Chili sauce pickling device

A technology of chili sauce and rotating shaft, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of long accumulation time of chili sauce, difficulty in ensuring the taste and quality of chili sauce, and difficulty in ensuring the deliciousness of chili sauce, so as to reduce post-work Quantity, the effect of ensuring the quality of pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

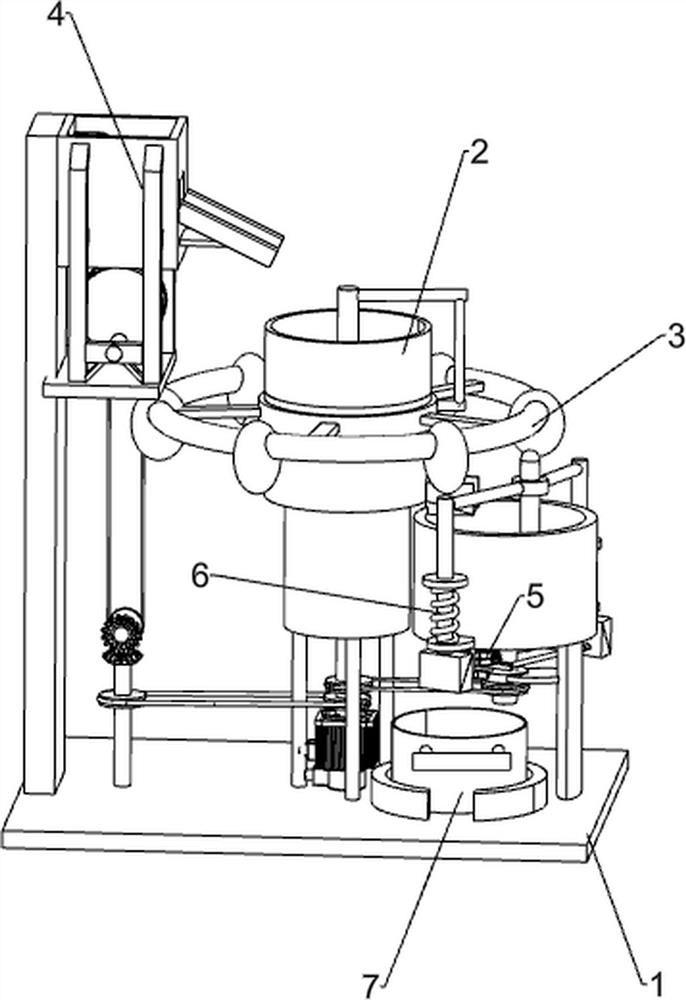

[0056] A chili sauce pickling device, such as Figure 1 to Figure 3 As shown, it includes a base 1 , a cutting mechanism 2 and a mashing mechanism 3 , the top of the base 1 is connected with the cutting mechanism 2 , and the cutting mechanism 2 is connected with the mashing mechanism 3 .

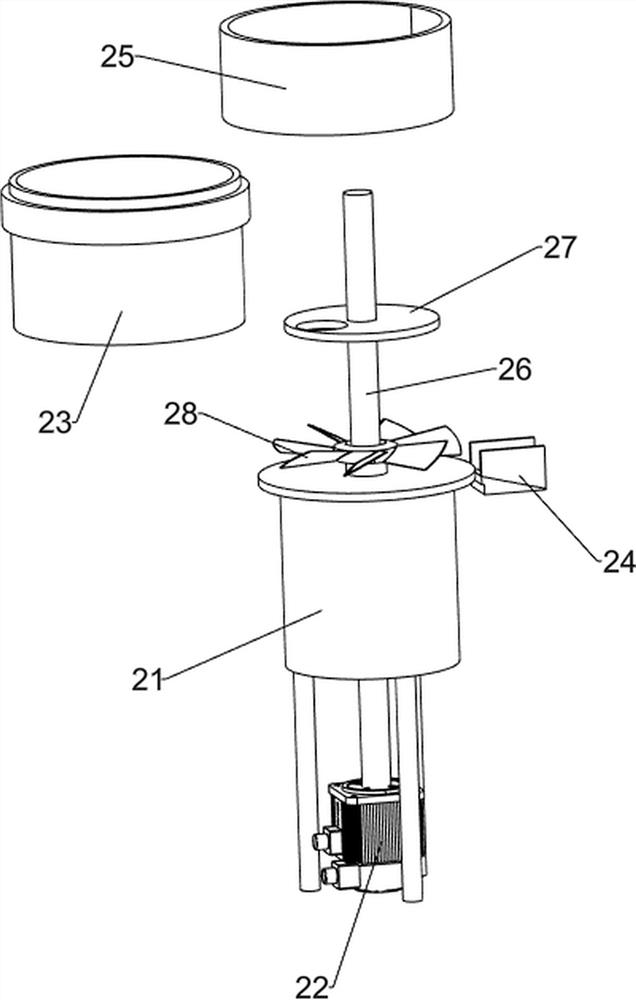

[0057] The cutting mechanism 2 includes a support frame 21, a motor 22, a cutting barrel 23, a discharge chute plate 24, a placement barrel 25, a first rotating shaft 26, a first blanking plate 27 and a blade 28, and the front side of the top of the base 1 is connected with a support Frame 21, the top of support frame 21 is provided with cutting barrel 23, and the top of cutting barrel 23 is connected with placement barrel 25, and the support frame 21 is connected with first rotating shaft 26 in a rotating manner, and is connected with blade 28 and the first rotating shaft 26. Blanking plate 27, the first blanking plate 27 and the bucket 25 all have slits, the blade 28 is located in the cutt...

Embodiment 2

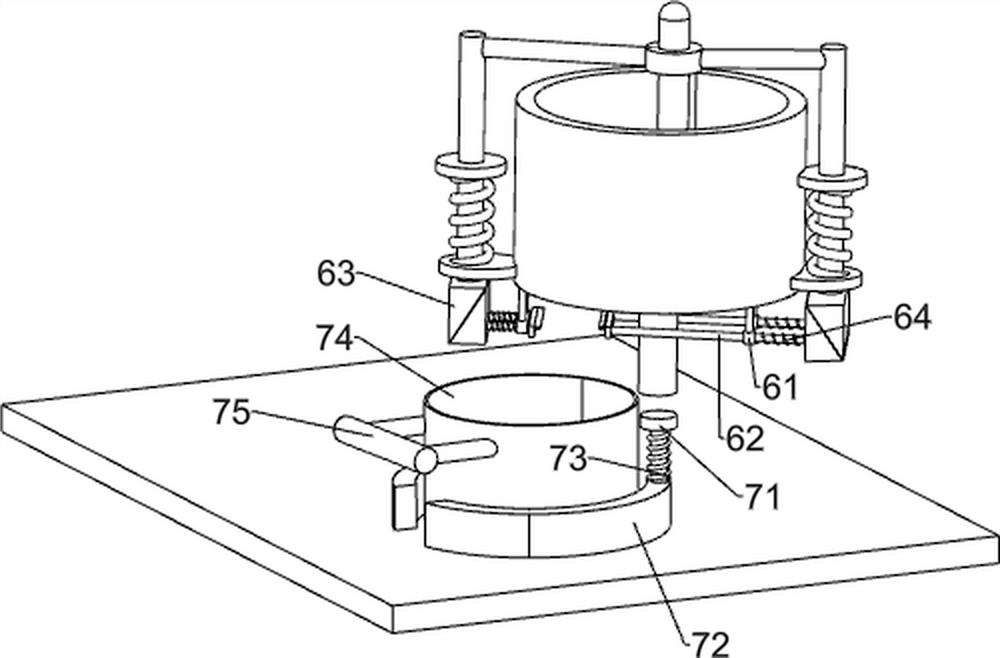

[0061] On the basis of Example 1, such as Figure 4 to Figure 6 As shown, a blanking mechanism 4 is also included, and the blanking mechanism 4 includes a fixed plate 41, a first fixed frame 42, a third rotating shaft 43, a cam 44, a pushing block 45, a chute plate 46, and a first support rod 47 , the second transmission assembly 48, the second support rod 49, the bevel gear set 410 and the third transmission assembly 411, the left side of the top of the base 1 is connected with a fixed plate 41, the upper right side of the fixed plate 41 is connected with the first fixed frame 42, the second The bottom of a fixed mount 42 is rotatably connected with a third rotating shaft 43, the third rotating shaft 43 is connected with a cam 44, and the inner wall of the first fixed mount 42 is slidably connected with a pusher block 45, and the pusher block 45 cooperates with the cam 44 , the upper right side of the first fixed frame 42 is connected with a chute plate 46, the top of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com