Anti-shocking type accurate carving device for machine manufacturing

A kind of mechanical manufacturing and anti-seismic technology, which is applied in the direction of positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of increased workload, increased processing tolerance, and no material turning, so as to reduce the number of clamping times and reduce the Machining tolerance and effect of improving machining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

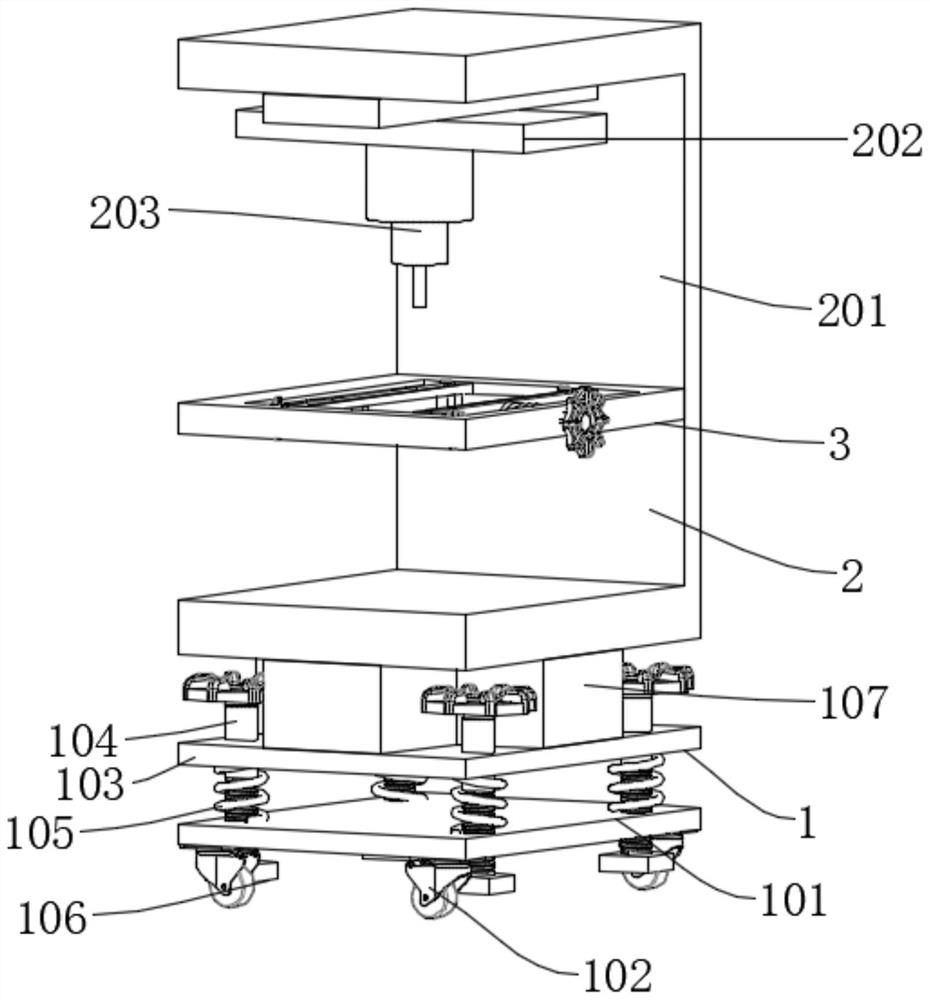

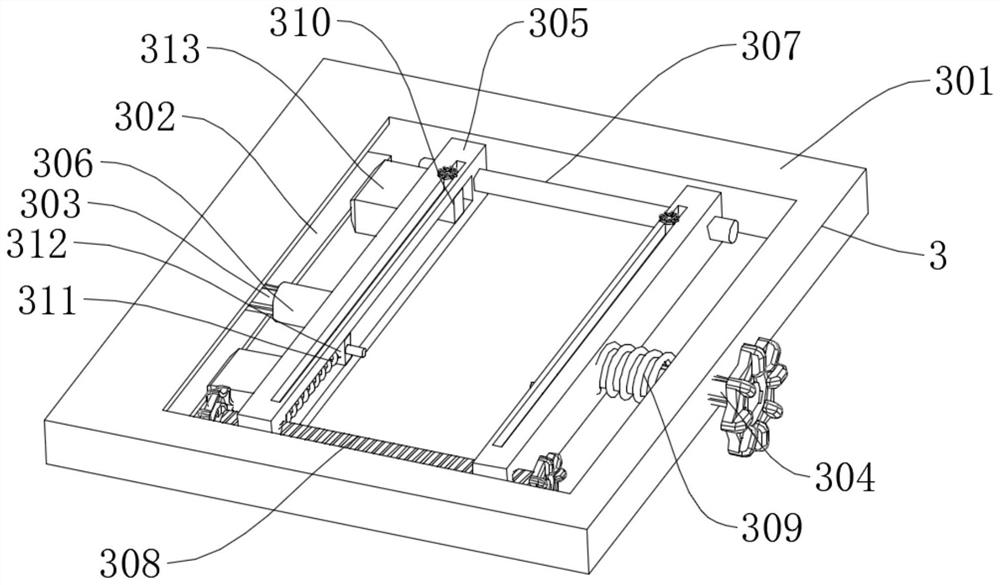

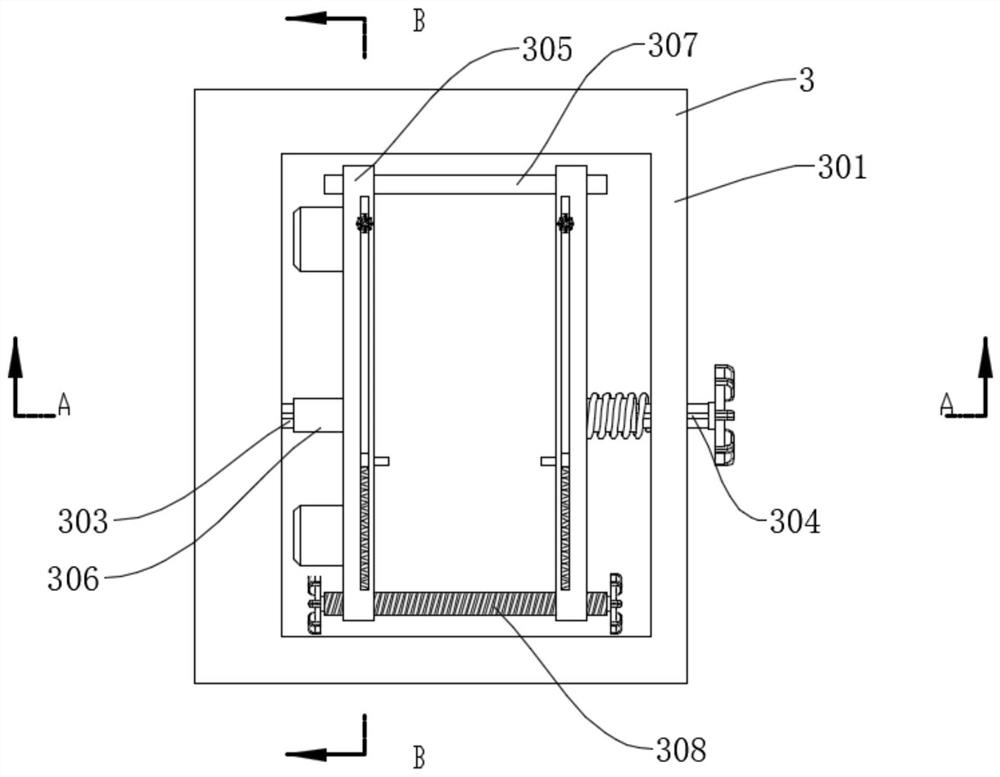

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, an anti-seismic engraving device for mechanical manufacturing includes a shock-absorbing mechanism 1, an engraving machine body 2, and a clamp 3. The clamp 3 includes a fixing frame 301, a connecting rod 303, a flange turntable 304, and a mounting rod 305, sliding sleeve 306, guide rod 307, positive and negative lead screw 308, back-moving spring 309, longitudinal positioning block 310, fixed frame 301 is connected to the cabinet inner side of engraving machine body 2 by bolt, and fixed frame 301 inner side is provided with two relative Mounting rods 305 are provided, and two mounting rods 305 are provided with card slots on the opposite surfaces. The top of the card slots is provided with a bar-shaped slot for giving way, and the inner rear end of the card slot is slidably connected with a longitudinal positioning block 310. The longitudinal positioning block 310 The inner bolt ...

Embodiment 2

[0037] Such as Figure 7 and Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the positioning assembly includes a positioning hole 31, a limit rod 32, and a relief groove 33, and the limit rod 32 is welded on the mounting rod 305 away from the flange turntable 304, And the positioning hole 31 is opened on the inner wall of the fixed mount 301 away from the flange rotating disk 304, and the position corresponds to the stop rod 32, and the relief groove 33 is opened on the inner wall of the fixed mount 301 away from the flange rotating disk 304, and the position is Corresponding to the positive and negative lead screw 308, such a setting can prevent the installation rod 305 from rotating by snapping the limit rod 32 inside the positioning hole 31, and can also reach the bottom of the positioning hole 31 by the limit rod 32 to realize the horizontal adjustment of the installation rod 305. The positioning, and then realize the longitudinal position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com