Production method of mulberry brandy

A production method and technology of brandy, applied in the field of wine making, can solve problems such as difficulties in long-distance transportation and storage and preservation, limited sales of fresh mulberries, juicy mulberries and easy to rot, and achieve soft taste, unique flavor and improved drug efficacy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

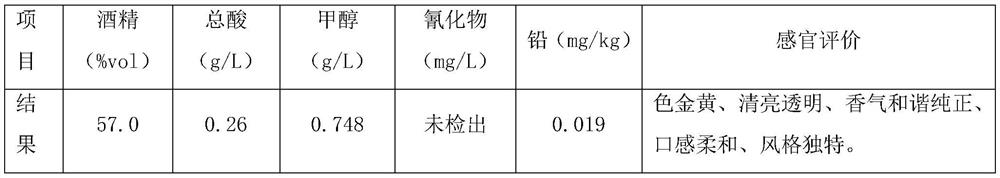

Embodiment 1

[0033] A kind of production method of mulberry brandy, comprises the following steps:

[0034] (1) Mulberry picking and sorting: select fresh purple-black skinned mulberries, pick them manually, and remove green fruits, diseased fruits and foreign objects.

[0035] (2) Beating: use a beater to beat the pulp and remove the stems to obtain mulberry pulp.

[0036] (3) Original wine brewing:

[0037] ① Raw material adjustment: add mulberry pulp to the fermenter, add pectinase 60mg / L, adjust the TSS content of pulp soluble solids to 22% with white sugar, and control the temperature at 22°C.

[0038] ②Fermentation cycle: 300mg / L yeast was activated at 10 times 39°C with 5% sugar water for 28 minutes. After the activation is completed, the wine is pumped into the fermenter and circulated in a closed loop for 30 minutes. After inoculation, continue to ferment at 22°C for 12 days under temperature control. During the fermentation process, the airtight circulation is performed twice...

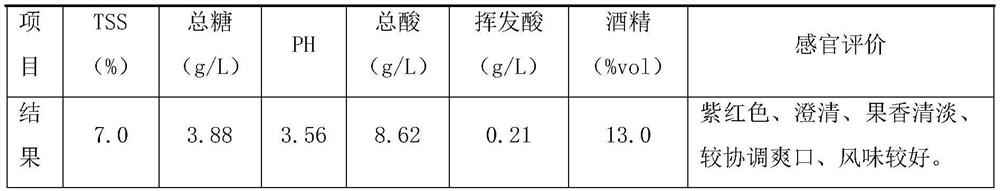

Embodiment 2

[0047] A kind of production method of mulberry brandy, comprises the following steps:

[0048] (1) Mulberry picking and sorting: select fresh purple-black skinned mulberries, pick them manually, and remove green fruits, diseased fruits and foreign objects.

[0049] (2) Beating: use a beater to beat the pulp and remove the stems to obtain mulberry pulp.

[0050] (3) Original wine brewing:

[0051] ① Adjustment of raw materials: Add mulberry pulp to a fermenter, add pectinase 60 mg / L, adjust the TSS content of pulp soluble solids to 22.5% with white sugar, and control the temperature at 20°C.

[0052] ②Fermentation cycle: 300mg / L yeast was activated in 10 times 39℃ 5% sugar water for 30min. After the activation is completed, the wine is pumped into the fermenter and circulated in a closed loop for 30 minutes. After inoculation, continue to ferment at 20°C for 13 days under temperature control. During the fermentation process, the airtight circulation is performed twice a day. ...

Embodiment 3

[0061] A kind of production method of mulberry brandy, comprises the following steps:

[0062] (1) Mulberry picking and sorting: select fresh purple-black skinned mulberries, pick them manually, and remove green fruits, diseased fruits and foreign objects.

[0063] (2) Beating: use a beater to beat the pulp and remove the stems to obtain mulberry pulp.

[0064] (3) Original wine brewing:

[0065] ①Raw material adjustment: Add mulberry pulp to the fermentation tank, add pectinase 60mg / L, adjust the TSS content of pulp soluble solids to 22.0% with white sugar, and control the temperature at 18°C.

[0066] ②Fermentation cycle: 300mg / L yeast was activated in 10 times 39℃ 5% sugar water for 30min. After the activation is completed, the wine is pumped into the fermenter and circulated in a closed loop for 30 minutes. After inoculation, continue to ferment at 18°C for 11 days under temperature control. During the fermentation process, the airtight circulation is performed twice...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com