A stainless steel tableware grinding device

A technology for stainless steel and tableware, which is applied in the direction of grinding machines, manufacturing tools, surface polishing machine tools, etc. It can solve the problems of reduced work efficiency, inability to grind, missing edges and corners, etc., to improve work efficiency, easy and fast installation, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

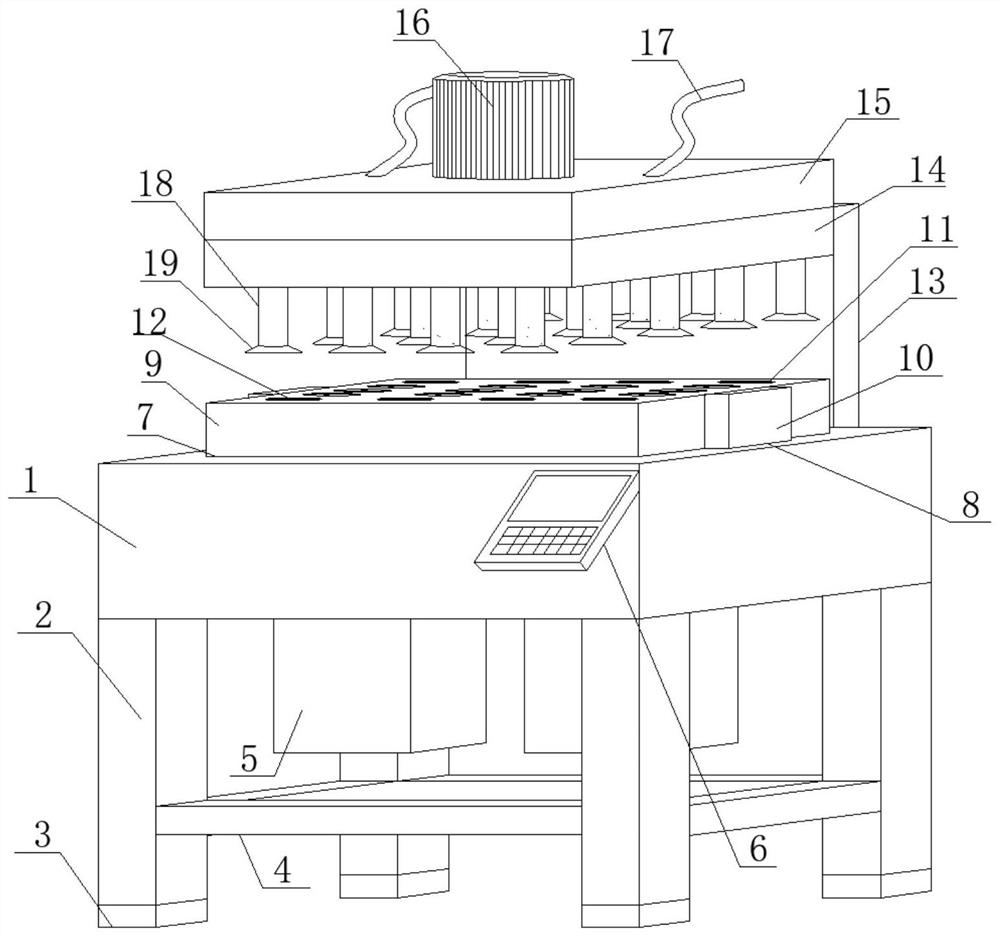

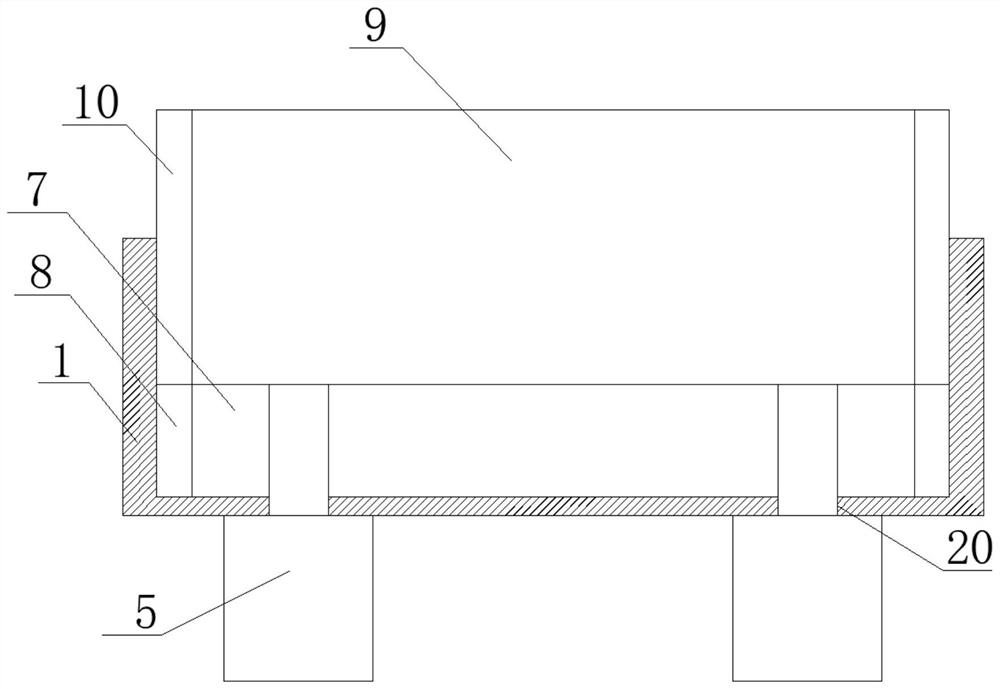

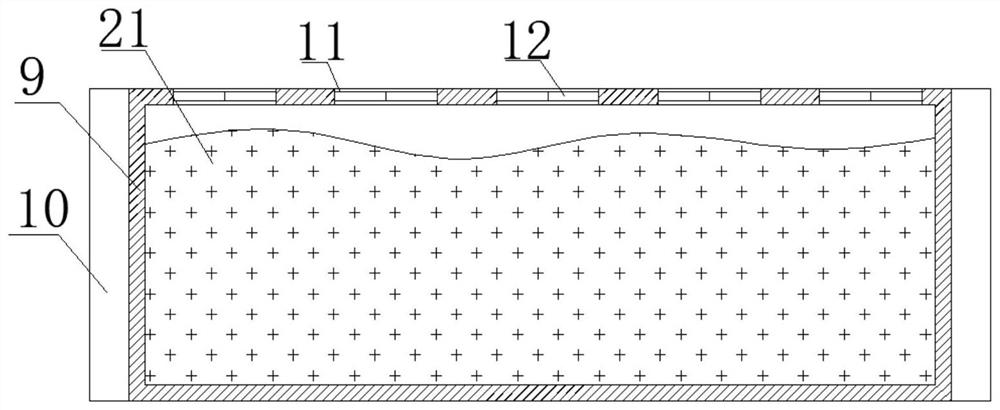

[0027] see Figure 1-3 , in an embodiment of the present invention, a stainless steel tableware grinding device includes a fixed box body 1, the bottom surface of the fixed box body 1 is welded vertically downward with a support pole 2, and the bottom end of the support pole 2 is fixedly clamped with primer Pad block 3, the side of supporting vertical rod 2 is welded with fixed cross bar 4 horizontally, the number of supporting vertical rod 2 is four, and four supporting vertical rods 2 are arranged in parallel with each other, four supporting vertical rods 2 respectively It is fixedly arranged on the bottom surface of the fixed box 1 close to the four corners. The number of bottom rubber pads 3 is consistent with the number of support poles 2 and is set in one-to-one correspondence. The bottom rubber pads 3 are made of soft rubber materials. The fixed horizontal bar 4 is fixed in the shape of a mouth and is fixed between the four support poles 2 near the bottom end. The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com