Base plate device for full-automatic traveling mechanism for ridge bed

A traveling mechanism and traveling device technology are applied in the field of full-automatic traveling mechanism chassis devices for furrow beds, which can solve the problems of poor planting quality and reliability, low automation, low operating efficiency, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]In order to explain the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and drawings. Those skilled in the art should understand. The content specifically described below is illustrative rather than restrictive, and should not limit the scope of protection of the present invention.

[0041]In the present invention, for the convenience of description, the description of the relative positional relationship of each component is described in accordance with the layout of the accompanying drawings in the specification. For example, the positional relationship of up, down, front, back, left, and right is based on the specification. The layout direction of the drawings is determined.

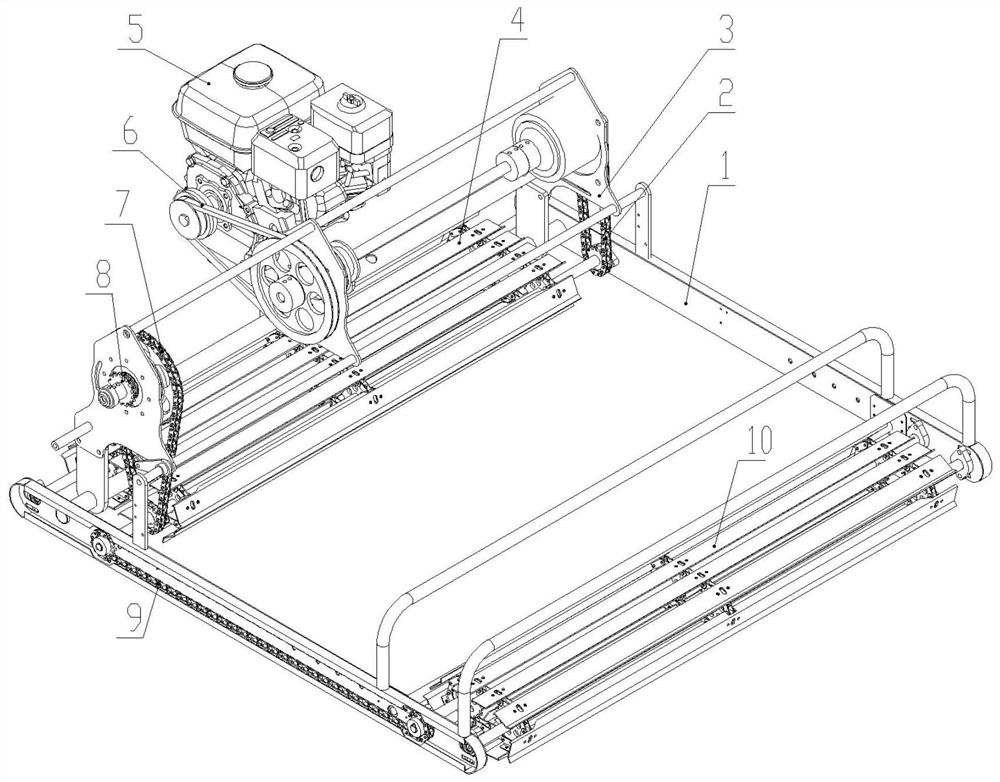

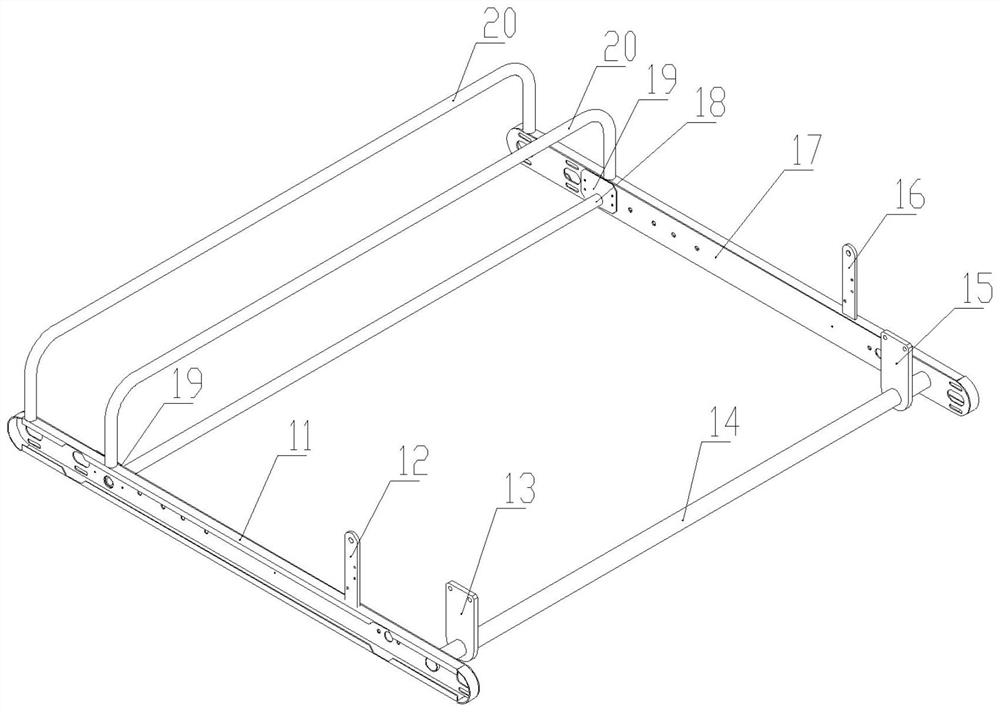

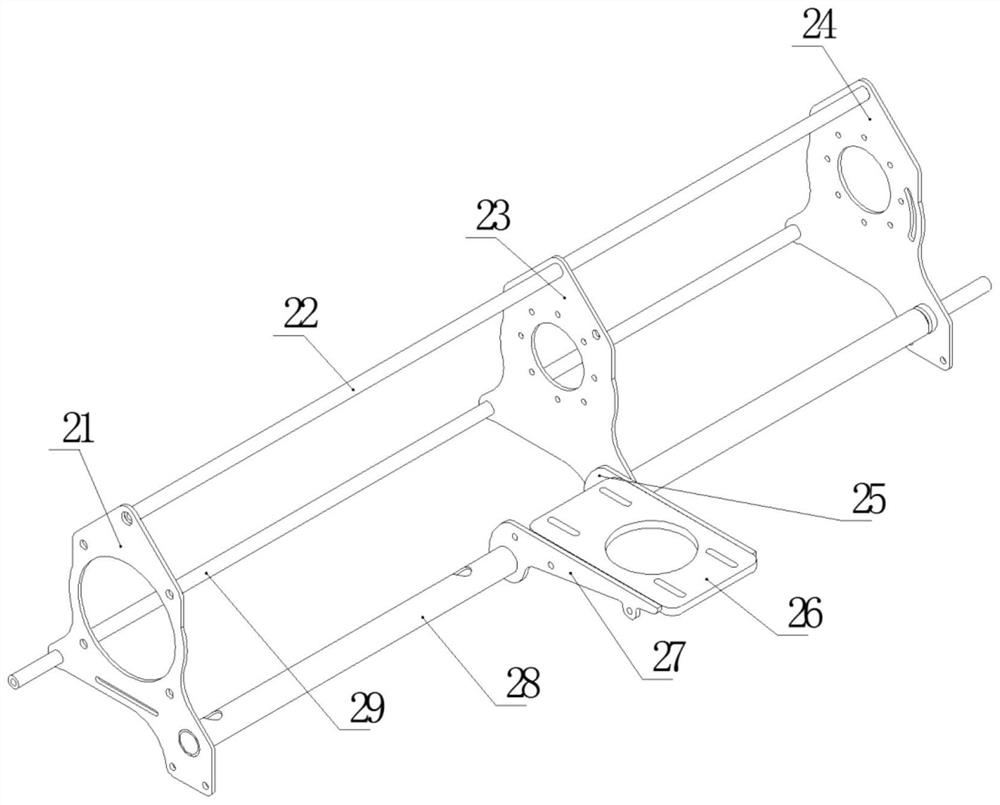

[0042]Such asFigure 1 to Figure 12As shown, a full-automatic walking mechanism chassis device for a border bed includes a chassis main support 1, a transmission chain Ⅰ2, a power combination bracket 3, an active walking device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com