A waveguide method microwave dielectric material ultra-low temperature complex electromagnetic parameter testing device

A technology of microwave dielectric materials and electromagnetic parameters, which is applied in the direction of measuring devices, magnetic performance measurement, magnetic measurement environment, etc., can solve the problems of insufficient development, etc., and achieve the effect of good conductivity and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

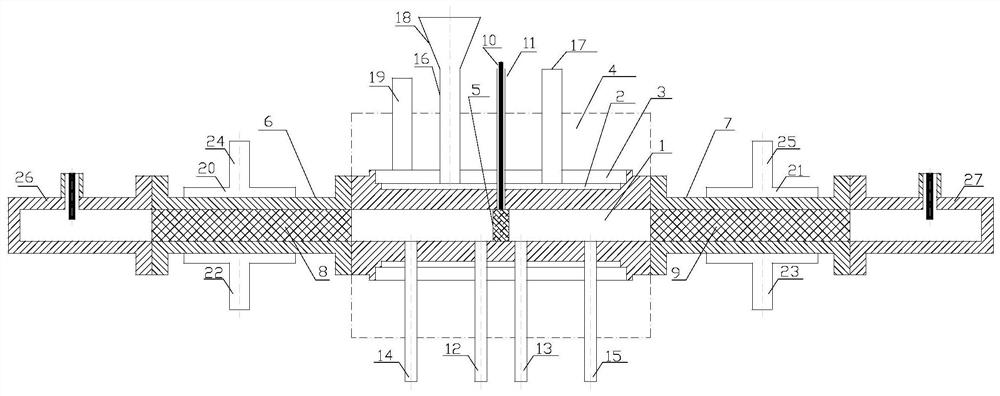

[0031] Such as figure 1 As shown, a waveguide method microwave dielectric material ultra-low temperature complex electromagnetic parameter testing device according to the present invention is designed by using the rectangular waveguide method test principle. A vacuum heat insulation chamber [3] is set around the outside of the nitrogen refrigeration chamber [2], and an insulation layer [4] of a certain thickness is arranged outside the vacuum insulation chamber [3]. The insulation layer [4] can be in any shape according to actual needs. The test section waveguide [1] has a rectangular cross-section inner cavity at the center and rectangular flanges at both ends. The measured microwave dielectric material [5] that can transmit microwaves is placed in the middle of the test section waveguide [1] inner cavity, and Separate the cavity of the test section waveguide [1] from the middle, and the cross-sectional size of the microwave dielectric material [5] to be tested should be slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com