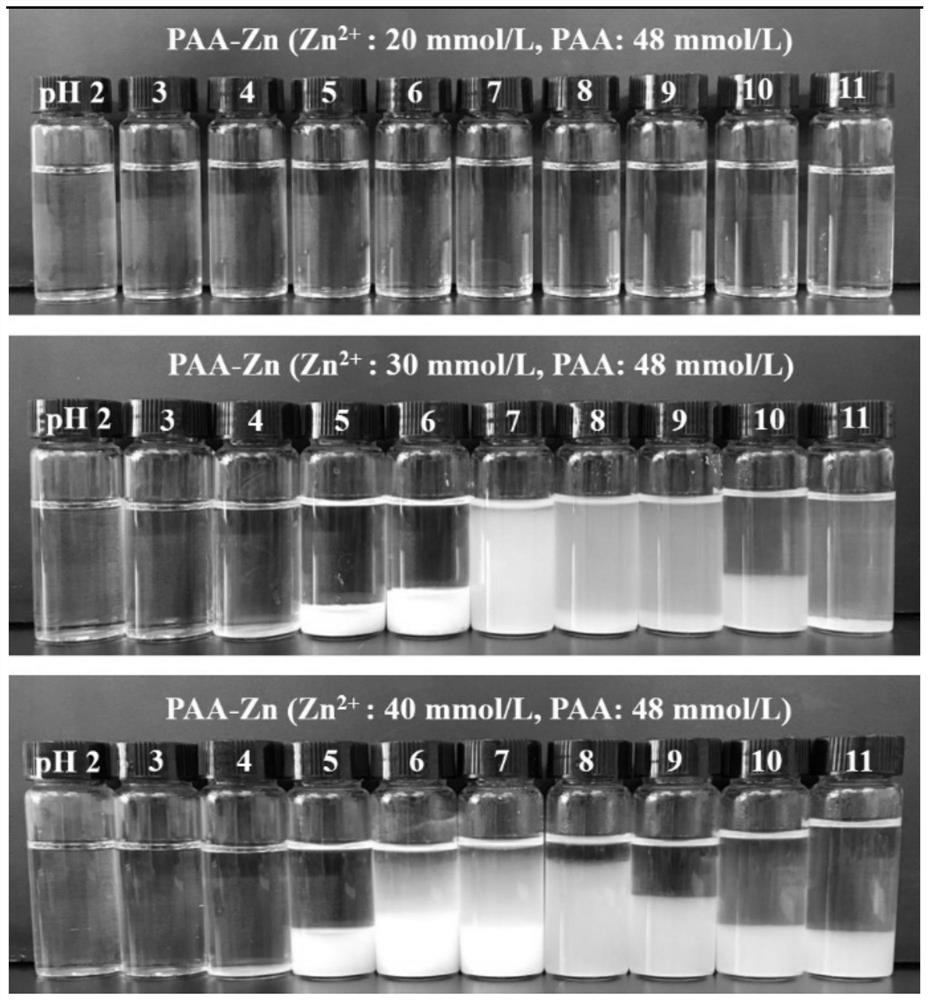

[0047] (1) The water-soluble compound containing carboxyl group in the present embodiment is polyacrylic acid (PAA), and the weight-average molecular weight is 125000g / mol, and the preparation molar concentration is the polyacrylic acid aqueous solution of 48mmol / L;

[0048] (2) Dissolve zinc sulfate in water, add polyacrylic acid aqueous solution to prepare mixed solution, the molar concentration of metal zinc ions in the mixed solution is 20mmol / L, and mix well. Regulate the pH value of mixed solution with 2.5mol / L sodium hydroxide solution to be 7;

[0049] (3) Concentrate the mixed solution with a rotary evaporator to a zinc ion concentration of 50 mmol / L to obtain a metal ion transfer carrier.

Embodiment 2

[0051] This embodiment provides a method for preparing a metal ion transfer carrier, which includes the following steps in sequence:

[0052] (1) The water-soluble compound containing carboxyl group in the present embodiment is polyacrylic acid (PAA), and the weight-average molecular weight is 125000g / mol, and the preparation molar concentration is the polyacrylic acid aqueous solution of 55mmol / L;

[0053] (2) Dissolving zinc sulfate in water, adding it to polyacrylic acid aqueous solution to prepare a mixed solution, the molar concentration of zinc ions in the mixed solution is 25mmol / L, and mixed uniformly. Regulate the pH value of mixed solution with 2.5mol / L sodium hydroxide solution to be 8;

[0054] (3) Concentrate the mixed solution with a rotary evaporator until the concentration of zinc ions is 60 mmol / L to obtain a metal ion transfer carrier.

Embodiment 3

[0056] This embodiment provides a method for preparing a metal ion transfer carrier, which includes the following steps in sequence:

[0057] (1) The water-soluble compound containing carboxyl in the present embodiment is polyacrylic acid (PAA), and the weight-average molecular weight is 100000g / mol, and the preparation molar concentration is the polyacrylic acid aqueous solution of 65mmol / L;

[0058] (2) Dissolve copper sulfate in water, add polyacrylic acid aqueous solution to prepare a mixed solution, the molar concentration of copper ions in the mixed solution is 10mmol / L, and mix well. Regulate the pH value of mixed solution with 2.5mol / L sodium hydroxide solution to be 7;

[0059] (3) Concentrate the mixed solution with a rotary evaporator to a copper ion concentration of 60 mmol / L to obtain a metal ion transfer carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com