Method for testing corrosion resistance of metal coating

A metal coating and testing method technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of limited reference value of test results, difficulty in completely reproducing complex corrosion environments, and inability to manufacture, etc. Achieve the effect of high reliability of test results, real test environment and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the invention will be described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0026] The anti-corrosion performance test method of metal coating according to the embodiment of the present invention comprises the following steps:

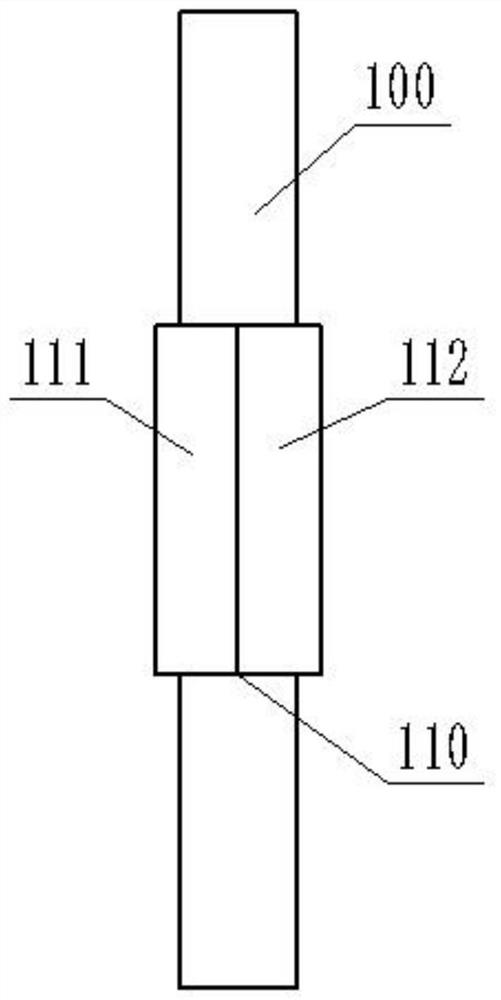

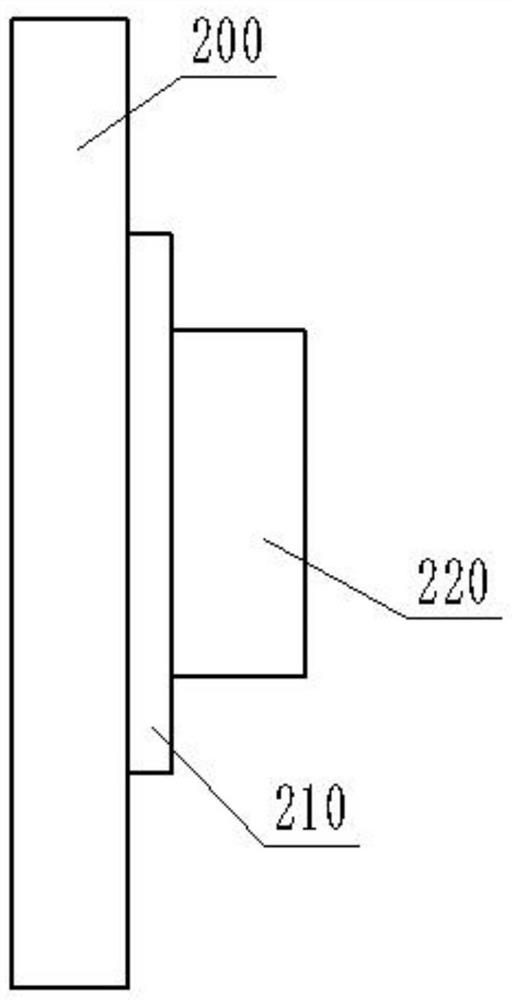

[0027] A) When the waste incineration waste heat boiler is shut down, install the test piece with metal coating on the pipe of the superheater of the waste incineration waste heat boiler;

[0028] B) Run the waste incineration waste heat boiler so that the flue gas produced by the waste incineration waste heat boiler can scour and corrode the test piece;

[0029] C) When the waste incineration waste heat boiler is shut down again, take out the test piece and analyze the anti-corrosion performance of the test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com