Construction process of reusable overhanging type steel fixing bolt and protecting sleeve

A technology for fixing bolts and protective sleeves, which is applied to the accessories of scaffolding, scaffolding supported by house structures, and house structure supports, etc. It can solve the problems of round steel waste and other problems, and achieve the effect of solving the difficulty of fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

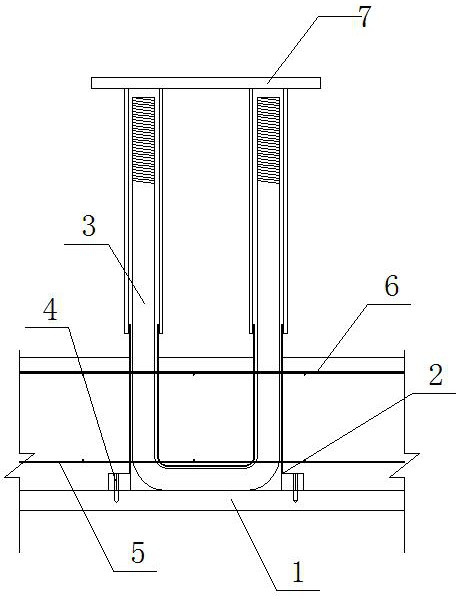

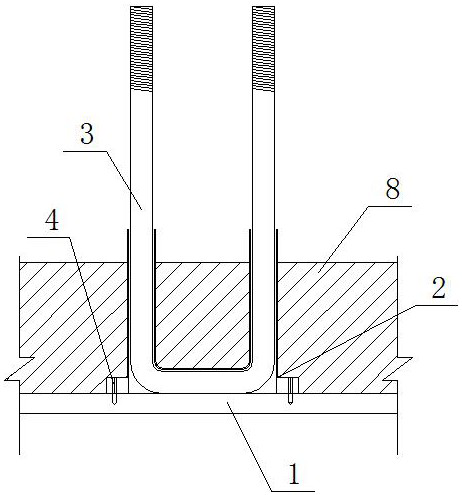

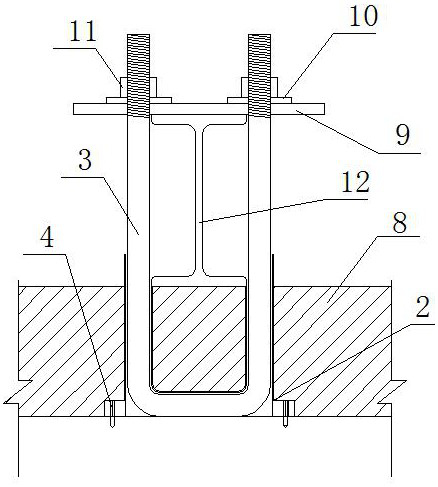

[0020] Such as Figure 1-3 As shown, a construction technique of a cantilever-shaped steel fixing bolt and a protective cover that can be used repeatedly includes the following steps:

[0021] Step 1: Complete the laying of the beam-slab bottom formwork 1 according to the construction method of the reinforced concrete beam-slab 8 structure, mark the position of the U-bolt 3 on the beam-slab bottom formwork 1 according to the scaffolding design plan, and place the customized U-shaped The bolt 3 is inserted into the prefabricated installation base 2, and the plane of the installation base 2 is closely connected with the upper surface of the beam plate bottom formwork 1, and the iron nail 4 is smashed into the hole on the ear plate of the prefabricated installation base 2 to fix the installation base 2;

[0022] Step 2: According to the construction method of the reinforced concrete beam slab 8 structure, the binding of the upper reinforcement mesh 6 and the lower reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com