PBS/PP two-component melt-blown fiber filtering material and preparation method thereof

A melt-blown fiber and filter material technology, which is applied in the PBS/PP two-component melt-blown fiber filter material and its manufacturing field, can solve problems such as low filtration efficiency, large water consumption, and affecting stable operation of the system, and achieve high filtration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

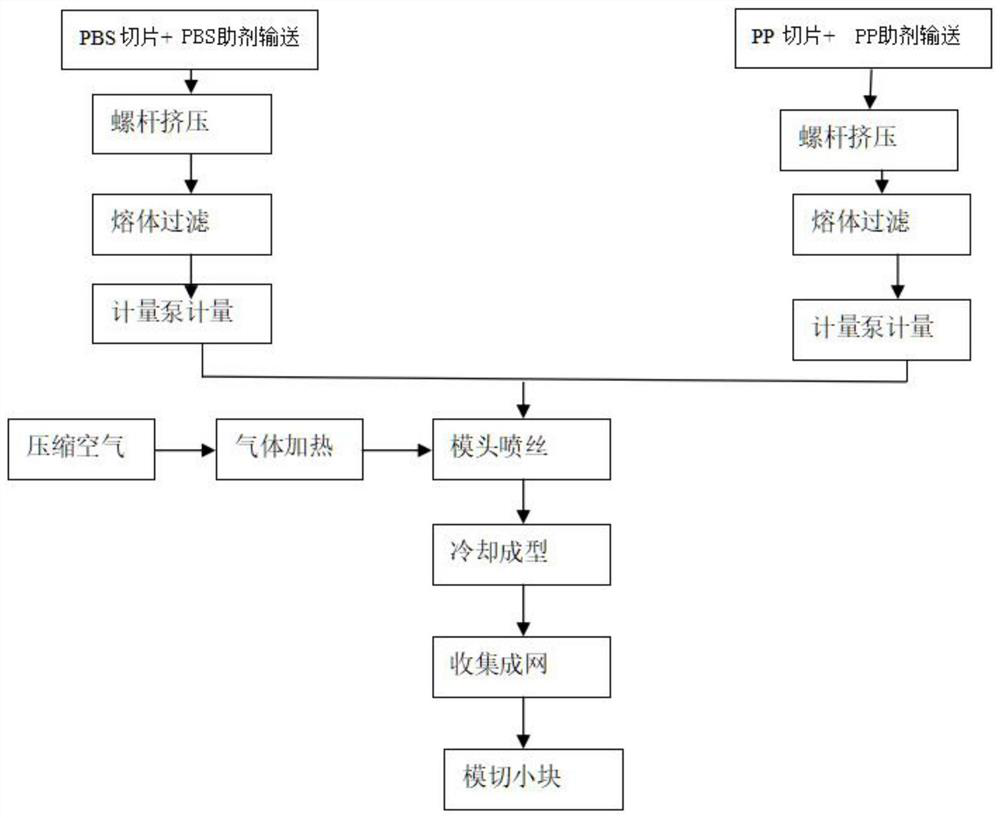

[0025] Such as figure 1 As shown, the process used in the manufacturing method of PBS / PP two-component melt-blown fiber filter material is:

[0026] Preparation of PBS melt: Dry the PBS raw material at 100°C for 2 hours, then mix the PBS raw material and PBS additive according to the mass percentage of 96.8:3.2, and then input it into a screw extruder with corresponding settings, and heat it at 190°C Melting down to obtain PBS melt, the PBS melt is filtered through the corresponding melt filter, and then metered by the corresponding metering pump;

[0027] Preparation of PP melt: Mix PP raw materials and PP additives according to the mass percentage of 99.2:0.8, and then input them into a screw extruder with corresponding settings, and melt them at 270°C to obtain PP melt. The correspondingly set melt filter is used for filtering, and then the correspondingly set metering pump is used for metering;

[0028] The PBS melt and PP melt obtained above are mixed according to the m...

Embodiment 2

[0031] Such as figure 1 As shown, the process used in the manufacturing method of PBS / PP two-component melt-blown fiber filter material is:

[0032]Preparation of PBS melt: Dry the PBS raw material at 80°C for 3 hours, then mix the PBS raw material and PBS additive according to the mass percentage of 96:4, and then input it into a screw extruder with corresponding settings, and heat it at 220°C Melting down to obtain PBS melt, the PBS melt is filtered through the corresponding melt filter, and then metered by the corresponding metering pump;

[0033] Preparation of PP melt: Mix PP raw materials and PP additives according to the mass percentage of 99:1, and then input them into a correspondingly set screw extruder, and melt them at 250°C to obtain PP melt. The correspondingly set melt filter is used for filtering, and then the correspondingly set metering pump is used for metering;

[0034] The PBS melt obtained above is mixed with the PP melt according to the mass percentage...

Embodiment 3

[0037] Such as figure 1 As shown, the process used in the manufacturing method of PBS / PP two-component melt-blown fiber filter material is:

[0038] Preparation of PBS melt: Dry the PBS raw material at 85°C for 3 hours, then mix the PBS raw material and PBS additive according to the mass percentage of 96.5:3.5, and then input it into a screw extruder with corresponding settings, and heat it at 200°C Melting down to obtain PBS melt, the PBS melt is filtered through the corresponding melt filter, and then metered by the corresponding metering pump;

[0039] Preparation of PP melt: Mix PP raw materials and PP additives according to the mass percentage of 99:1, and then input them into a correspondingly set screw extruder, and melt them at 250°C to obtain PP melt. The correspondingly set melt filter is used for filtering, and then the correspondingly set metering pump is used for metering;

[0040] The PBS melt obtained above is mixed with the PP melt according to the mass perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com