Absorption tower slurry pool disturbance device

The technology of slurry pool and absorption tower is applied in the field of slurry pool disturbance device of absorption tower, which can solve the problems of easy wear and leakage of oil seals of mixers, reduce the quality of subsequent crystals, and easy to corrode, so as to reduce the influence of oxidation and crystallization, and improve the dust removal efficiency. , The effect of low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

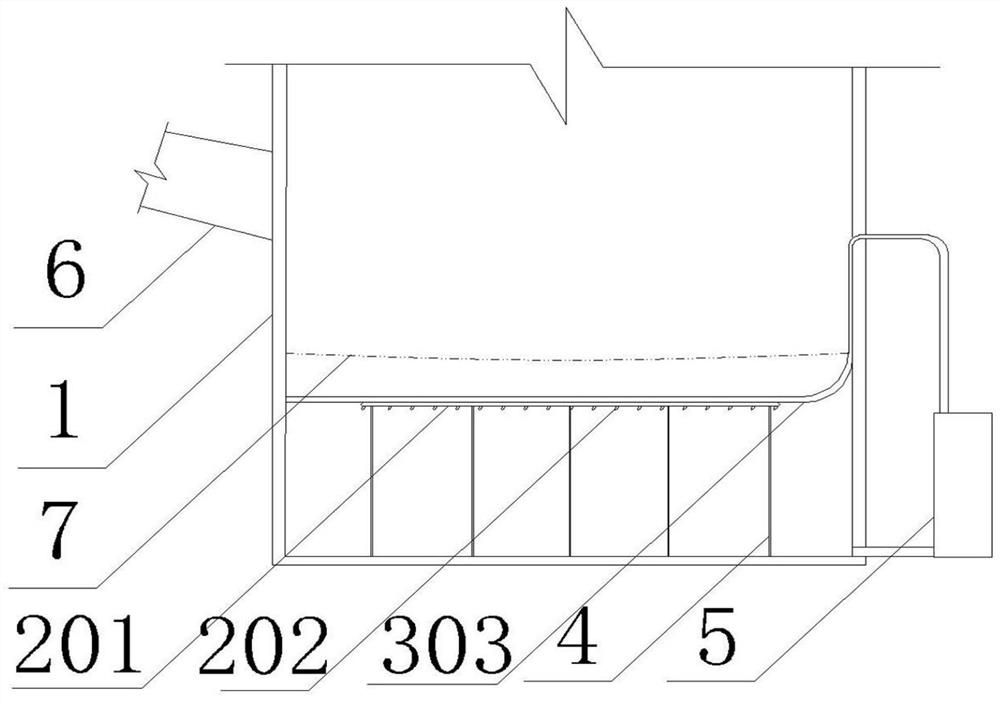

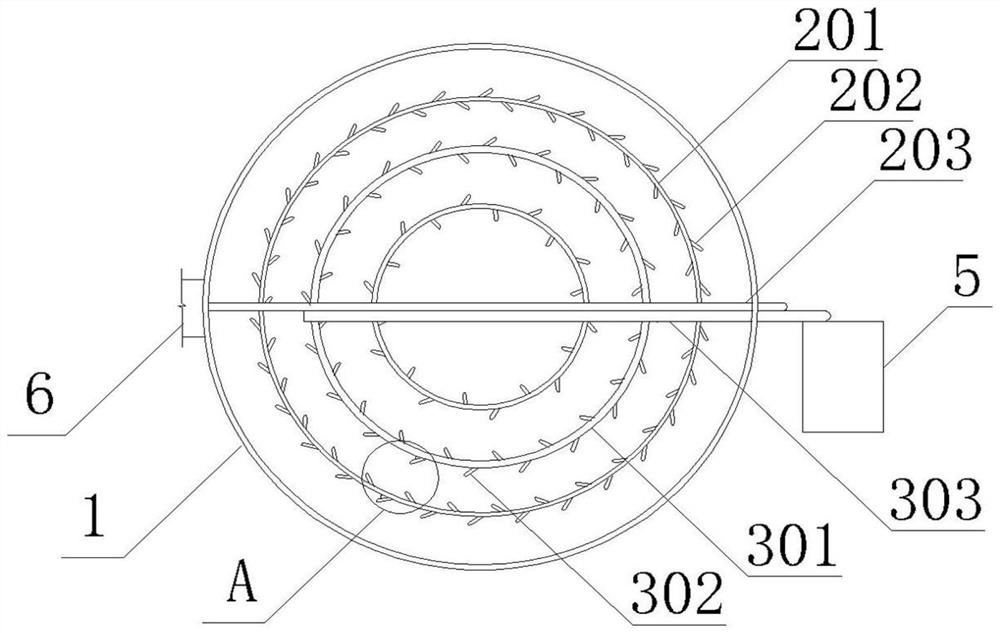

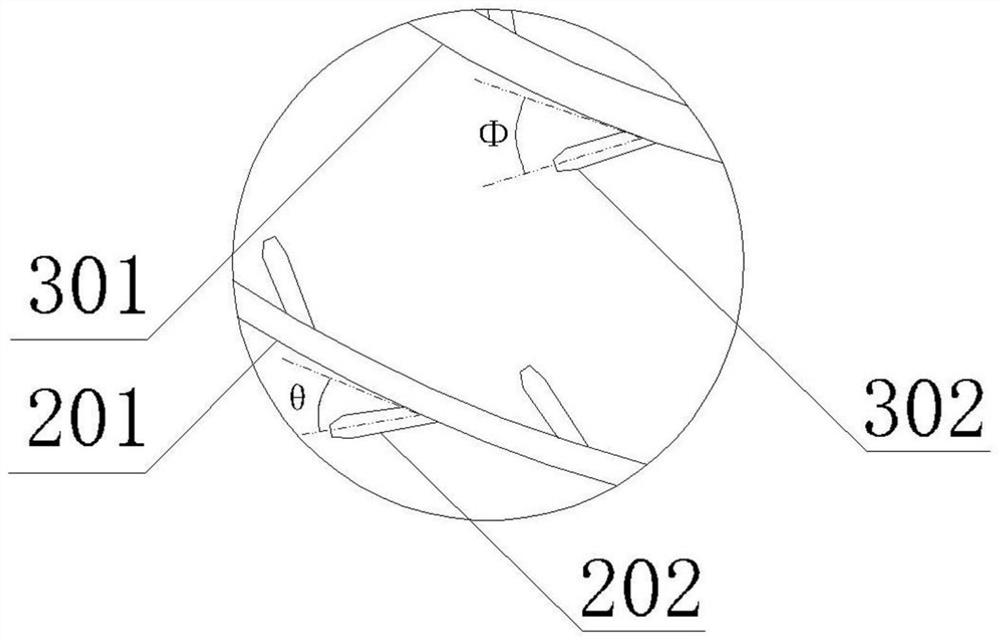

[0017] as attached Figure 1~4 The present invention shown includes a gas turbulence device arranged in a circular slurry tank 1, the gas turbulence device includes a gas distribution pipe 201, an air nozzle 202, and a gas distribution pipe 203, and the gas distribution pipe 203 is annularly arranged in the slurry tank 1 and Concentric with the slurry tank, the air nozzle 202 is arranged on the air distribution pipe 201, the angle between the air nozzle 202 and the air distribution pipe 201 is θ and less than 90 degrees, and the nozzle of the air nozzle 202 is located below the slurry liquid level, so The gas distribution pipe 201 is connected with the gas distribution pipe 203, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com