A High-Order Back-Wave Oscillation Suppression Structure for Ribbon-Traveling-Wave Tubes

A wave tube and high-order technology, applied in the field of high-order return-wave oscillation suppression structures, can solve the problems of increasing the design difficulty of electronic transmission systems, unfavorable development of miniaturized millimeter-wave devices, and increasing the size of slow-wave structures. effect, reduce stress, and avoid sharp declines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is further described:

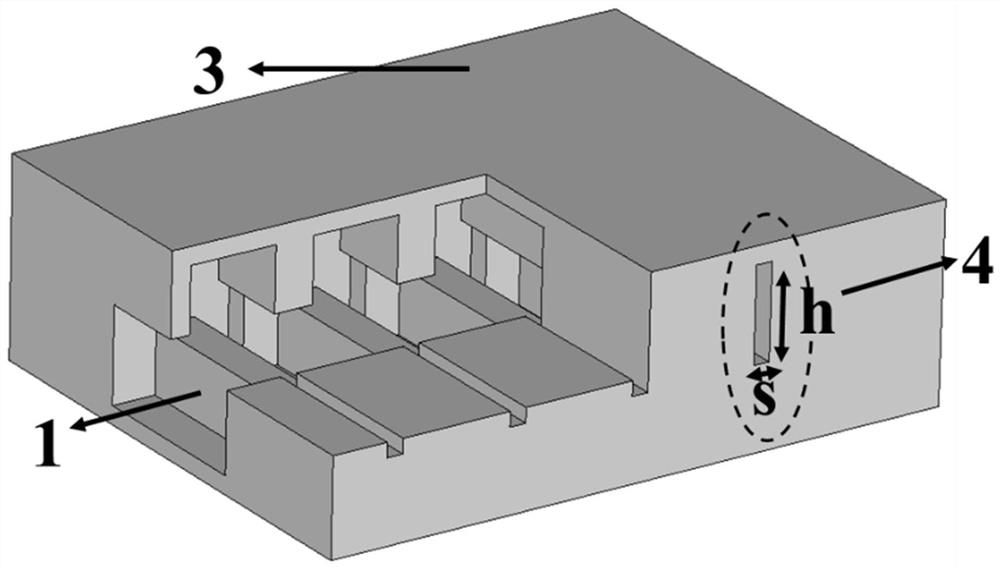

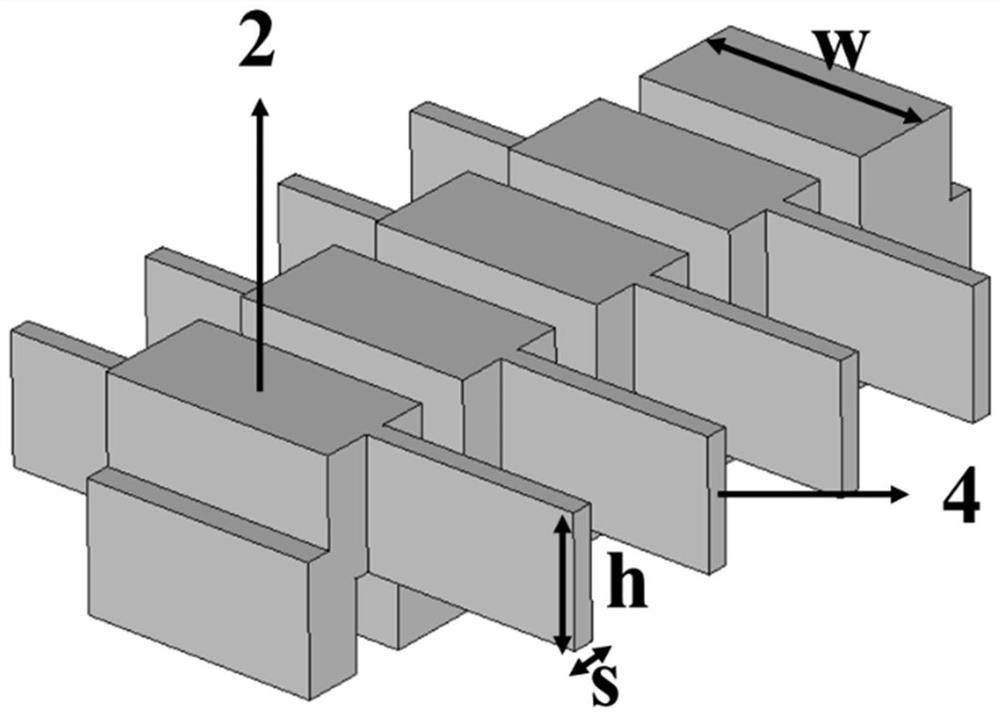

[0022] Refer to attached figure 2 , 3 , the present invention proposes a high-order back-wave oscillation suppression structure for a strip-shaped injection traveling wave tube. By loading interlaced rectangular coupling waveguides on both sides of the interlaced double-grid slow-wave structure, the structure realizes the suppression and absorption of high-order modes at the same time without destroying the working mode, effectively solving the problem of the strip injection traveling wave tube. Higher-order echo oscillations in the design.

[0023] The following is an example of a G-band strip traveling wave tube with a center frequency of 220GHz:

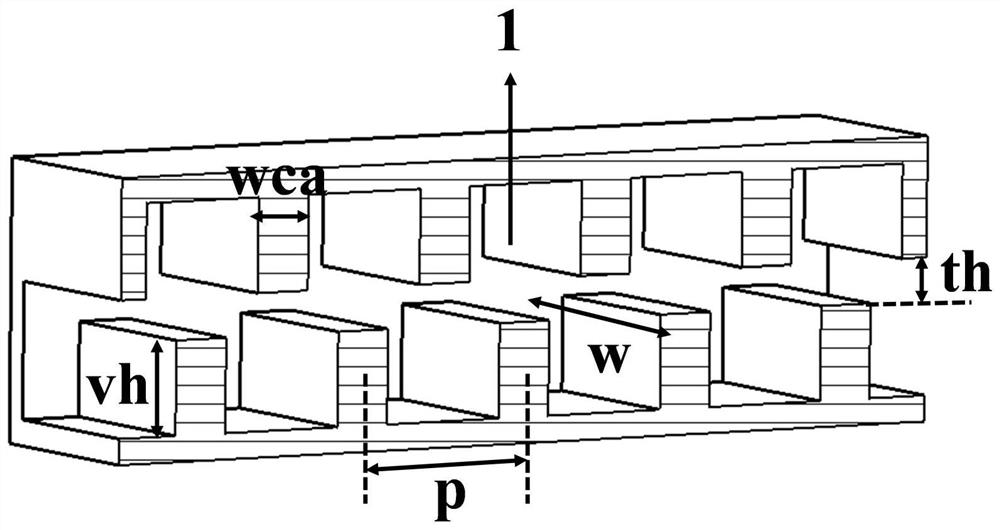

[0024] Such as figure 1 Shown is an interlaced double-grid slow-wave structure, metal grid height vh=0.33mm, grid width wca=0.2mm, grid length w=0.9mm, electron channel height th=0.15mm, period p=0.65mm. The interaction area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com