Regular winding device for fire hose

A fire hose and winding device technology, which is applied in the directions of coiling strips, transportation and packaging, thin material handling, etc., can solve the problems of long length of fire hose, affecting work efficiency, and consuming a lot of physical strength, so as to reduce labor costs. Strength, improve work efficiency, not easy to wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

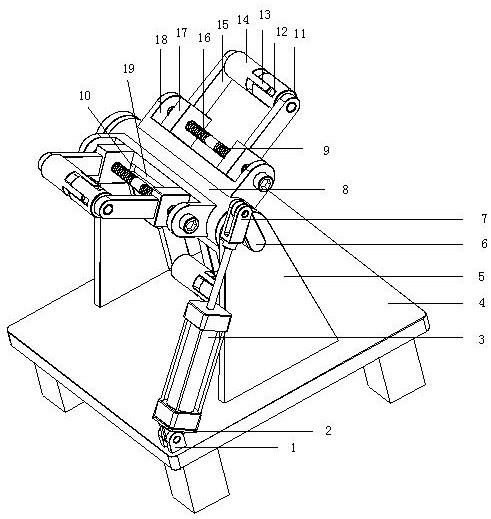

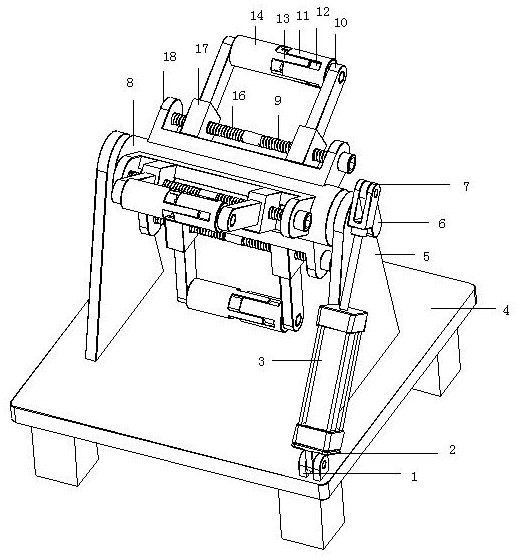

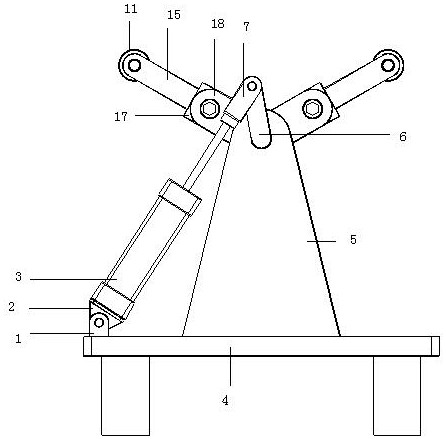

[0024] Such as Figure 1-4 As shown, a regular winding device for a fire-fighting water pipe includes a base 4, and a vertical board 5 is vertically provided at opposite ends of the base 4, and two vertical boards 5 are connected horizontally to rotate. A rotating shaft, on which a mounting part 8 is set, and a plurality of winding roller assemblies for winding fire-fighting water pipes are arranged in an array on the peripheral surface of the mounting part 8, and the winding roller assemblies include two correspondingly fixed on The mounting arm 15 on the mounting part 8, the two mounting arms 15 are respectively connected with a rotating roller through the mounting pivot, and the rotating rollers on the two mounting arms 15 are respectively defined as the first rotating roller 11 and the second rotating roller. Rotating roller 14, the first rotating roller 11 and the second rotating roller 14 are coaxial and both are used to wind the fire hose together, and the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com