Interior wall putty as well as preparation method and application thereof

A technology for interior wall putty and energy storage materials, applied in the direction of filling slurry, etc., can solve the problems of harmful volatile organic compounds, lack of temperature control and humidity control, lack of antibacterial and mildew resistance, etc., to improve sag resistance, Convenient construction method and the effect of improving construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

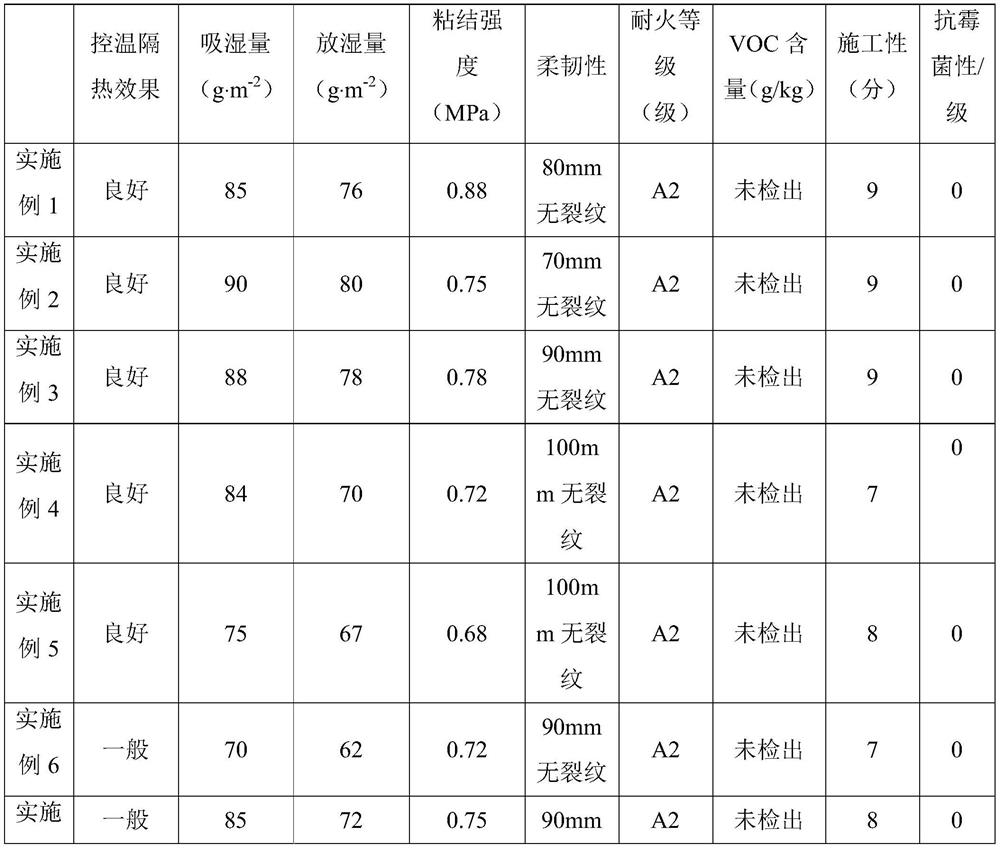

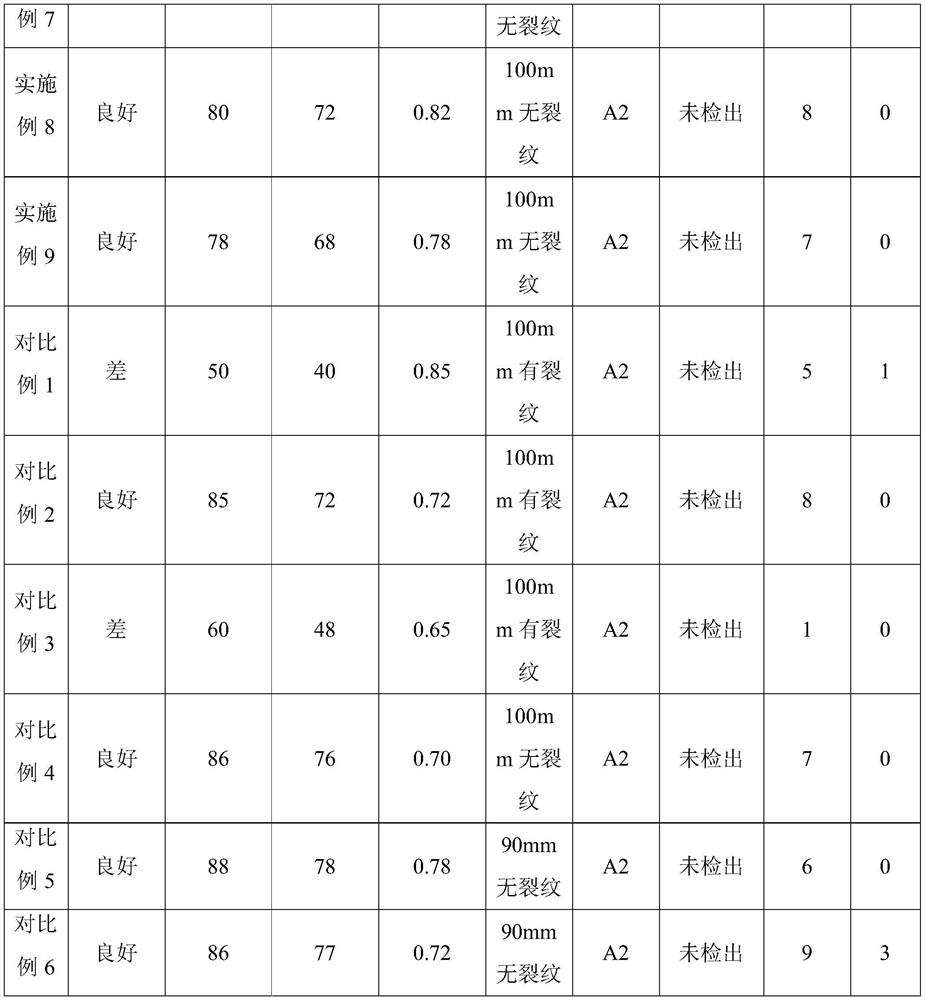

Examples

Embodiment 1

[0083]This embodiment provides an interior wall putty. The interior wall putty comprises 20 parts by weight of white cement (level 42.5, whiteness ≥88), 20 parts of composite phase change energy storage material (modified attapulgite), and quartz Sand powder (gradation: 80 mesh ~ 140 mesh 10%, 140 mesh ~ 180 mesh 30% and 180 ~ 220 mesh quartz sand powder 60%) 56.32 parts, WACKER 8034H rubber powder 2.5 parts, hydroxypropyl methyl fiber 0.4 part of plain ether (8000mPa·s), 0.5 part of white wood fiber (500μm), 0.2 part of aluminum magnesium silicate thixotropic lubricant, and 0.08 part of benzisothiazolinone anti-mold and fungicide. The preparation method includes the following steps:

[0084](1) Dry the attapulgite at 75°C for 26h, then add lauric acid to control the mass ratio of the attapulgite and lauric acid to 1.5:1, and mix to obtain a mixed powder; The powder was subjected to vacuum adsorption treatment for 10 hours; repeated 3 times, and then the mixed powder after vacuum adsor...

Embodiment 2

[0089]This embodiment provides an interior wall putty. The interior wall putty comprises 15 parts by weight of white cement (level 52.5, whiteness ≥88), 25 parts of composite phase change energy storage material (modified attapulgite), quartz Sand powder (gradation: 80 mesh ~ 140 mesh 15%, 140 mesh ~ 180 mesh 45% and 180 ~ 220 mesh quartz sand powder 40%) 55.35 parts, WACKER 8034H rubber powder 3 parts, hydroxypropyl methyl fiber 0.8 part of plain ether (5000mPa·s), 0.7 part of white wood fiber (500μm), 0.05 part of aluminum magnesium silicate thixotropic lubricant, and 0.1 part of benzisothiazolinone anti-mold and fungicide. The preparation method includes the following steps:

[0090](1) Dry the attapulgite at 85°C for 22h, then add paraffin, control the mass ratio of the attapulgite and paraffin to 3:1, and mix to obtain a mixed powder; Vacuum adsorption treatment for 6 hours; repeat 4 times, and then vacuum dry the mixed powder after vacuum adsorption treatment at 75°C and 0.06 Pa ...

Embodiment 3

[0095]This embodiment provides an interior wall putty. The interior wall putty comprises 25 parts by weight of white cement (level 52.5, whiteness ≥88), 22 parts of composite phase change energy storage material (modified attapulgite), quartz Sand powder (gradation: 80 mesh ~ 140 mesh 20%, 140 mesh ~ 180 mesh 40% and 180 ~ 220 mesh quartz sand powder 40%) 49.05 parts, WACKER 8034H rubber powder 2 parts, hydroxypropyl methyl fiber 0.8 part of plain ether (7000mPa·s), 1 part of white wood fiber (500μm), 0.1 part of aluminum magnesium silicate thixotropic lubricant, and 0.05 part of benzisothiazolinone anti-mold fungicide, the interior wall putty The preparation method includes the following steps:

[0096](1) Dry the attapulgite at 80°C for 24 hours, then add lauric acid to control the mass ratio of attapulgite and lauric acid to 1.5:1, and mix to obtain a mixed powder; The powder is subjected to vacuum adsorption treatment for 8 hours; repeated 3 times, and then the mixed powder after v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com