Vacuum low temperature drying oven for the preparation of powder essence

A technology of vacuum low-temperature drying, powder essence, applied in drying chamber/container, drying solid materials, non-progressive dryer, etc., can solve the problems of reduced sublimation rate, low rate of internal water vapor extraction, affecting drying rate, etc. Achieve the effect of improving decomposition speed, high degree of automation, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

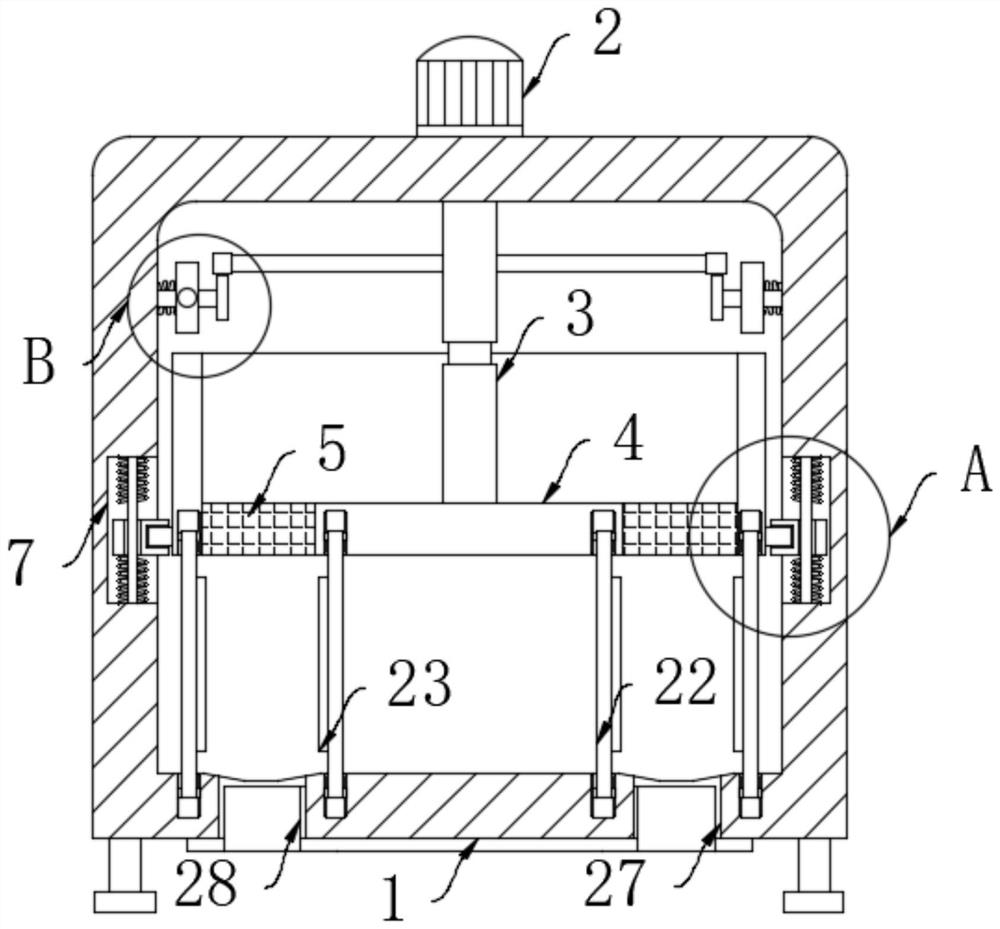

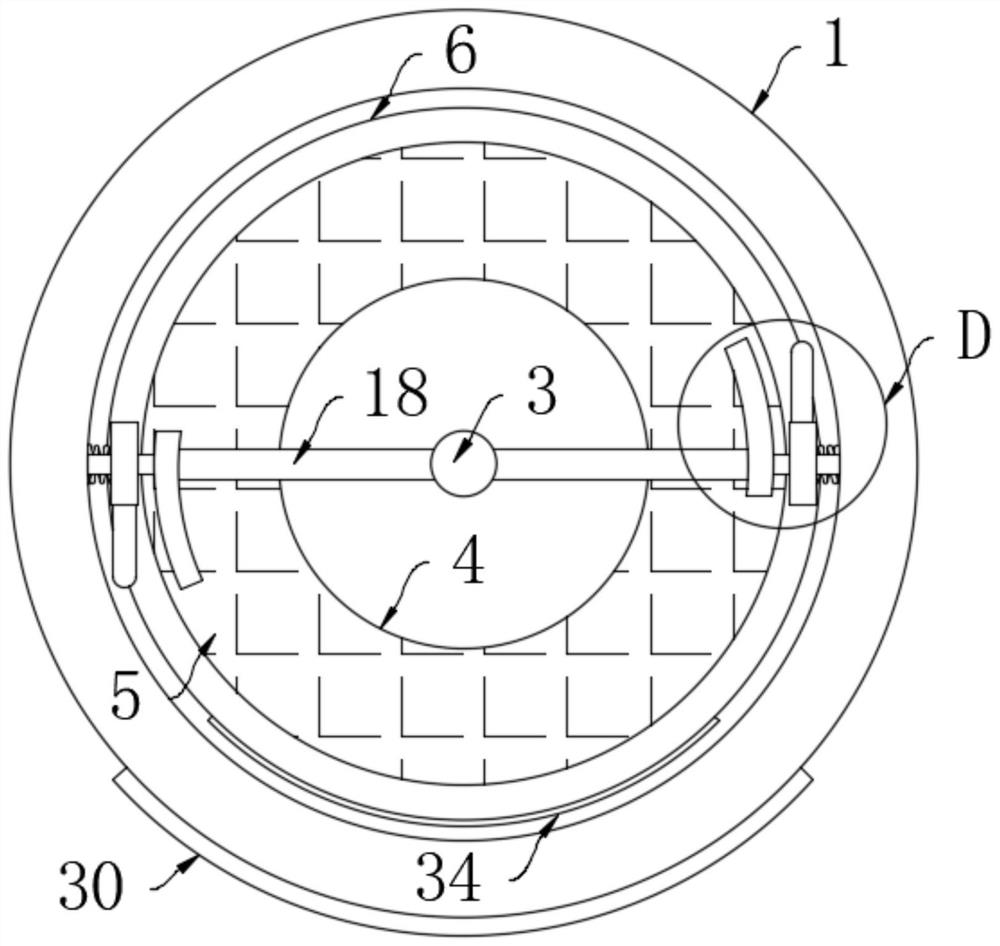

[0035] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments. Based on embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative work, are within the scope of protection of the present invention.

[0036] In the description of the present invention, it is to be understood that the term "up", "down", "front", "back", "left", "right", "top", "bottom", "inside", "outside" and the like indicates the orientation or position relationship based on the accompanying drawings, only to facilitate the description of the present invention and simplify the description, and not to indicate or imply that the means or elements referred to must ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com