Split type forklift overhead guard

A roof guard, split-type technology, applied to the roof, vehicle parts, lifting devices, etc., to achieve the effect of improving convenience, convenient arrangement and storage, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

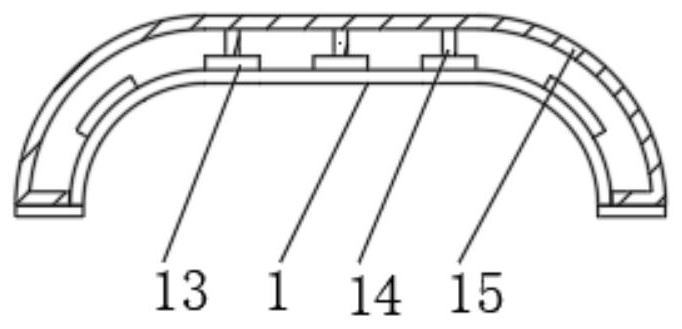

[0024] see Figure 1-2 , the present invention provides a technical solution: a split-type forklift roof guard, including an upper roof frame 1, the front side of the bottom of the upper roof frame 1 is fixedly connected with the tops of two groups of short slide bars 2, and the bottom of the upper roof frame 1 The rear sides of the two sets of long slide bars 3 are respectively fixedly connected to the tops, the outer side walls of the short slide bars 2 are slidably connected to the middle part of the slide seat 4, and the opposite sides of the two sets of slide seats 4 are provided with escape grooves 8. The avoidance groove 8 is passed through by the left side and the right side of the push plate 7 respectively, and the tops of the push plate 7 are in contact with the bottoms of the two groups of short slide rods 2 respectively, and the bottoms of the push plate 7 are respectively connected with the tops of the two groups of threaded rods 6 contact, the outer surfaces of t...

Embodiment 2

[0030] see Figure 2-4, the present invention provides a technical solution: a split-type forklift roof guard, including an upper roof frame 1, the front side of the bottom of the upper roof frame 1 is fixedly connected with the tops of two groups of short slide bars 2, and the bottom of the upper roof frame 1 The rear sides of the two sets of long slide bars 3 are respectively fixedly connected to the tops, the outer side walls of the short slide bars 2 are slidably connected to the middle part of the slide seat 4, and the opposite sides of the two sets of slide seats 4 are provided with escape grooves 8. The avoidance groove 8 is passed through by the left side and the right side of the push plate 7 respectively, and the tops of the push plate 7 are in contact with the bottoms of the two groups of short slide rods 2 respectively, and the bottoms of the push plate 7 are respectively connected with the tops of the two groups of threaded rods 6 contact, the outer surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com