Organic waste negative-pressure aerobic fermentation fertilizer preparation process

An organic waste and aerobic fermentation technology, applied in the field of organic fertilizers, can solve the problems of long treatment period, poor workshop sanitation, and difficulty in centralized collection and treatment of odors, so as to reduce processing difficulty and energy consumption, and achieve efficient collection and energy saving. , The effect of environmental control is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

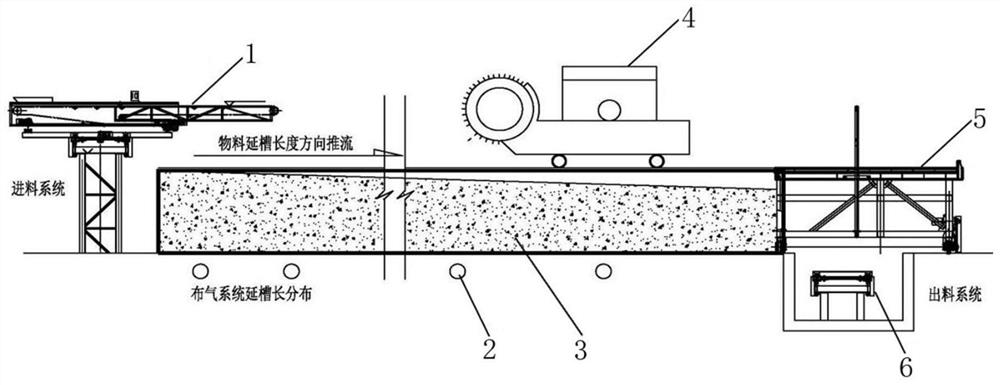

[0019] Such as figure 1 As shown, the process flow of organic waste negative pressure aerobic fermentation fertilizer process is as follows:

[0020] 1. Raw material supply and distribution. Three raw material bins are set up in the raw material supply and distribution workshop, which are organic waste material bin, auxiliary material bin, return bin and a set of bacterial agent adding equipment. During production, comprehensively consider the index requirements of mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com