Box for garbage truck

A technology for garbage trucks and boxes, which is applied to the box body for transporting wet garbage and the box body of garbage trucks, can solve the problems of secondary pollution, dripping, good safety, etc., to ensure effectiveness, increase safety, and application. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

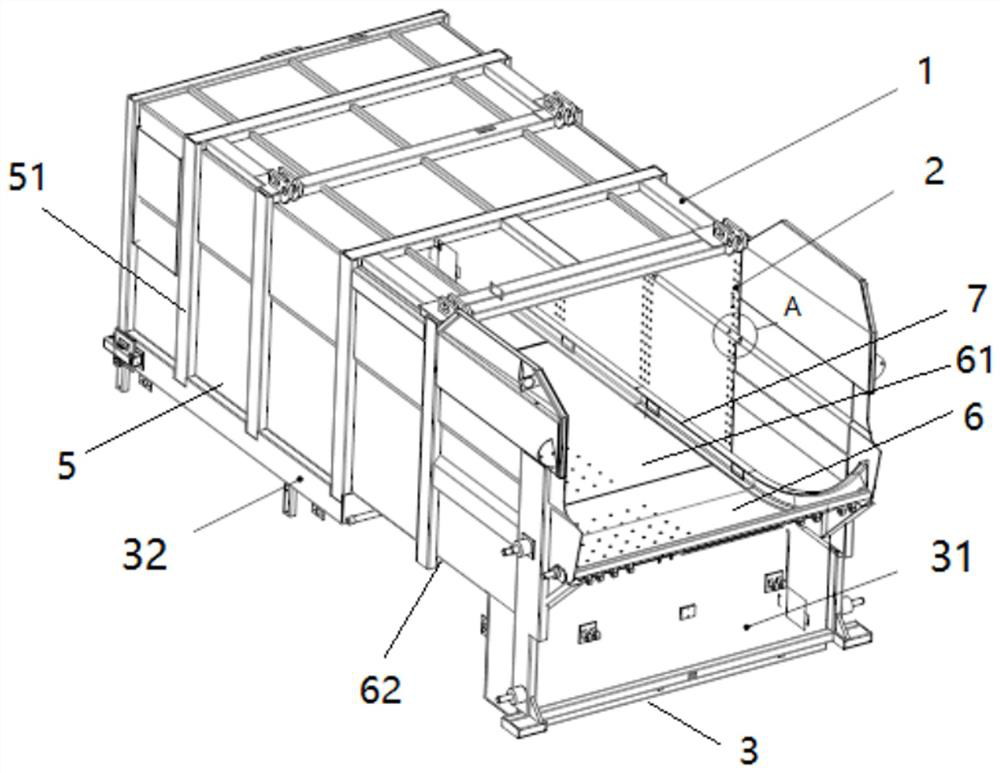

[0030] The box-type main body of the present invention is composed of an outer frame, a top plate connected with the outer frame, a bottom plate and surrounding panels. Specifically, the hoarding is made of wear-resistant and corrosion-resistant plates through welding, and the outer frame is made of bent steel plates, and then the hoarding and the frame are connected together by welding. A diversion hole is opened on the bottom plate of the main body to communicate with the sewage tank.

[0031] Further, a local arc-shaped structure can be arranged on the bottom plate here, and a sewage tank is arranged under the arc-shaped structure, so as to facilitate further rapid flow of water into the sewage tank.

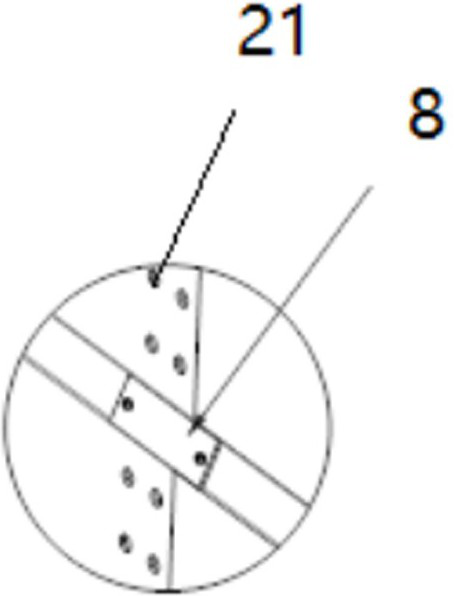

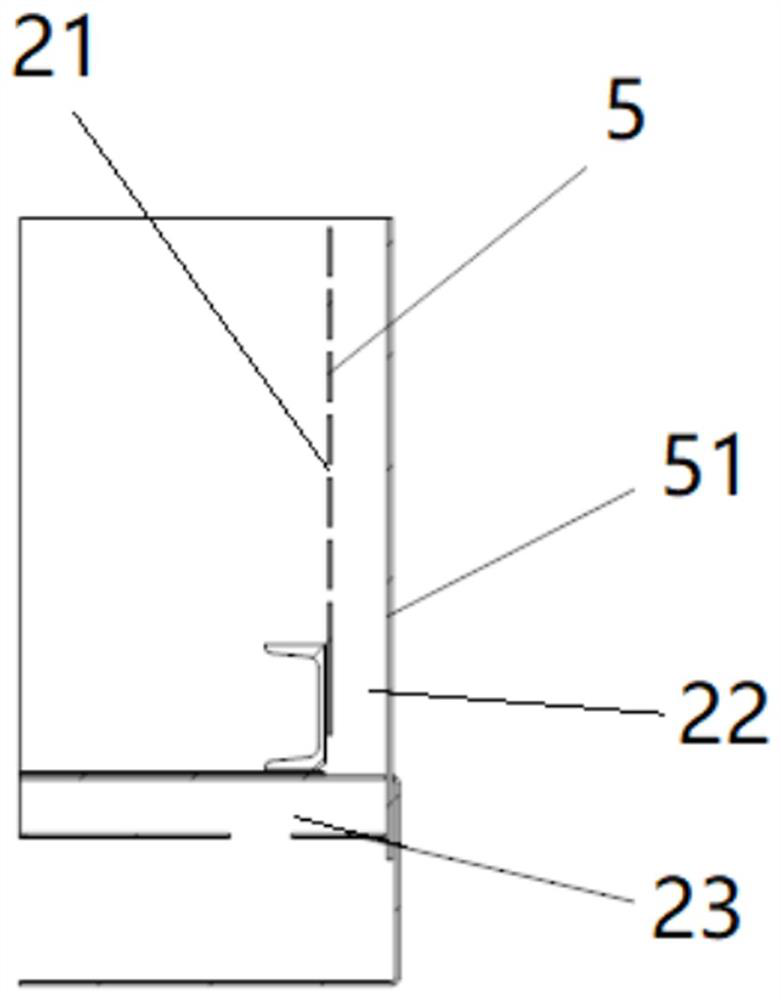

[0032] The inner wall of the coaming of the box-type main body is provided with several groups of drainage structures. Each drainage structure includes a diversion groove and a diversion pipe arranged at the bottom of the diversion groove. Adjacent diversion grooves are arran...

Embodiment 2

[0038] The present invention is made up of top plate 1, drainage structure 2, sewage tank 3, coaming plate 5, bottom plate 6, chute 7 and rubbish cleaning cover 8.

[0039] Above-mentioned top plate part 1 is made up of steel plate and square pipe, and plays auxiliary role with the present invention; Coaming plate comprises back plate, left side coaming plate and right side coaming plate, wherein left and right side coaming plates are arranged symmetrically, the material of rear plate It is made by bending corrosion-resistant and wear-resistant steel plate.

[0040] The outsides of the left and right enclosures are provided with side columns, and the side columns 51 are formed by bending steel plates. The material is high-quality carbon steel plate with a thickness of 2-6mm; the shape is U-shaped, the width is 50-200mm, and the height is 50-100mm; the number of side columns is 6-16.

[0041]The material of the above-mentioned hoarding plate is a wear-resistant and corrosion-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com