Preparation method of sturgeon freeze-dried powder and sturgeon freeze-dried powder

A technology of freeze-dried powder and sturgeon, which is applied in the preparation of freeze-dried sturgeon powder and the field of freeze-dried sturgeon powder, which can solve the problems of loss of nutrients and active ingredients, less research on enzymatic hydrolysis and fermentation, and low absorption and utilization rate, etc. problems, to achieve the effect of promoting brain development, enhancing human immunity, and easy preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

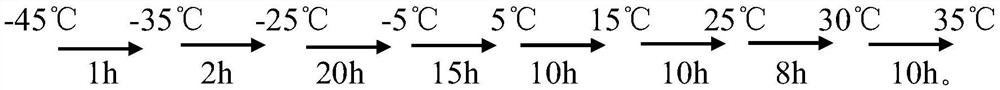

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of sturgeon freeze-dried powder, comprising:

[0029] (1) mixing the sturgeon meat slurry with the fish cartilage slurry to obtain the sturgeon meat cartilage slurry, enzymolyzing the sturgeon meat cartilage slurry, inactivating the enzyme, and filtering to obtain the sturgeon enzymatic hydrolysis filtrate;

[0030] The enzymatic hydrolysis method comprises: enzymolyzing the sturgeon meat cartilage slurry sequentially with Bacillus subtilisin neutral protease and papain;

[0031] (2) Mixing the sturgeon skin slurry, the sturgeon head slurry and the sturgeon tail slurry to obtain the sturgeon skin head and tail slurry, mixing the sturgeon skin head and tail slurry with a nitrogen source and a carbon source, and fermenting, Obtain the sturgeon fermentation liquid, filter the sturgeon fermentation liquid to obtain the sturgeon fermentation filtrate;

[0032] The microorganisms used in the fermentation include Streptococcus therm...

Embodiment 1

[0058] (1) Cut 80kg of sturgeon meat into blocks, pulverize, add 10kg of water and grind to obtain a sturgeon meat slurry, pulverize 4kg of sturgeon cartilage, add 2kg of water and grind to obtain a sturgeon cartilage slurry, mix the sturgeon meat slurry with fish Mix the cartilage slurry, add 30 kg of water to obtain a sturgeon cartilage slurry with a fineness of 3 μm, add Bacillus subtilisin neutral protease with a quality of 4‰ of the sturgeon cartilage slurry, and enzymolyze it for 3 hours at a pH value of 7 and a temperature of 55°C. Then add papain with a quality of 2.5‰ of sturgeon meat cartilage slurry, enzymolyze it for 3 hours at a pH value of 7 and a temperature of 50°C, inactivate the enzyme at a temperature of 93°C for 20 minutes, and pass through a 100-mesh sieve to obtain sturgeon Enzyme filtrate.

[0059] (2) Grind 2kg of sturgeon skin, add 1kg of water and grind to obtain a sturgeon skin slurry, pulverize 8kg of sturgeon head, add 4kg of water and grind to obt...

Embodiment 2

[0066] (1) Cut 70kg of sturgeon meat into blocks, pulverize it, add 9kg of water and grind it finely to obtain a sturgeon meat slurry, pulverize 3 kg of sturgeon cartilage, add 1 kg of water and grind it finely to obtain a sturgeon cartilage slurry, mix the sturgeon meat slurry with fish Mix the cartilage slurry, add 25 kg of water to obtain a sturgeon cartilage slurry with a fineness of 5 μm, add Bacillus subtilisin neutral protease with a quality of 2‰ of the sturgeon cartilage slurry, and enzymolyze it for 4 hours at a pH value of 6 and a temperature of 45°C. Then add papain of 1.5‰ of sturgeon meat cartilage slurry, enzymatically hydrolyze for 4 hours under the conditions of pH value 6 and temperature 45°C, inactivate the enzyme at 90°C for 30 minutes, and pass through an 80-mesh sieve to obtain sturgeon enzyme solution filtrate.

[0067] (2) Pulverize 1kg of sturgeon skin, add 0.5kg of water and grind to obtain a sturgeon skin slurry, pulverize 7kg of sturgeon head, add 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com