Method for repairing interface layering defects of fiber winding engine shell body

A technology for engine casing and delamination defects, which is applied in the direction of climate sustainability, sustainable transportation, air transportation, etc., and can solve the problems of casing shape and position tolerance, affecting the strength of composite layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

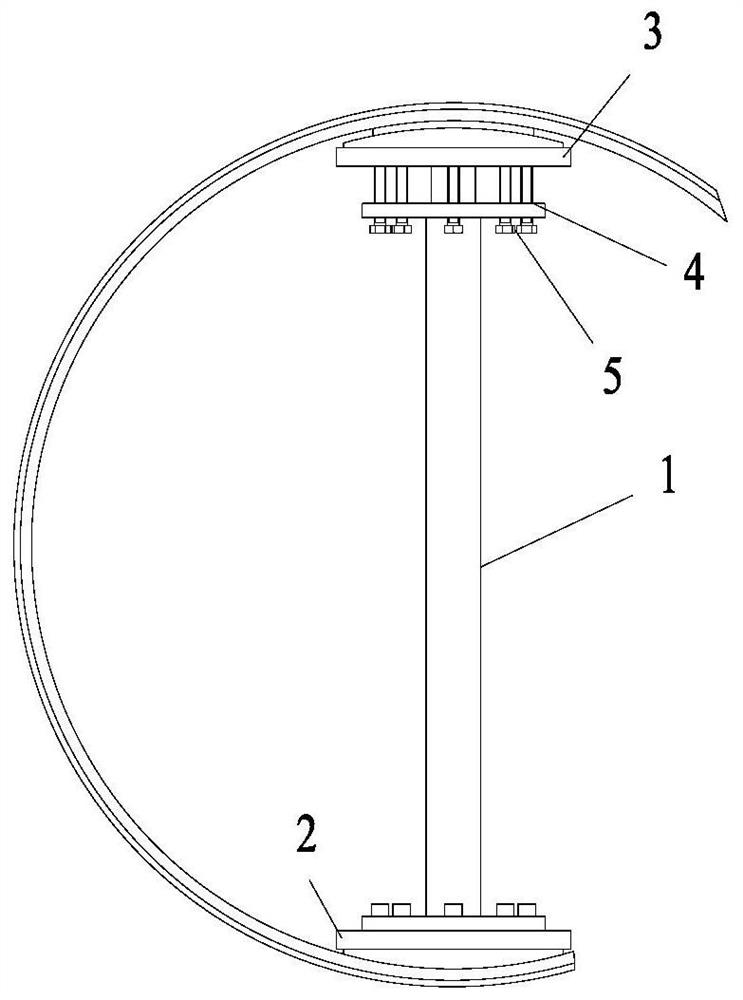

[0087] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0088] The method for repairing interface delamination defects of filament wound engine shells is especially suitable for debonding repairs where the insulation layer is more than 10mm. The repair of interface delamination defects includes defect identification, defect removal, composite layer reset, cold adhesive repair and hot adhesive repair. Specific steps are as follows:

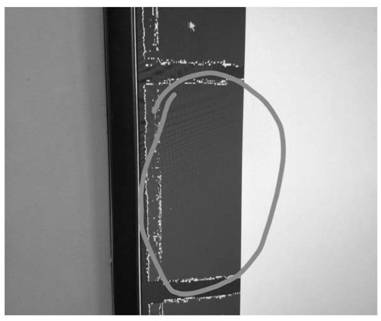

[0089] 1) Ultrasonic testing followed by DR testing to accurately locate the position of the interface delamination defect, and draw a defect edge marking line on the surface of the thermal insulation layer

[0090] In order to accurately define the defect location, during the ultrasonic inspection process, glue mold cloth is pasted on the edge of the interface delamination defect to make the defect, which is used as a reference for the definition of the defect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com