A method and system for real-time detection and processing of lithium battery pole piece defects

A technology of real-time detection and processing methods, applied in optical testing flaws/defects, measuring devices, instruments, etc., can solve problems such as poor consistency, poor detection accuracy, slow response, etc., to improve accuracy, eliminate response time, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

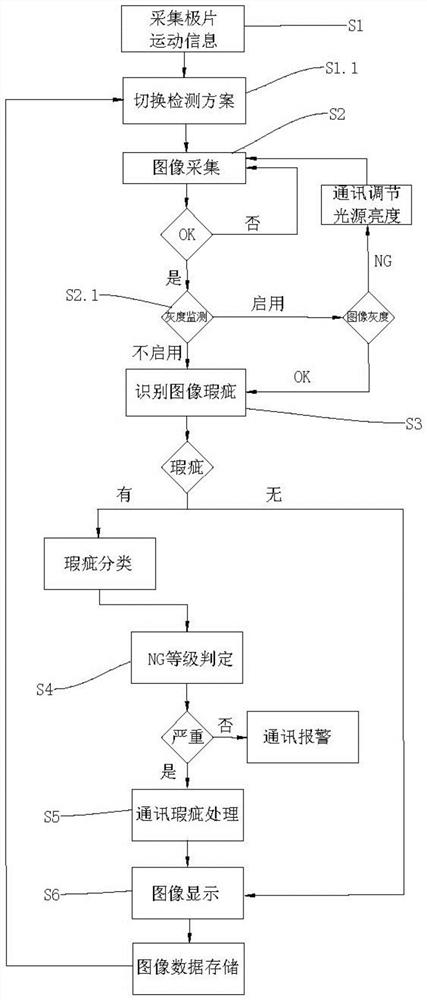

[0039] The invention provides a method for real-time detection and processing of lithium battery pole piece defects, such as figure 1 As shown, including the following steps S1-S6:

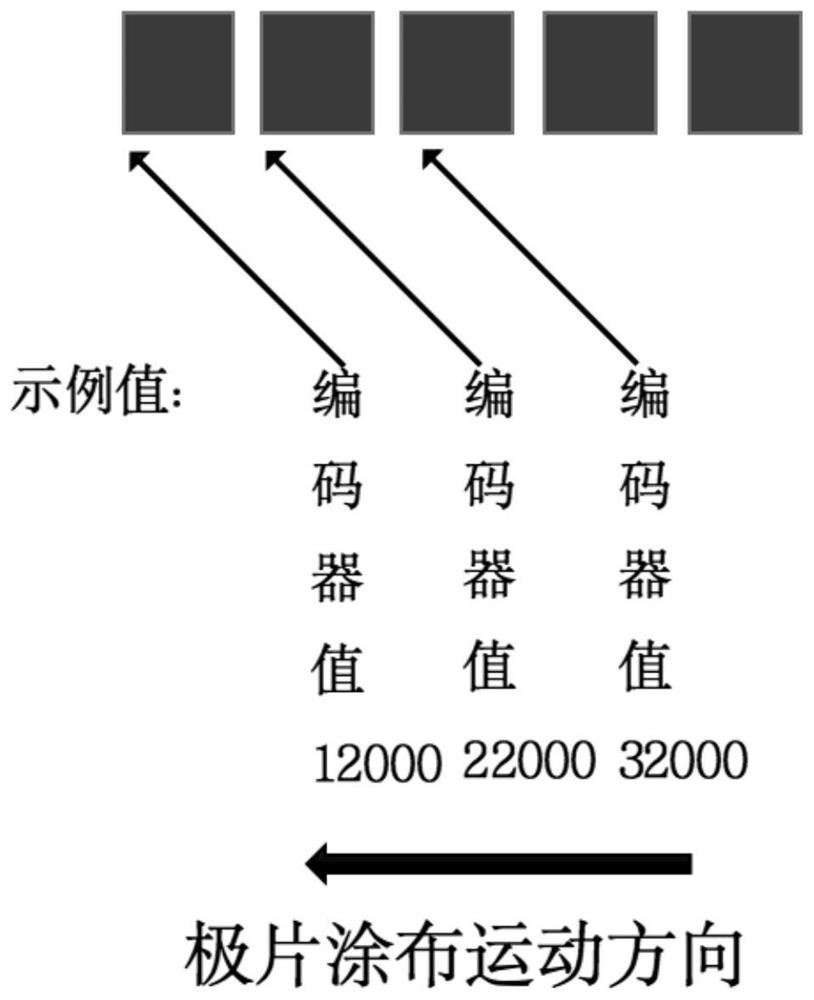

[0040] S1. Collect the movement information of the pole piece: the battery pole piece is bypassed by several rollers to drive the pole piece to carry out the tension transportation operation. At the same time, the encoder is connected with the roller transmission. V are converted into electronic signals.

[0041] Specifically, in step S1, the continuous defect detection operation is performed on the battery pole piece at the position of the roller, which can prevent the machine shake from affecting the image acquisition of the pole piece by the camera, ensure that the defect position information of the pole piece can be accurately collected, and ensure Reliability of the defect detection process.

[0042] S1.1. Switch detection scheme: select a suitable pole piece detection scheme from multiple po...

Embodiment 2

[0060] Such as Figure 6 As shown, the present invention provides a real-time detection and processing system for lithium battery pole piece defects, including:

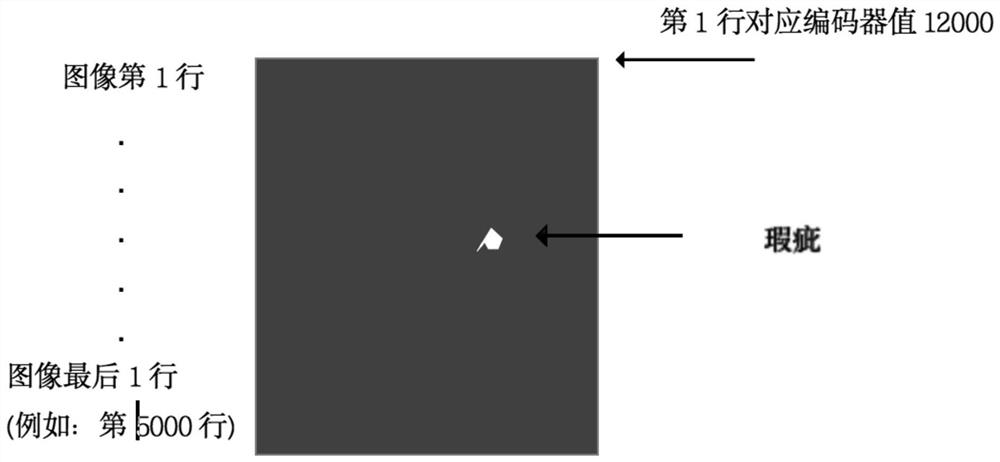

[0061] Pole piece motion information collection module: the pole piece motion information collection module converts the pole piece motion information into electronic signals, and records the encoder value C1 of the image line signal at the same time;

[0062] Vision system: the vision system is triggered by the pole piece motion information acquisition module, and the vision system collects the position information of the image defect and calculates it with the encoder value C1 to convert it into the encoder value C2;

[0063]Controller: the controller receives the pole piece movement information of the pole piece movement information acquisition module and the coded value C2 of the vision system, and sends a flaw processing time signal to the flaw processing device; preferably, the controller is PLC controller;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com