Processing method of storable and easy-to-cook whole grains and/or mixed beans

A processing method and whole grain technology, applied in the processing field of whole grains and/or miscellaneous beans, can solve the problems of shortened shelf life, incomplete gelatinization, and difficulty in gelatinization, etc. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

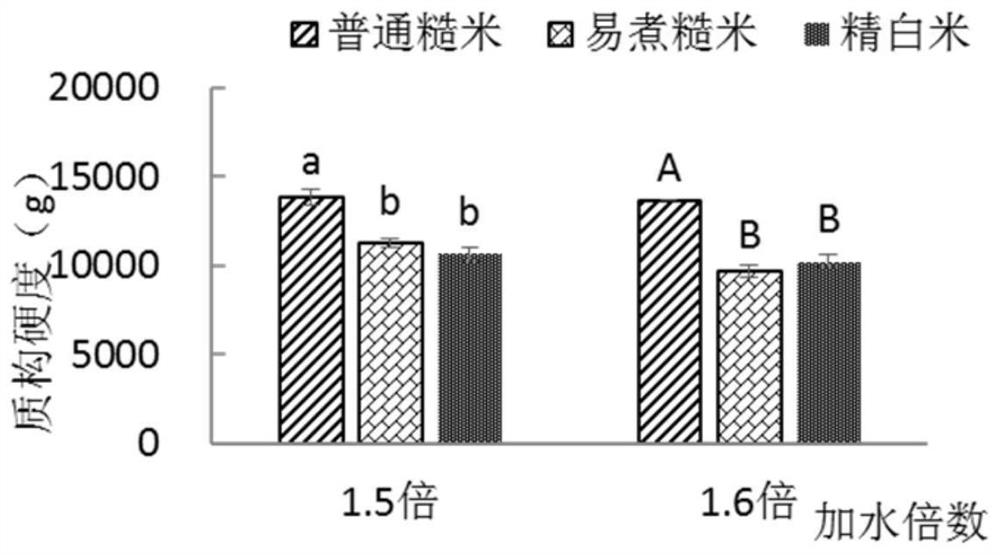

Image

Examples

Embodiment 1

[0047] A kind of processing method of easy-to-boil whole grain brown rice, using brown rice as processing raw material, comprises the steps:

[0048] 1) Cleaning: 1 part by mass of the raw material is subjected to impurity removal, color sorting, and grain sorting to obtain brown rice raw material with uniform color and grain shape.

[0049] 2) Raw material pretreatment: Pour the cleaned brown rice into an airtight container, evenly spray water accounting for 20% of the weight of the raw material, stir evenly, and then seal and stand for 6 hours to obtain brown rice with a water content of 26%.

[0050] 3) Steam explosion aging: put the whole grain rice after water adjustment in a steam explosion reactor, use saturated steam with a temperature of 140°C and a pressure of 0.26MPa for steam explosion treatment, and hold the pressure for 180s to obtain steam explosion After the whole grain brown rice.

[0051] 4) Dispersion, drying and cooling: dry the steam-exploded whole grains...

Embodiment 2

[0060] A processing method for storage-resistant and easy-to-cook whole-grain adzuki beans, using adzuki beans as a processing raw material, comprising the steps of:

[0061] 1) Cleaning: 1 part by mass of the raw material is subjected to impurity removal, color sorting, and grain sorting to obtain adzuki bean raw material with uniform color and grain shape.

[0062] 2) Raw material pretreatment: Pour the cleaned red bean into an airtight container, evenly spray fiber softening solution accounting for 25% of the raw material weight, stir evenly and let it stand for 16 hours to obtain whole-grain red bean with a water content of 28%.

[0063] 3) Steam explosion aging: put the water-adjusted red beans in a steam explosion reactor, and use saturated steam with a temperature of 170°C and a pressure of 0.69MPa for steam explosion treatment. The pressure holding time is 120s, and the obtained steam explosion of whole grain red adzuki beans.

[0064] 4) Dispersion, drying and coolin...

Embodiment 3

[0073] A storage-resistant and easy-to-cook whole-grain mung bean processing method uses mung beans as a processing raw material, comprising the steps of:

[0074] 1) Cleaning: 1 mass part of the raw material is subjected to impurity removal, color sorting, and grain sorting to obtain mung bean raw materials with uniform color and grain shape.

[0075] 2) Raw material pretreatment: Pour the cleaned red bean into an airtight container, evenly spray water accounting for 15% of the raw material weight, stir evenly and let stand for 10 hours to obtain whole-grain mung beans with a water content of 23%.

[0076] 3) Steam explosion ripening: put the water-adjusted mung beans in a steam explosion reactor, use saturated steam with a temperature of 160°C and a pressure of 0.52MPa for steam explosion treatment, and hold the pressure for 60s to obtain the steam-exploded mung beans. Whole grain mung beans.

[0077] 4) Dispersion, drying and cooling: dry the steam-exploded whole grains in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com