Hydropower station surge chamber non-welding sealing tool and installation method thereof

An installation method and surge chamber technology, which is applied in the non-welded sealing tooling and installation field of the surge chamber of a hydropower station, can solve problems that affect the safe and stable operation of the unit, damage the steel plate on the inner wall of the gas chamber, and reduce the strength of the steel plate, so as to reduce the labor force of employees. strength, reduce safety risks, and improve sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

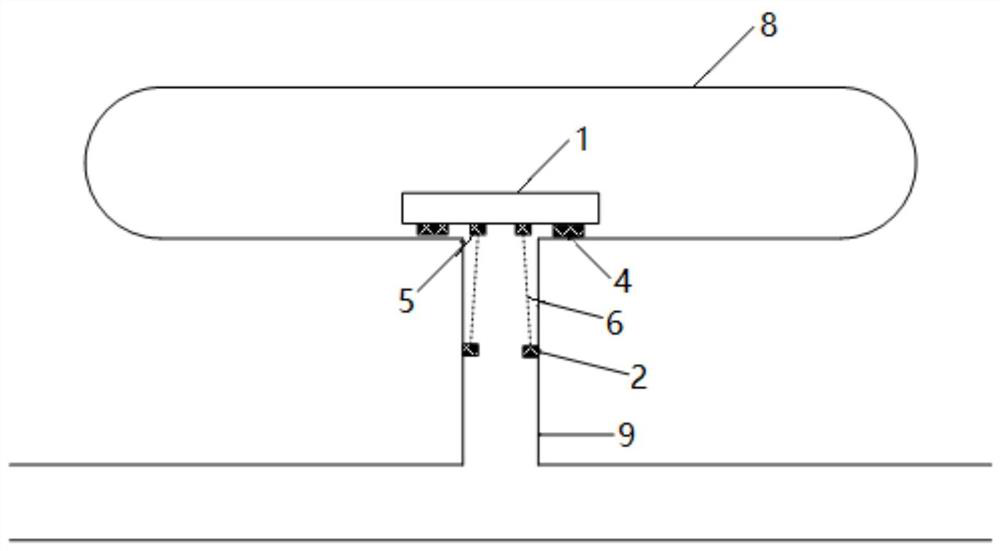

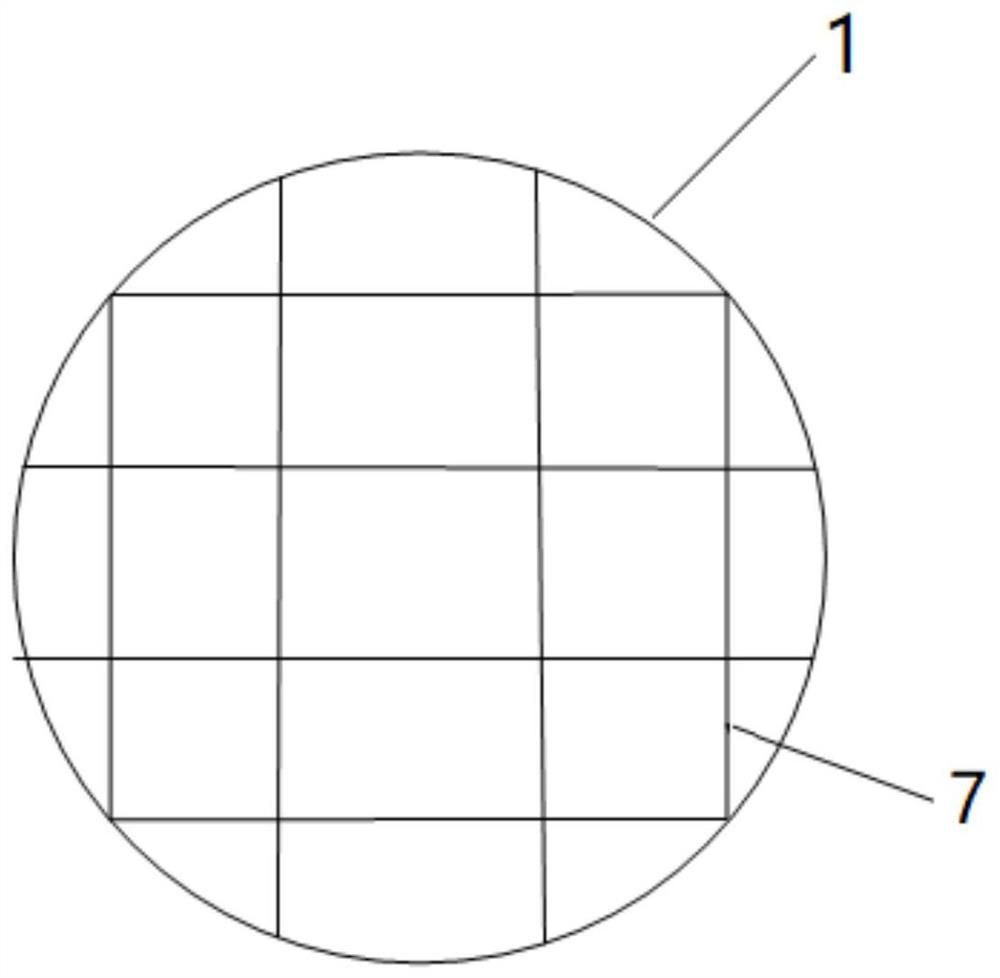

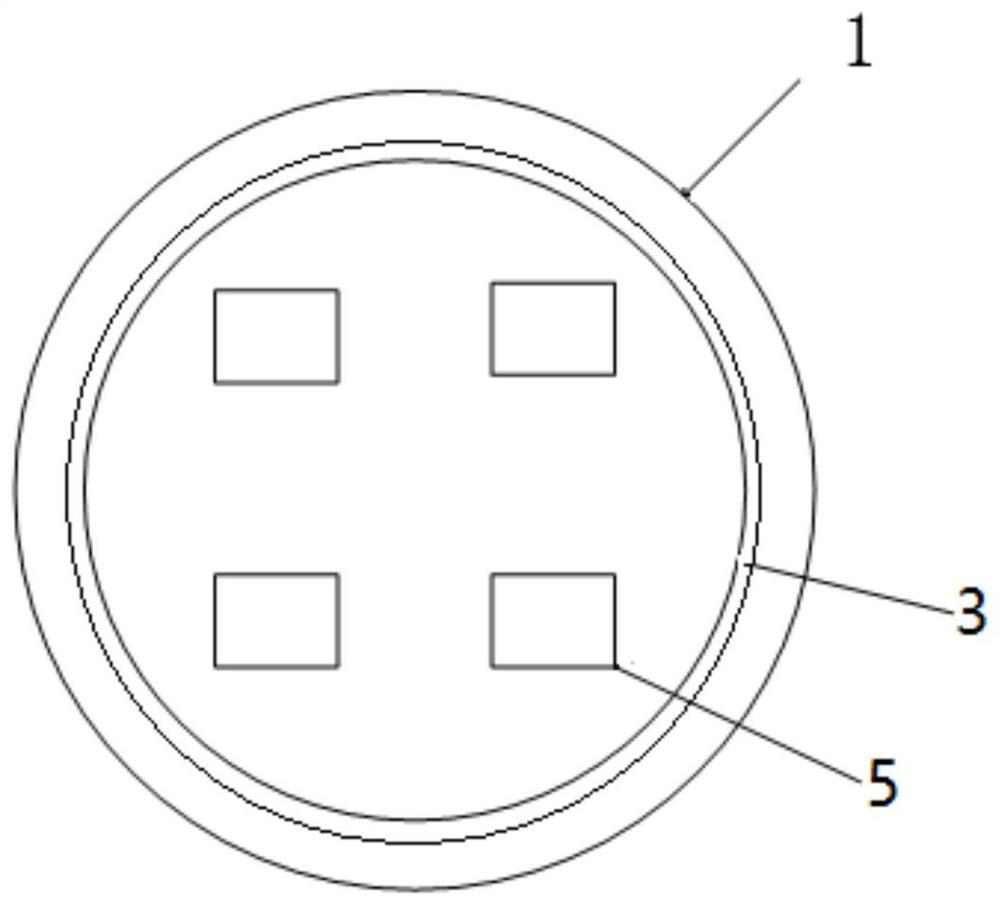

[0036] Such as figure 1 , is the non-welded sealing tooling of the surge chamber of a hydropower station of the present invention, including a sealing blocking plate 1 and a plurality of first tensioning lugs 2; the lower surface of the sealing blocking plate 1 is provided with an annular groove 3, and the annular groove 3 is provided with The sealing and water-stopping device 4; the lower surface of the sealing blocking plate 1 is fixedly connected with a plurality of second tensioning lugs 5, the first tensioning lug 2 and the second tensioning lug 5 are connected with a cable device 6, and the cable device 6. A chain hoist can be used; when in use, the sealing and water-stopping device 4 is in close contact with the mouth of the intermediate connecting pipe 9 in the pressure regulating chamber 8 in the circumferential direction, and several first tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com