Polytetrafluoroethylene packing treatment device

A processing device, the fourth technology, applied in transportation and packaging, drying solid materials, drying gas arrangement, etc., can solve problems such as inability to dry internal and external surfaces, difficulty in applying force, low efficiency of manual cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

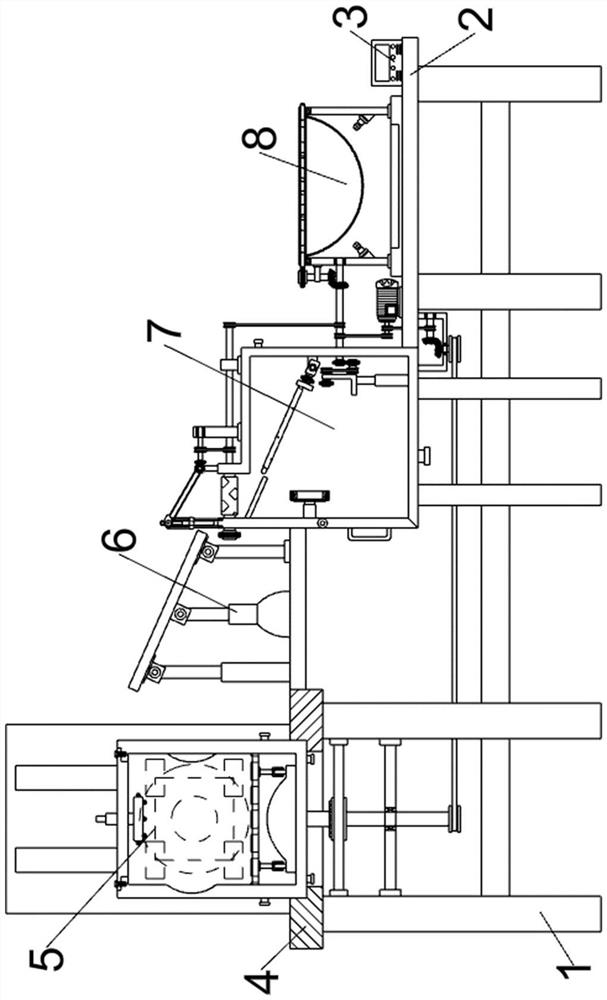

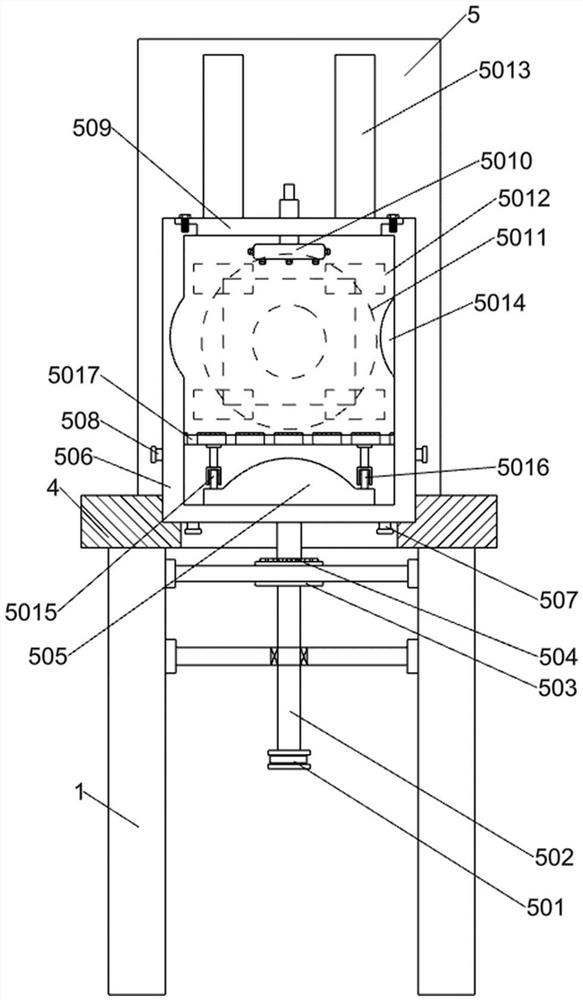

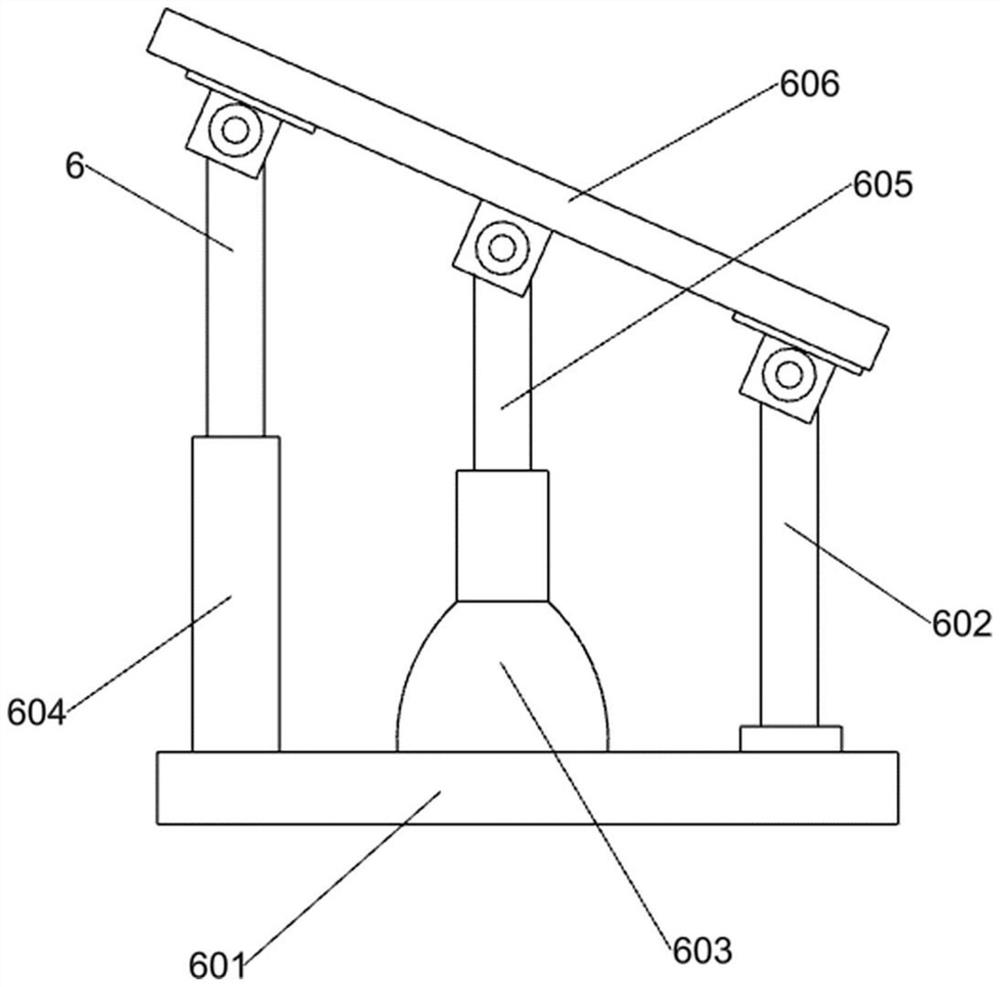

[0026] A tetrafluoro packing treatment device, such as Figure 1-6 As shown, it includes a work frame plate 1, a work table plate 2, an operation control panel 3, an embedded fixed work table 4, a mixing mechanism 5, a blanking control mechanism 6, a cleaning mechanism 7 and a drying mechanism 8; the work frame plate 1 The upper side is connected with the workbench 2, and the other side above the work frame 1 is connected with the embedded fixed workbench 4; the upper side of the workbench 2 is provided with a running control panel 3; the work frame 1 is connected with the mixing mechanism 5 is connected; the bottom of the mixing mechanism 5 is connected with the embedded fixed workbench 4; the embedded fixed workbench 4 is connected with the blanking control mechanism 6; the mixing mechanism 5 is connected with the drying mechanism 8; the blanking control mechanism 6 is connected with the cleaning mechanism 7 The bottom of the cleaning mechanism 7 is connected with the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com