A kind of mixing device and method for clotrimazole cream production

A mixing device, clotrimazole technology, applied in the field of mixing devices for the production of clotrimazole cream, can solve the problems of cream liquid adhesion, waste of cream medicine, affecting production quality, etc., so as to avoid stirring dead angle and increase mixing speed , Improve the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

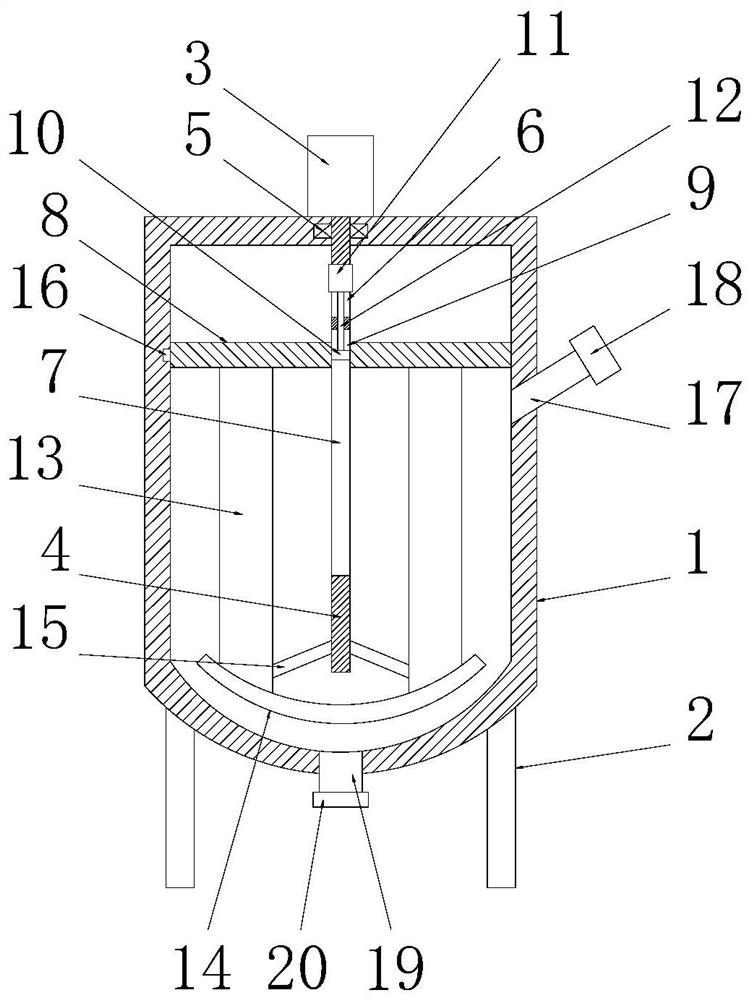

[0035] See Figure 1-3 , a mixing device for the production of clotrimazole emulsifiable paste, comprising a kettle body 1, the bottom of the kettle body 1 is evenly provided with several legs 2, and the bottom of the kettle body 1 is connected to a discharge pipe 19 through, and the The bottom end of the discharge pipe 19 is covered with a second sealing cover 20, and the cream that has been stirred in the inner cavity of the kettle body 1 is discharged through the discharge pipe 19, and the discharge work can be completed;

[0036] The top of the kettle body 1 is fixedly connected to the mixing motor 3, the inner cavity of the kettle body 1 is provided with a stirring rod 4, the axis of the kettle body 1 coincides with the axis of the stirring rod 4, and the top of the stirring rod 4 runs through the bottom of the kettle body 1. The top wall is rotatably connected to the mixing motor 3, the stirring rod 4 is rotatably connected to the kettle body 1 through the bearing 5, the...

Embodiment 2

[0042] See Figure 4 , The difference from Embodiment 1 is that the stirring belt 13 includes a first base belt 131, a second base belt 133, a third base belt 136, a first waterproof membrane 132, a second waterproof membrane 134, a third waterproof membrane 135 and a first waterproof membrane 135. Four waterproof membranes 137, the first base belt 131 is made of nylon webbing, the top of the first base belt 131 is provided with a first waterproof membrane 132, and the bottom end of the first base belt 131 is provided with a third waterproof membrane 135, so Both the first waterproof membrane 132 and the third waterproof membrane 135 are made of polyester film, the top of the first waterproof membrane 132 is provided with a second base belt 133, and the second base belt 133 is made of nylon webbing, The top of the second baseband 133 is provided with a second waterproof membrane 134, the second waterproof membrane 134 is made of PVA coated high barrier film, the bottom end of ...

Embodiment 3

[0044] See Figure 5 The difference from Embodiment 1 is that the stirring blade 14 includes a blade plate 141, the blade plate 141 is arranged in an arc-shaped structure, and the left and right sides of the concave surface of the blade plate 141 are symmetrically provided with fixed plates 142, and the fixed plate The top end of 142 is provided with the mounting groove 143 that matches with stirring belt 13, and described connecting rod 15 is fixedly connected on the concave surface of blade plate 141, and described blade plate 141 is provided with stirring hole 144, and described stirring hole 144 runs through connecting blade. The front and rear end surfaces of the plate 141, the stirring hole 144 is an arc-shaped hole, the blade plate 141 is driven to rotate by the stirring rod 4 and the connecting rod 15, and then the blade plate 141 is used to stir the raw material at the bottom of the inner cavity of the kettle body 1, which can effectively prevent the dead angle of stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com