Preserved vegetable dehydration device for agricultural product processing

A technology of agricultural product processing and dehydration device, applied in application, food processing, food science and other directions, can solve the problems of lack of turning function of dried prunes, affecting the drying quality of dried prunes, easy contact and covering of dried prunes, etc., so as to improve the drying effect. Drying effect, improved flexibility, improved flipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

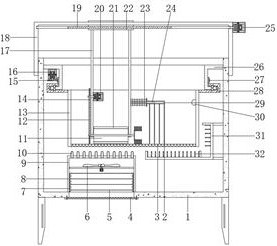

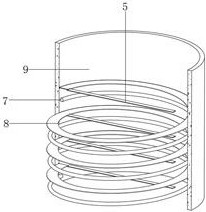

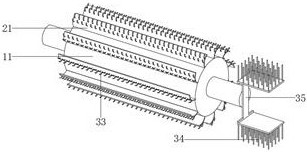

[0030] refer to Figure 1-4 , a kind of dried plum vegetables dehydration device for agricultural product processing, comprising a box body 1 with legs welded at the four corners of the outer wall of the bottom, a fixed ring tube 26 welded on the inner wall of one end of the box body 1 near the top, and the bottom end of the fixed ring tube 26 is rotatably connected by a bearing There is a supporting ring 28, and the inner wall of the bottom circumference of the supporting ring 28 is fixed with a drying cylinder 13 by bolts, the bottom of the drying cylinder 13 is fixedly equipped with a net end plate 3, and the side of the bottom of the box body 1 is equipped with an air inlet mechanism, and the top outer wall of the box body 1 is welded with a fixed top frame 18, the top of the fixed top frame 18 is rotatably connected with a threaded rod 19, and the outer wall of one end of the threaded rod 19 is threaded to be slidably connected with the fixed top frame 18 Moving block 22,...

Embodiment 2

[0041] refer to figure 1 and Figure 5 , a dried plum vegetable dehydration device for agricultural product processing. Compared with Embodiment 1, this embodiment also includes that the inner wall of the circumference of the drying cylinder 13 near the end of the sleeve 29 is fixedly equipped with convex balls 30 equidistant and annularly distributed.

[0042] When the present invention is used: through the setting of the convex ball 30, when the sleeve 29 approaches the inner wall of the drying cylinder 13 along with the moving block 22, the fixed frequency contacts the sleeve 29, and cooperates with the vibrating spring 23 to make the vertical lever 2 follow the sleeve. Tube 29 vibrates back and forth to improve the turning effect of dried plums, so as to achieve the purpose of ensuring the quality of dehydration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com