Fuel injector fixing structure

A fixed structure and fuel injector technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve problems such as the difficulty of fixing the fuel injector and reduce the weight of the cylinder head, and achieve weight reduction, high adaptability, and easy installation Solid and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

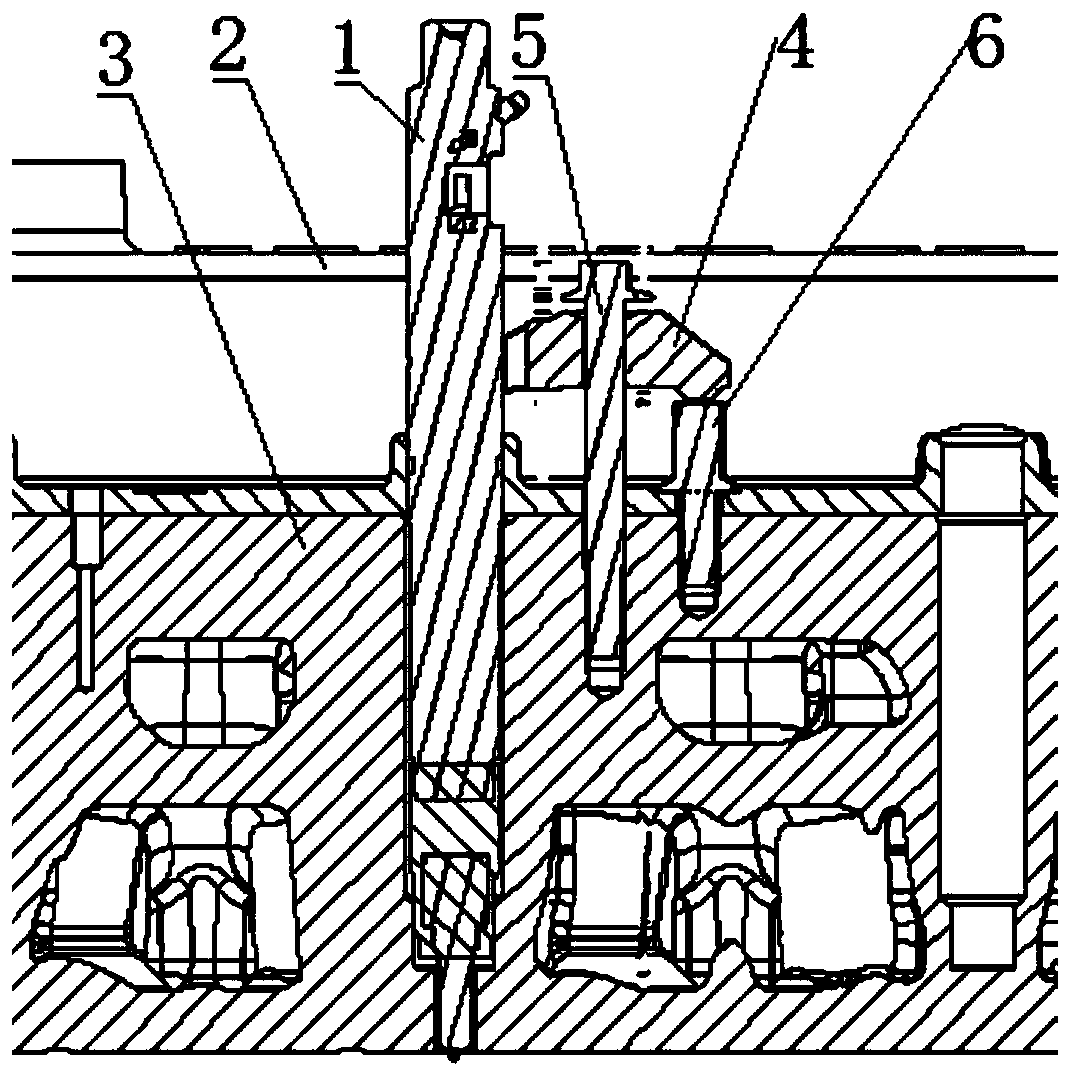

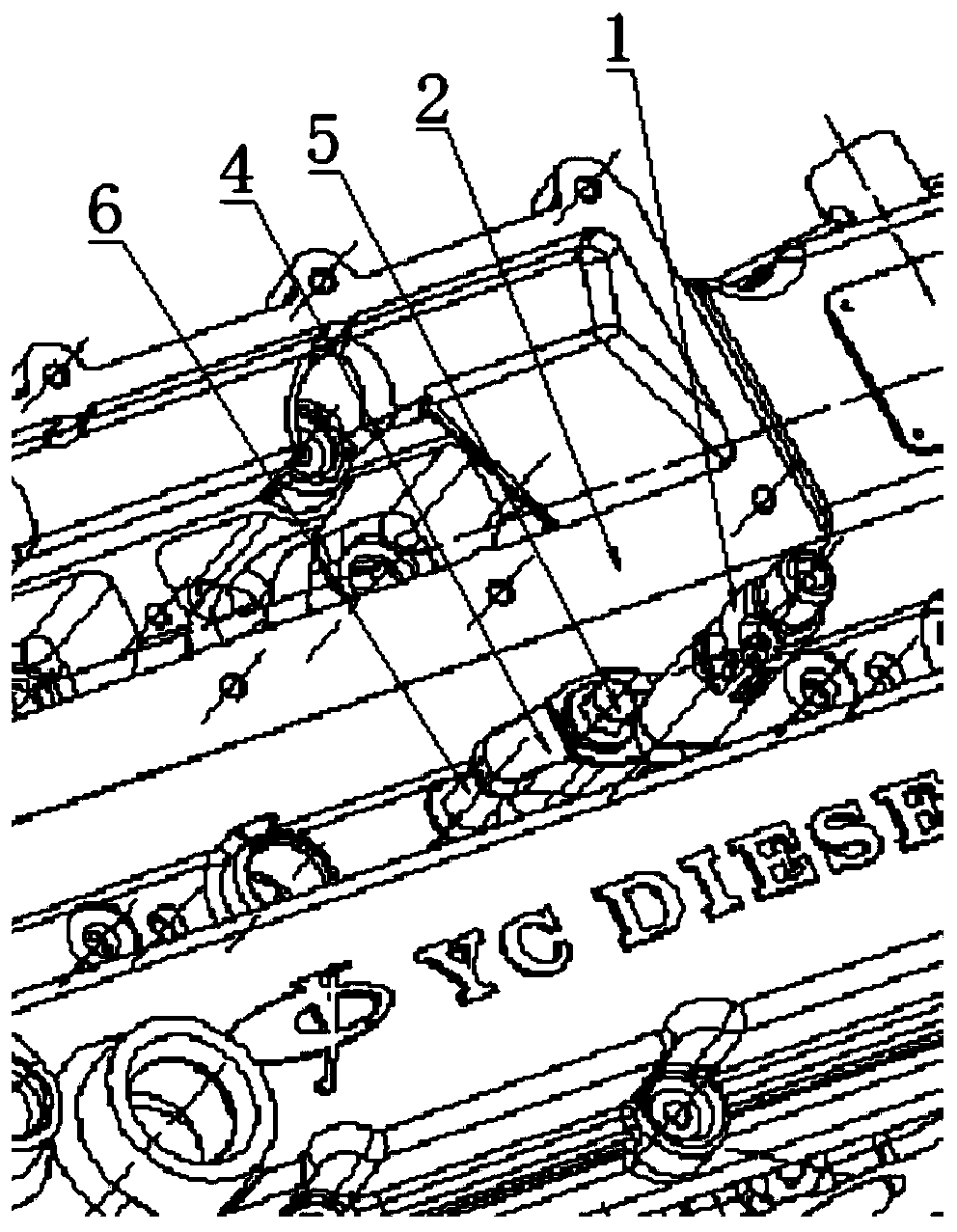

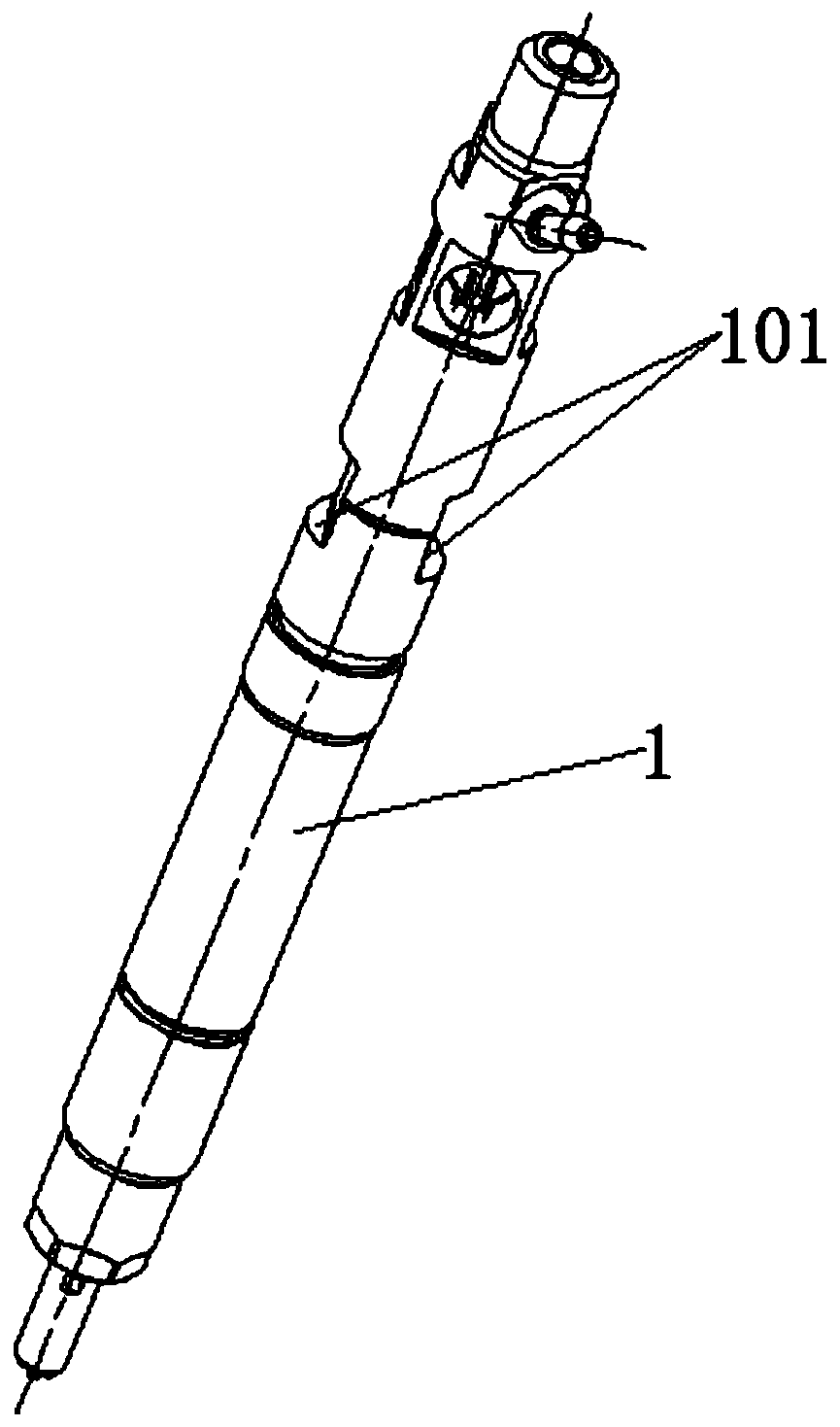

[0020] Such as figure 1 with figure 2 As shown, this embodiment is used to install the fuel injector 1 on the cylinder head 3, including a pressure block 4 with one end abutting against the mounting surface 101 on the fuel injector 1, and one end abutting against the middle of the pressure block 4 The compression bolt 5 on the surface and the other end threaded with the cylinder head 3 also includes a support element 6 threaded with the cylinder head 3 , the top of the support element 6 abuts against the bottom of the other end of the pressure block 4 .

[0021] This embodiment adopts the design structure of padding the high-pressure block 4, that is, the top of the support element 6 is used as a supporting surface to pad the high-pressure block 4, which avoids the direct installation of the pressure block 4 on the cylinder head 3 in the prior art, and the installation is firm and stable. to fix the cylinder head cover 2; at the same time, it can reduce the height of the cyl...

Embodiment 2

[0023] Such as figure 1 with figure 2 As shown, this embodiment is applied to an engine with a camshaft double overhead structure. When the cylinder head cover 2 of this model is arranged, there will be a situation that the two sides are high and the middle is low, and the middle low part is the installation part of the fuel injector 1. , this embodiment is used to install the fuel injector 1 on the cylinder head 3, including a pressure block 4 with one end abutting against the mounting surface 101 on the fuel injector 1, one end abutting against the middle upper surface of the pressure block 4 and The other end is connected with the compression bolt 5 of the cylinder head 3, that is, the middle part of the pressure block 4 has a through hole, and the threaded part of the compression bolt 5 passes through the through hole and is connected with the cylinder head 3; The support element 6 is threadedly connected to the cover 3 , and the top of the support element 6 abuts agains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com