Heat dissipation structure, battery module, heat dissipation system and control method of heat dissipation system

A technology of heat dissipation structure and battery module, applied in the field of heat conduction, can solve the problem of poor heat dissipation effect at the connection row, and achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

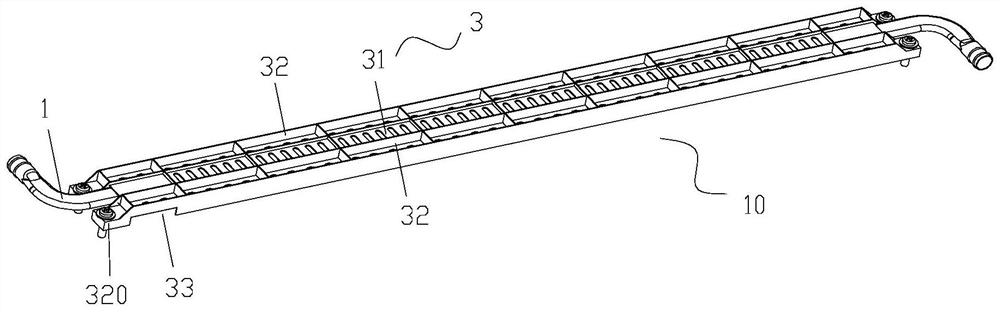

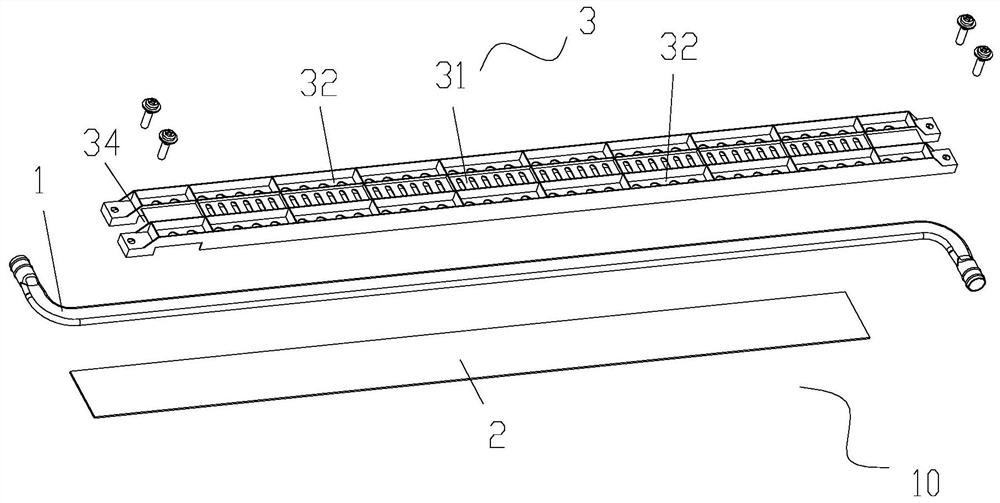

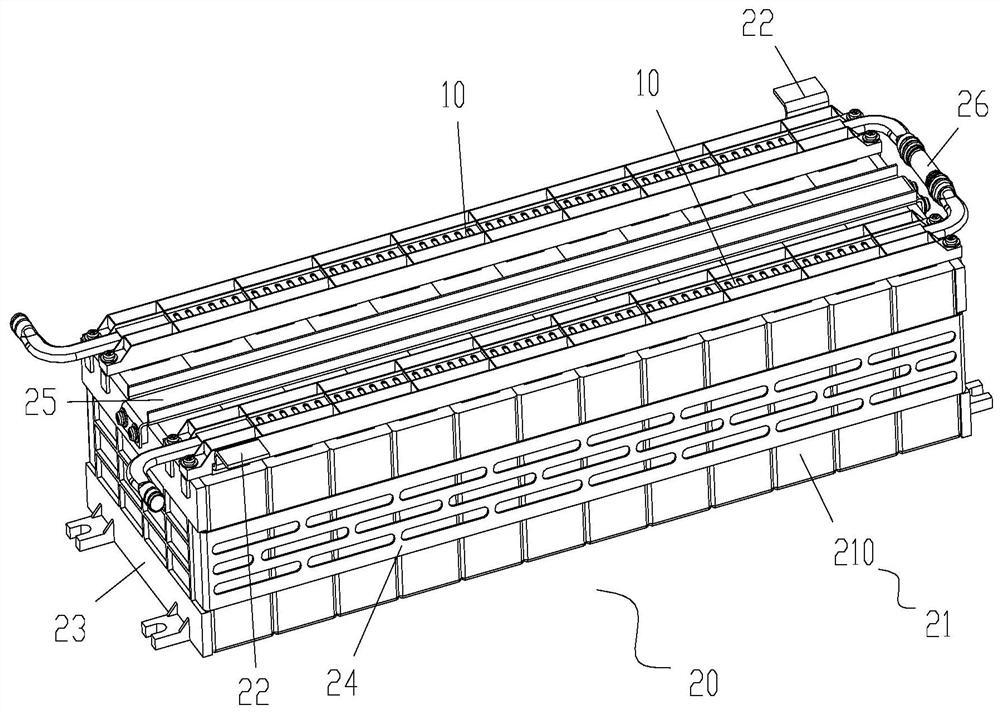

[0040] Such as figure 1 and Figure 7 As shown, the present invention provides a heat dissipation structure, including: a liquid cooling tube 1, the liquid cooling tube 1 is located on the side of the connecting row 22 of the battery module away from the cell assembly 21, and the extending direction of the liquid cooling tube 1 is parallel to the connection The extension direction of the row 22 is used to dissipate heat from the battery module by feeding the flowing cooling liquid into the liquid cooling tube 1; the insulating part 2, the insulating part 2 is strip-shaped, and the extending direction of the insulating part 2 is parallel to the liquid cooling tube 1 In the direction of extensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com