Low-shrinkage and low-viscosity C80 high-strength pump concrete and preparation method thereof

A technology for pumping concrete and high-strength concrete, applied in the field of building materials, can solve the problems of lack of high-cementing material volume stability, lack of high-strength concrete over-stick, poor volume stability, etc., to improve volume stability, appearance quality improvement, The effect of improved crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

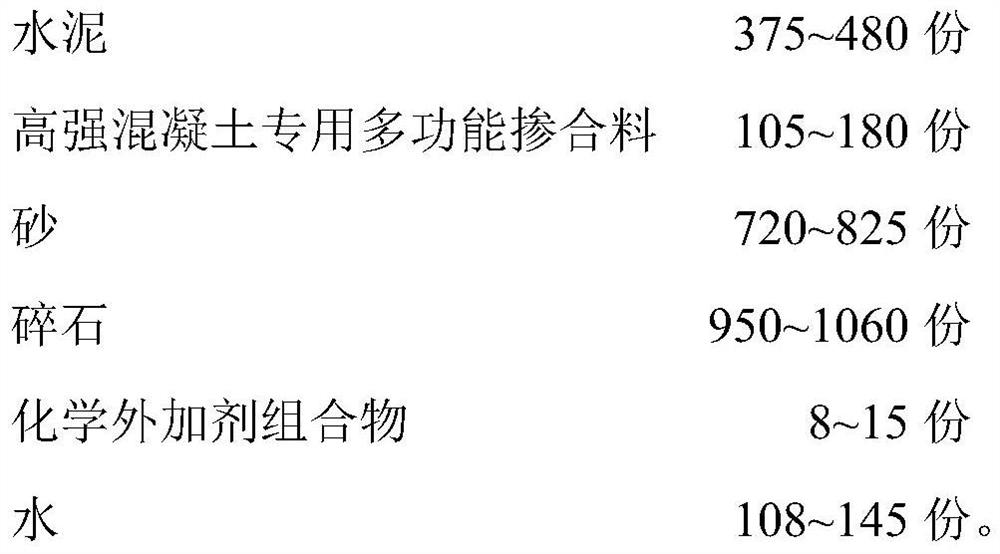

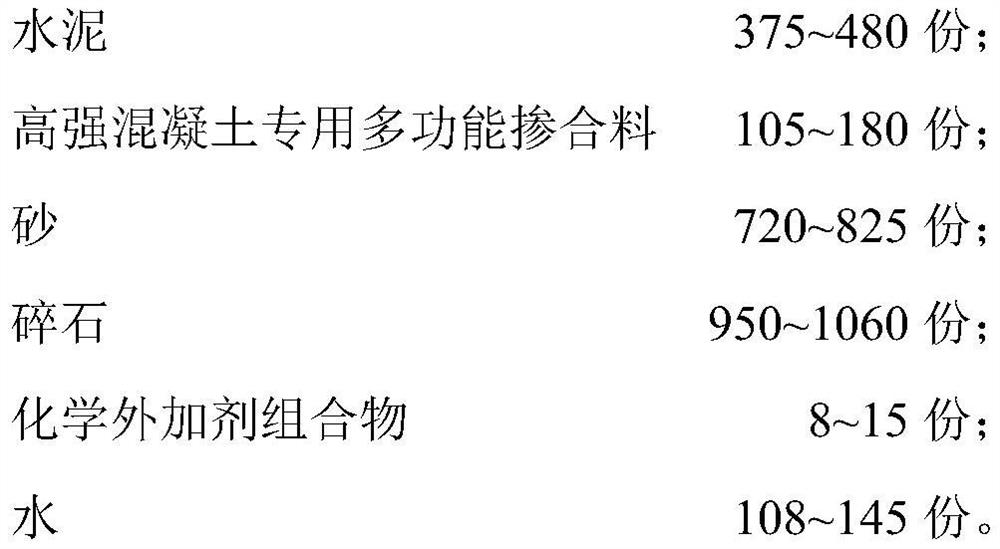

[0030] A low-shrinkage and low-viscosity C80 high-strength pump concrete and a preparation method thereof,

[0031] The parts by weight of each component are: 432 parts of cement, 108 parts of multifunctional admixture for high-strength concrete, 795 parts of sand, 1012 parts of gravel, 13.5 parts of chemical admixture composition, and 119 parts of water;

[0032] Among them, the mass percentage of each component of the special multifunctional admixture for high-strength concrete is: nano-calcium carbonate 0.7%, nano-calcium silicate hydrate 1%, micro-silica fume 20%, fly ash micro-beads 20%, mineral powder 23.767 %, calcium oxide expansion agent 15%, magnesium oxide expansion agent 15%, maleic anhydride ester 0.03%, neopentyl glycol 4.5%, tributyl phosphate 0.003%.

[0033] The mass percent of each component of the chemical admixture composition is: 35% of small molecular weight polycarboxylate water reducer, 20% of slow release polycarboxylate water reducer, 3% of sodium glu...

Embodiment 2

[0035] A low-shrinkage and low-viscosity C80 high-strength pump concrete and a preparation method thereof,

[0036] The parts by weight of each component are: 420 parts of cement, 140 parts of multifunctional admixture for high-strength concrete, 782 parts of sand, 996 parts of gravel, 12.88 parts of chemical admixture composition, and 129 parts of water;

[0037] Among them, the mass percentage of each component of the special multifunctional admixture for high-strength concrete is: nano-calcium carbonate 0.7%, nano-calcium silicate hydrate 1%, micro-silica fume 20%, fly ash micro-beads 20%, mineral powder 23.767 %, calcium oxide expansion agent 15%, magnesium oxide expansion agent 15%, maleic anhydride ester 0.03%, neopentyl glycol 4.5%, tributyl phosphate 0.003%.

[0038] The mass percent of each component of the chemical admixture composition is: 35% of small molecular weight polycarboxylate water reducer, 20% of slow release polycarboxylate water reducer, 3% of sodium gluco...

Embodiment 3

[0040] A low-shrinkage and low-viscosity C80 high-strength pump concrete and a preparation method thereof,

[0041] The parts by weight of each component are: 413 parts of cement, 177 parts of multifunctional admixture for high-strength concrete, 764 parts of sand, 973 parts of gravel, 11.8 parts of chemical admixture composition, and 141 parts of water;

[0042] Among them, the mass percentage of each component of the special multifunctional admixture for high-strength concrete is: nano-calcium carbonate 0.7%, nano-calcium silicate hydrate 1%, micro-silica fume 20%, fly ash micro-beads 20%, mineral powder 23.767 %, calcium oxide expansion agent 15%, magnesium oxide expansion agent 15%, maleic anhydride ester 0.03%, neopentyl glycol 4.5%, tributyl phosphate 0.003%.

[0043] The mass percent of each component of the chemical admixture composition is: 35% of small molecular weight polycarboxylate water reducer, 20% of slow release polycarboxylate water reducer, 3% of sodium gluc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com