Automatic condensation treatment auxiliary device for water-cooled electronic radiator

A technology of automatic processing and auxiliary devices, applied in the installation of electrical equipment casings/cabinets/drawers, electrical components, and support structures, etc., can solve problems such as labor consumption, equipment insulation degradation, short-circuit faults, and harsh working environment requirements. Effectiveness of workload, prevention of increase in air humidity, and prevention of short-circuit failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

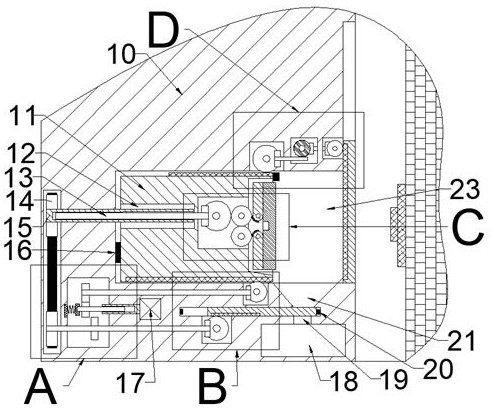

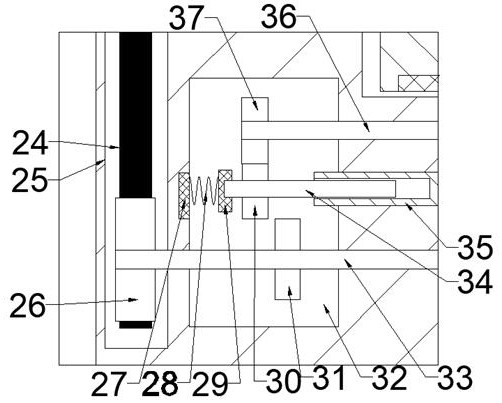

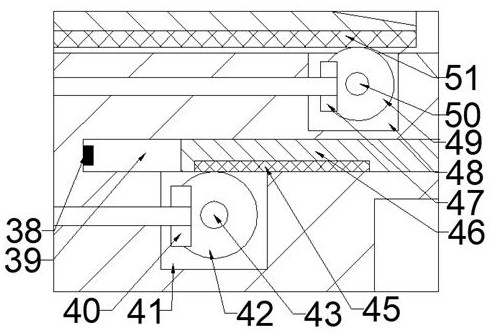

[0018] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019]A water-cooled electronic radiator automatic condensation treatment auxiliary device described in conjunction with accompanying drawings 1-5 includes an equipment box 10, a slide chamber 23 is provided inside the equipment box 10, and the front and rear ends of the slide chamber 23 are A sliding seat 11 is slidably connected between the walls, and a linkage rack 78 is fixedly connected to the upper surface of the sliding seat 11. A long shaft sleeve cavity 12 with an opening to the left is provided inside the sliding seat 11. The lower end of the sliding seat 11 A sliding gear 51 is fixedly connected to the end face, and an extrusion belt chamber 25 extending downward is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com