Preparation method of Ga-Ti doped ZnO block thermoelectric material

A thermoelectric material and block technology, which is applied in the manufacture/processing of thermoelectric devices, and the material of the junction lead wires of thermoelectric devices. The effect of improving electrical and thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

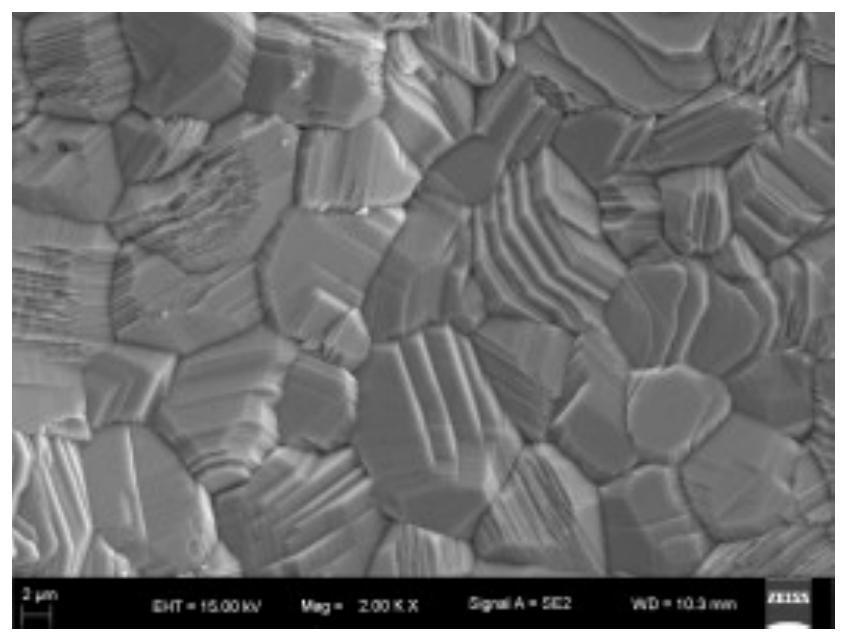

Image

Examples

Embodiment 1

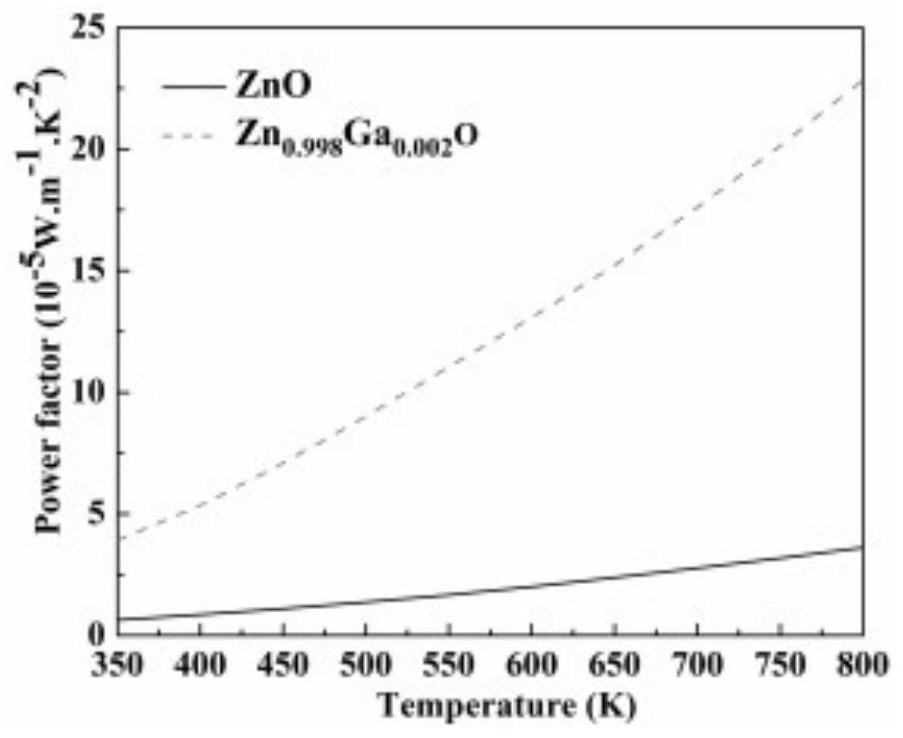

[0033] Step 1, according to the molecular formula Zn 0.998 Ga 0.002 O Weigh 9.978g of ZnO and 0.022g of Ga according to the ratio 2 o 3 Powder, utilizing ethanol to carry out wet ball milling, the mass ratio of ball to material is 5:1, and the ball milling time is 8h to obtain mixed powder;

[0034] Step 2, the mixed powder in step 1 is placed in 100 and 200 mesh sieves and sieved twice, and the powder between 100-200 mesh is taken and dried for later use;

[0035] Step 3, take the mixed powder in step 2, press the powder on a desktop press, the molding pressure is 5MPa, and the holding time is 30s; then further molding the green body in the vacuum system on the isostatic press, the molding pressure is 22MPa, The holding time is 5 minutes.

[0036] Step 4, sintering the green body formed in step 3 at 1200° C., holding the temperature for 10 minutes, and then cooling with the furnace to obtain a Ga-doped ZnO bulk thermoelectric material.

[0037] The density of the materia...

Embodiment 2

[0039] Step 1, according to the molecular formula Zn 0.998 Ti 0.002 O Weigh 9.942g of ZnO and 0.058g of TiO according to the ratio 2 Powder, utilizing ethanol to carry out wet ball milling, the mass ratio of ball to material is 5:1, and the ball milling time is 8h to obtain mixed powder;

[0040] Step 2, the mixed powder in step 1 is placed in 100 and 200 mesh sieves and sieved twice, and the powder between 100-200 mesh is taken and dried for later use;

[0041] Step 3, take the mixed powder in step 2, press the powder on a desktop press, the molding pressure is 5MPa, and the holding time is 30s; then further molding the green body in the vacuum system on the isostatic press, the molding pressure is 22MPa, The holding time is 5 minutes.

[0042] Step 4, sintering the green body formed in step 3 at 1200° C. for 10 h, and then cooling in the furnace to obtain a Ti-doped ZnO bulk thermoelectric material.

[0043] The density of the material obtained in Example 2 is 98.55%, an...

Embodiment 3

[0045] Step 1, according to the molecular formula Zn 0.99 Ti 0.01 O Weigh 9.893g of ZnO and 0.107g of TiO according to the ratio 2 Powder, utilizing ethanol to carry out wet ball milling, the mass ratio of ball to material is 5:1, and the ball milling time is 8h to obtain mixed powder;

[0046] Step 2, the mixed powder in step 1 is placed in 100 and 200 mesh sieves and sieved twice, and the powder between 100-200 mesh is taken and dried for later use;

[0047] Step 3, take the mixed powder in step 2, press the powder on a desktop press, the molding pressure is 5MPa, and the holding time is 30s; then further molding the green body in the vacuum system on the isostatic press, the molding pressure is 22MPa, The holding time is 5 minutes.

[0048] Step 4, sintering the green body formed in step 3 at 1200° C. for 10 h, and then cooling in the furnace to obtain a Ga-Ti doped ZnO bulk thermoelectric material.

[0049] The density of the material obtained in Example 3 is 99.16%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com