Bubble removing equipment for uniform processing of glass

A uniform and equipment technology, which is applied in the field of defoaming equipment for uniform glass processing, can solve problems such as inconvenient defoaming, and achieve the effects of increased defoaming effect, uniform heating and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

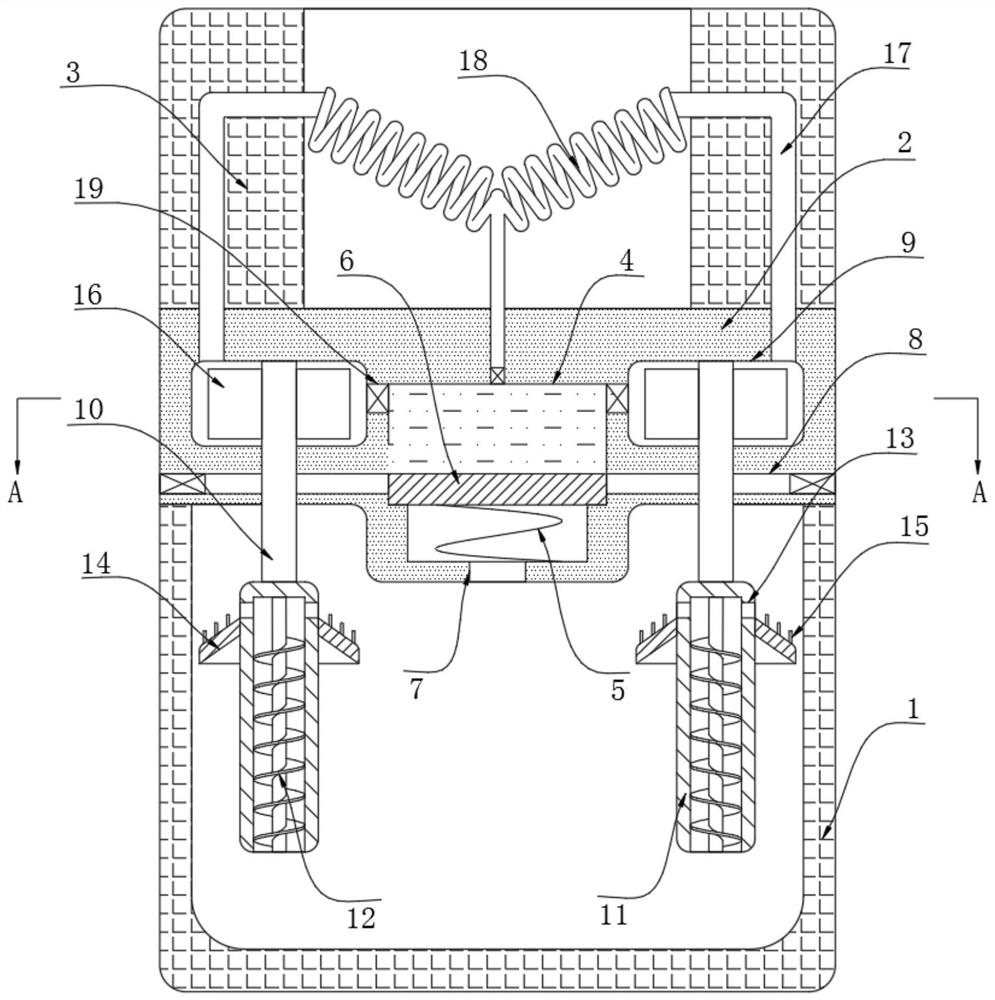

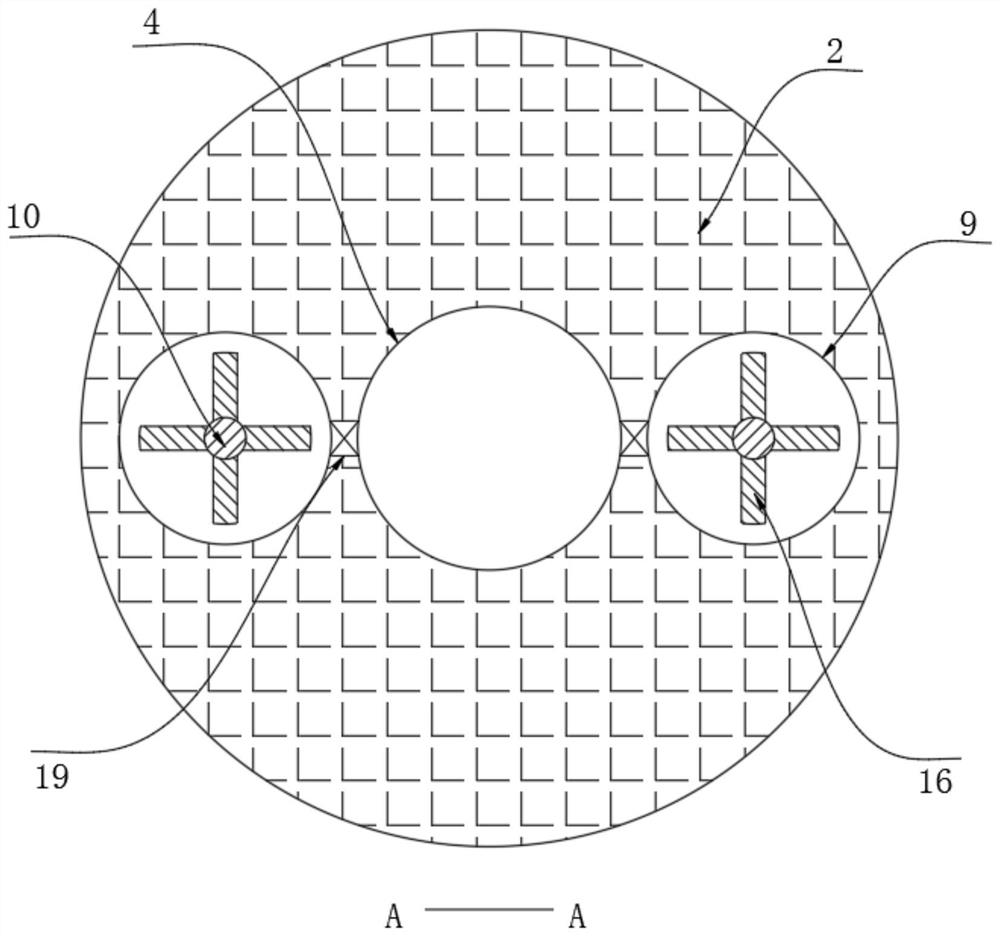

[0018] refer to Figure 1-2 , a defoaming device for uniform processing of glass, comprising a melting tank (1), the upper end of the melting tank (1) is fixed with a conversion plate (2), and the upper end of the conversion plate (2) is fixed with a water storage tank (3) , the inside of the conversion plate (2) is provided with a pumping chamber (4), the inner bottom of the pumping chamber (4) is connected with the push plate (6) through the return spring (5), and the inner bottom of the pumping chamber (4) runs through a replacement The air hole (7), the side wall of the pumping chamber (4) is provided with a plurality of exhaust holes (8), the inside of the conversion plate (2) is provided with a plurality of conveying grooves (9), and the inside of the pumping chamber (4) A plurality of driving grooves (19) correspondingly connected with a plurality of delivery grooves (9) are opened through, and a return pipe (18) connected with the inside of the pumping chamber (4) is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com