Steel backing degreasing device for brake pad production and application method thereof

A brake pad and steel back technology, which is applied in the field of steel back degreasing devices for brake pad production, can solve the problems of troublesome loading and unloading, damage, and low efficiency, so as to improve efficiency, prevent time waste, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

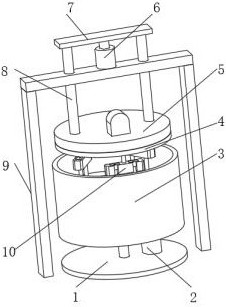

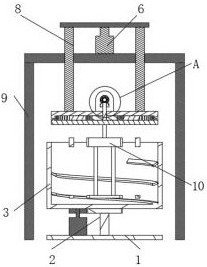

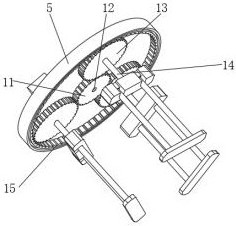

[0042] A steel back degreasing device for brake pad production, such as figure 1 , 2 , 5, 6, and 7, including a base 1 and a gantry 9 fixed on the ground, the top outer wall of the base 1 is connected with an oil removal barrel 3 through the first rotating mechanism 2, and the top outer wall of the gantry 9 is set There is a lifting mechanism, the bottom outer wall of the lifting mechanism is fixedly equipped with a housing 5, the bottom outer wall of the housing 5 is connected with a bottom cover 4 through the form of a T-shaped slider and a chute, and the inner wall of the housing 5 is provided with a second Rotation mechanism, the bottom of the second rotation mechanism is provided with a fixing mechanism 10, the fixing mechanism 10 includes a support block 19 and a limit rod 22, the limit rod 22 is matched with the mounting hole on the steel back, the The support block 19 is fixed on the bottom of the second rotating mechanism, and the inner walls of the support block 19 ...

Embodiment 2

[0048] A kind of using method utilizing the steel back degreasing device in embodiment 1, its concrete steps are as follows:

[0049] S1: Load the steel back, unscrew the removal bolt 24, align the installation hole of the steel back with the limit rod 22 and put it in, when stacked to a certain height, tighten the removal bolt 24;

[0050] S2: Assembling, align the limit rod 22 with the drawing groove 21, and put the first block 23 higher than the height of the support block 19, then move the limit rod 22 downwards, so that the first block 23 is stuck in the Inside a card slot 20;

[0051] S3: start the hydraulic cylinder 6, put the steel back into the degreasing barrel 3, and put the degreasing agent into the degreasing barrel 3;

[0052] S4: start the first motor 17 and the second motor 31, and degrease the steel back;

[0053] S5: prepare for loading, during the degreasing process, take another fixing mechanism 10, and load the steel back according to the steps of S1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com