Automobile sensor production device

A production equipment and sensor technology, applied in the field of automotive sensor production equipment, can solve the problems of reduced production efficiency, long drying time, lack of shock absorption function, etc., and achieve the effect of improving practicability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

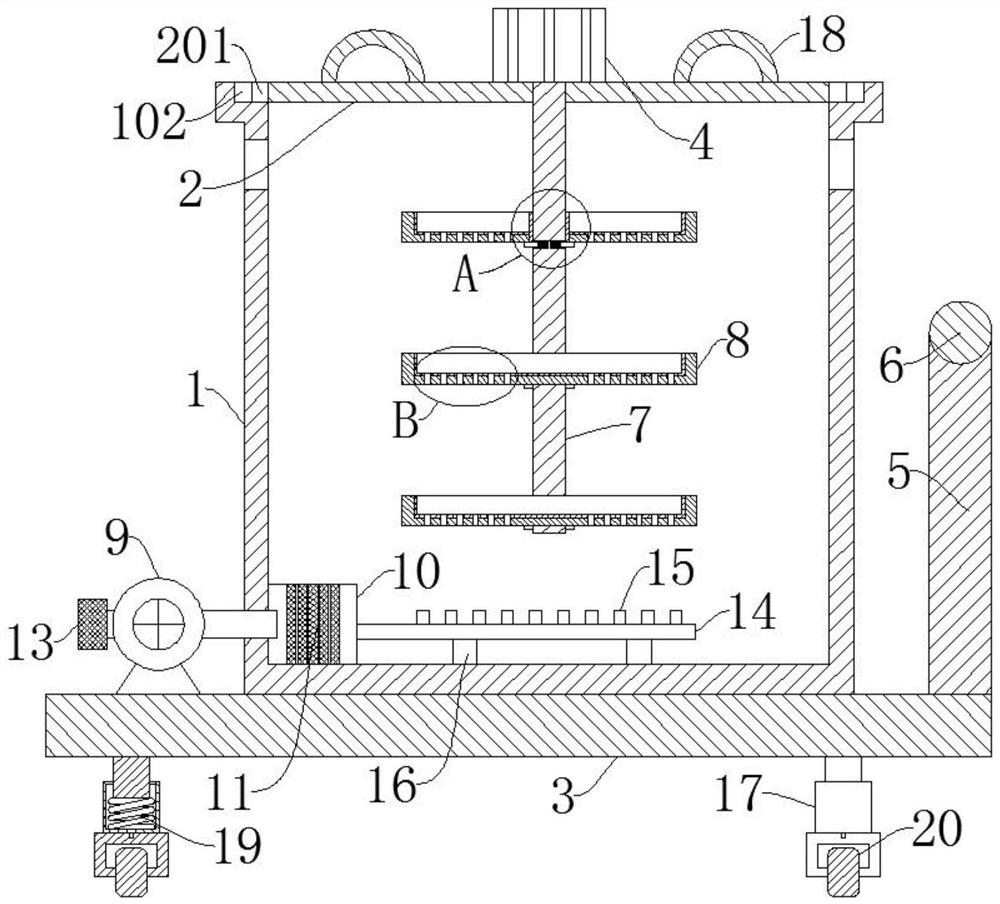

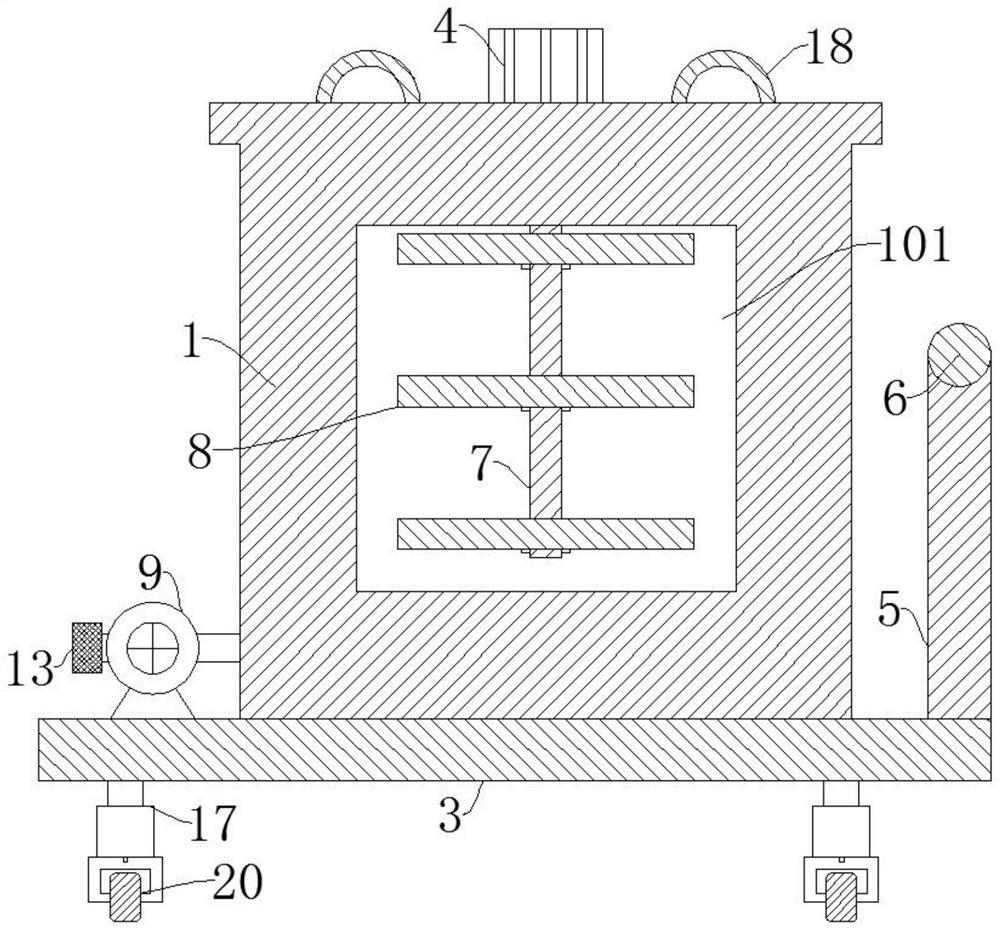

[0028]ReferenceFigure 1-5, Automotive sensor production equipment, including a box body 1, the upper end of the box body 1 is connected with a box cover 2, the box cover 2 is fixedly connected with a first motor 4, the output end of the first motor 4 is fixedly connected with a rotating rod 7, the rotating rod 7 penetrates through the box cover 2, a plurality of placing plates 8 are connected to the rotating rod 7 by screwing, and the placing plate 8 is provided with a placing groove, the bottom of the placing groove is provided with a ventilation hole 801, and the inner bottom side of the box body 1 is fixedly connected with A drying box 10, a heating plate 11 is fixedly connected to the drying box 10, a ventilation pipe 14 is fixedly connected to one side of the drying box 10, and a plurality of nozzles 15 are arranged on the ventilation pipe 14 and matched with the position of the placing plate 8. The lower end of the box body 1 is fixedly connected with a base 3, and the upper e...

Embodiment 2

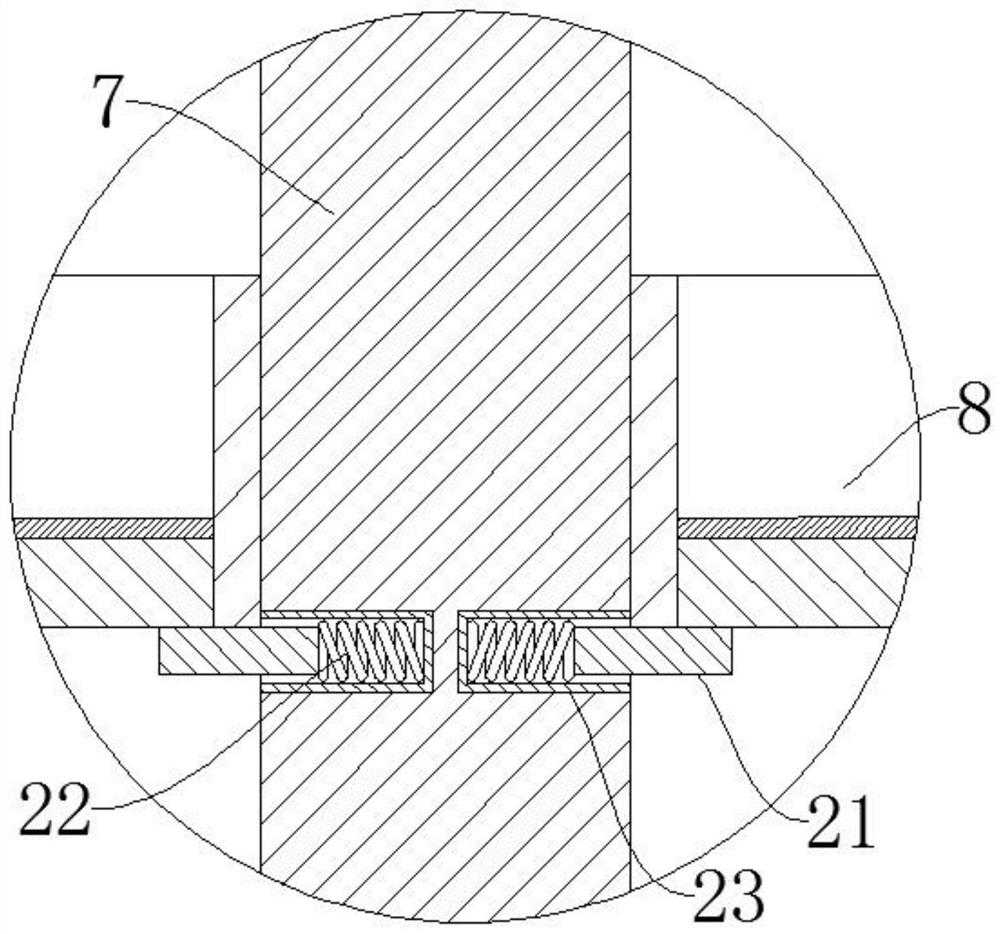

[0031]ReferenceFigure 1-5The automobile sensor production equipment is basically the same as that of the first embodiment. Furthermore, the rotating rod 7 is provided with two symmetrical grooves 23. The grooves 23 are fixedly connected with a return spring 22, and the return spring 22 is far away One end of the bottom of the groove 23 is fixedly connected to the limit rod 21, which effectively prevents the placement plate 8 from moving downwards when rotating, and then falls off the rotating rod 7, which acts as a limiter and improves the stability of the device .

Embodiment 3

[0033]ReferenceFigure 1-5, The production equipment for automotive sensors is basically the same as that of the first embodiment. Furthermore, the two ends of the box cover 2 are fixedly connected with first magnetic blocks 201, and both sides of the upper end of the box body 1 are provided with matching first magnetic blocks 201. The second magnetic block 102 can prevent the cover 2 from shaking during operation, which further improves the stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com