Optical communication semiconductor laser and aluminum-containing quantum well active layer butt joint growth method thereof

A quantum well active layer and growth method technology, which is applied in the field of optical communication semiconductor lasers, can solve problems such as reducing docking coupling efficiency, growing voids, increasing process complexity, etc., to avoid oxidation problems, improve performance, and improve docking coupling growth quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

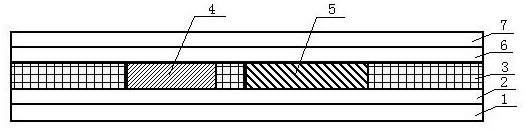

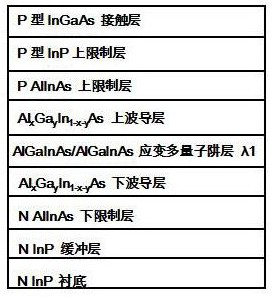

[0038] Such as Figure 1 to Figure 4 , an embodiment of the present invention provides a method for butt growth of an active layer containing an aluminum quantum well in an optical communication semiconductor laser, comprising the following steps:

[0039] S1) An N-type InP buffer layer 2 is grown on an N-type InP substrate 1, and then an InGaAsP aluminum-free passive waveguide layer 3, an InP confinement layer, and an InGaAs contact layer are sequentially grown on the N-type InP buffer layer to complete the first epitaxy , to obtain an epitaxial wafer with a structure such as figure 2 shown. In this embodiment, the thickness of the N-type InP buffer layer is 100-500 nm. The InGaAsP aluminum-free passive waveguide layer has a wavelength of 1.05um-1.4um and a thickness of 0.05-0.6um. The thickness of the InP confinement layer is 0.01-0.5um. The thickness of the InGaAs contact layer is 0.01-0.5um.

[0040] S2) Use the PECVD method to grow a SiO2 layer with a thickness of 0.0...

Embodiment 2

[0049] Such as Figure 1 to Figure 4 , this embodiment discloses an optical communication semiconductor laser, comprising a substrate, on which an aluminum-free passive waveguide layer and at least two aluminum-containing quantum well active layers are arranged side by side in the same horizontal plane, and each aluminum-containing quantum well has The source layers are butt-coupled with each other through the aluminum-free passive waveguide layer.

[0050] Further, a buffer layer is provided on the substrate, an aluminum-free passive waveguide layer and at least two aluminum-containing quantum well active layers are arranged on the buffer layer, and the aluminum-free passive waveguide layer and at least two aluminum-containing quantum well active layers are arranged on the buffer layer. An InP confinement layer and a contact layer are arranged on the layer, and the contact layer is located above the InP confinement layer.

[0051] Further, the aluminum-containing quantum wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com