Fully-closed kitchen waste transfer platform

A kitchen waste, fully airtight technology, used in trash cans, garbage collection, household appliances, etc., can solve the problems of low waste transfer efficiency on the transfer platform, untimely collection and transportation of kitchen waste, easy to cause dumping, etc. The effect of feeding time, fast charging speed and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments, but the present invention is not limited thereto. It should be noted that, under the premise of not conflicting, the various embodiments described below or between the technical features can be combined arbitrarily to form new the embodiment. The operation methods involved in the following examples are conventional methods unless otherwise specified; the materials and equipment used can be obtained by purchasing unless otherwise specified.

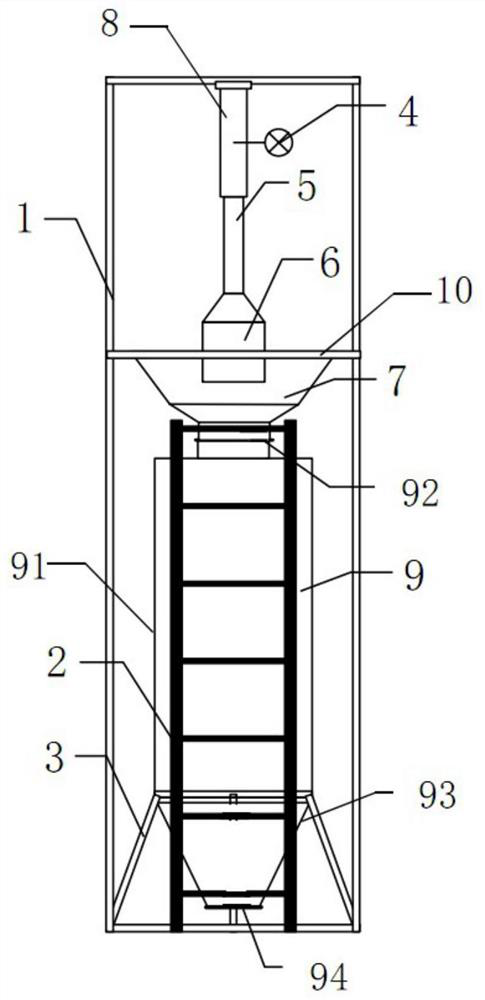

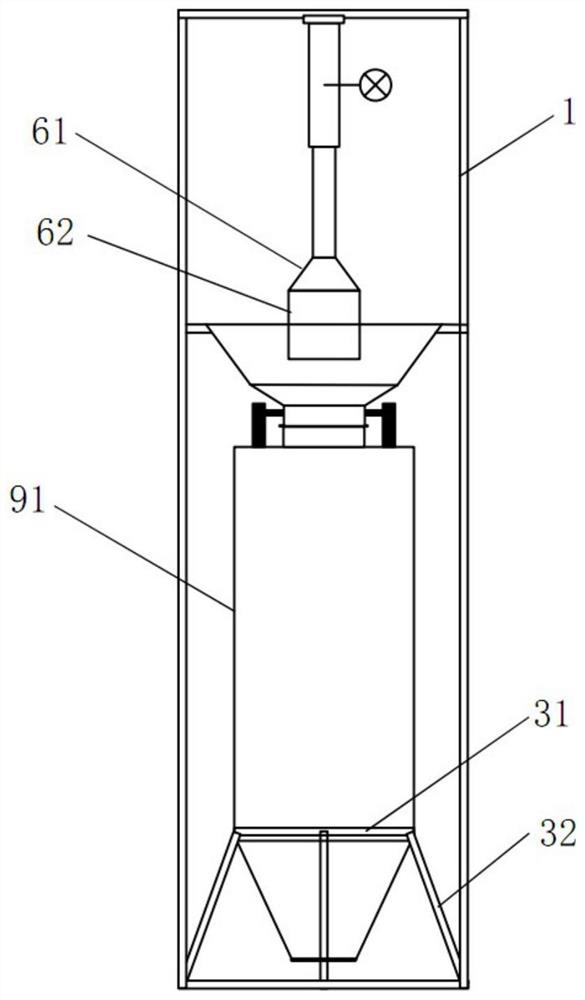

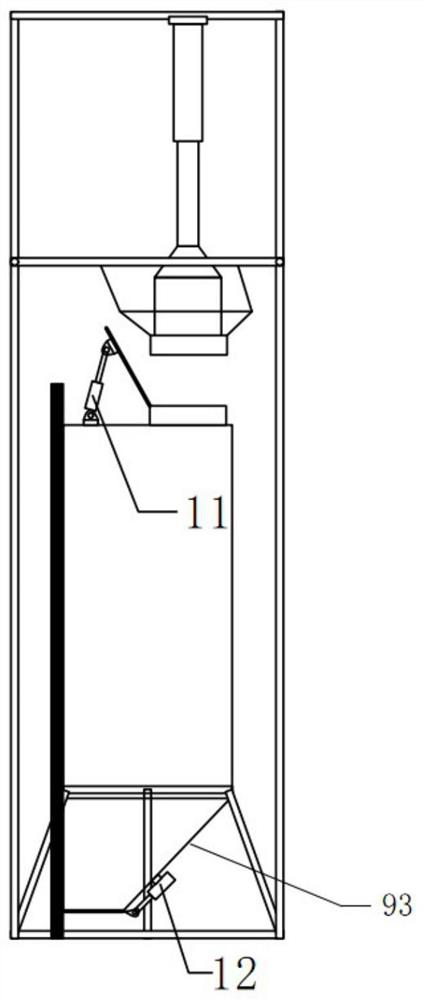

[0026] Figure 1 to Figure 3 They are the front view, rear view and side view of the transfer platform of the present invention respectively. Such as Figure 1 to Figure 3 As shown, the food waste transfer platform provided by the present invention includes a platform support 1 and a compacting mechanism and a feeding chute 7 connected to the top of the platform support 1. The platform support 1 is an integral support of the platform, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com