Tunneling hydraulic cylinder

A hydraulic cylinder and main body technology, applied in the field of hydraulic cylinders, can solve the problems of increasing the load of the excavation hydraulic cylinder, wear of the piston rod, affecting the sealing of the excavation hydraulic cylinder, etc., and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

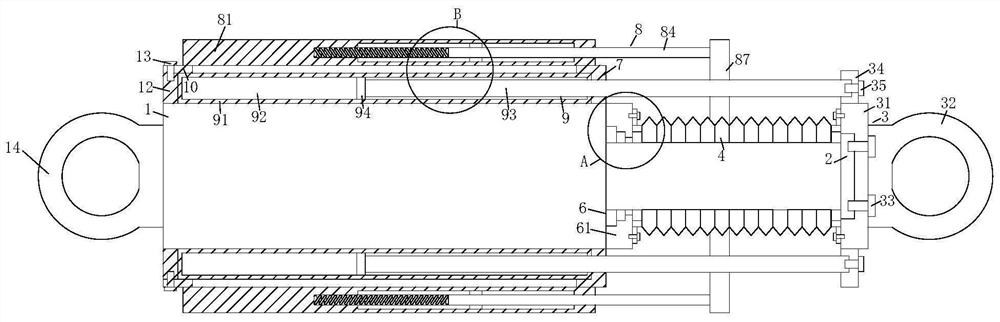

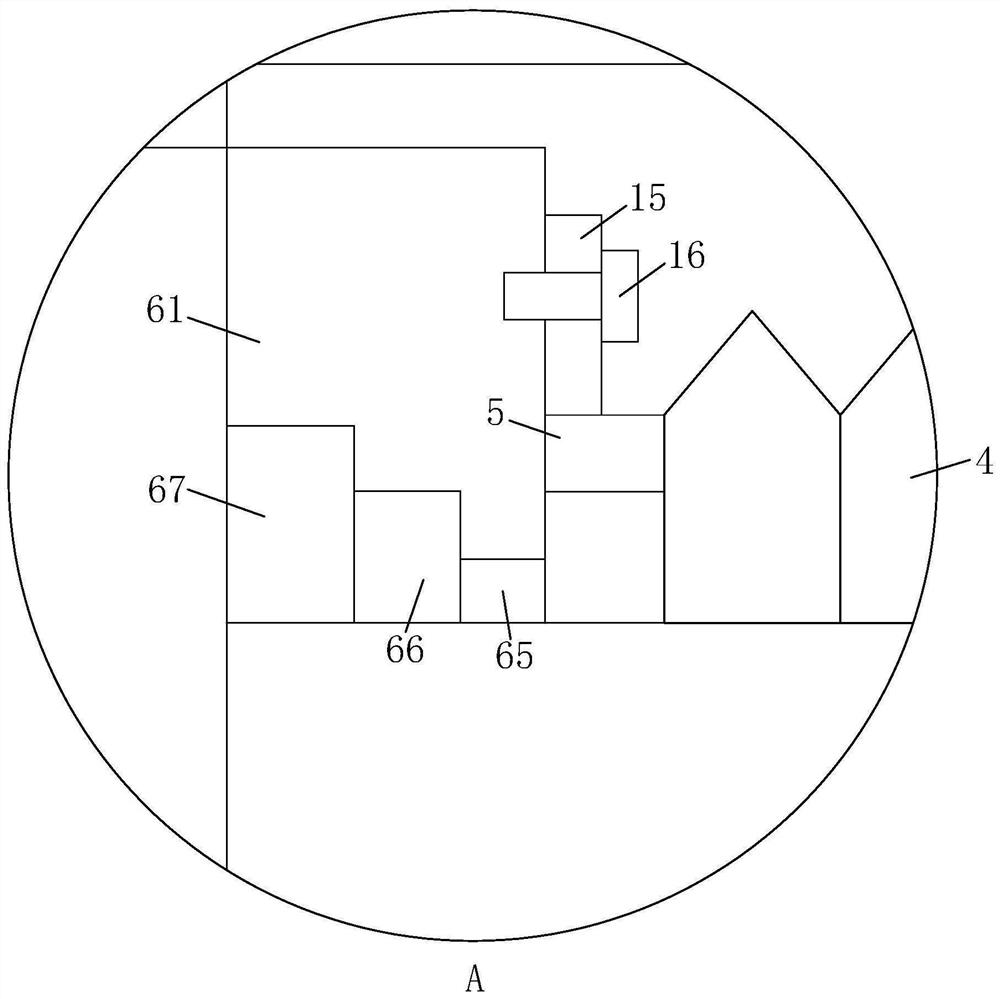

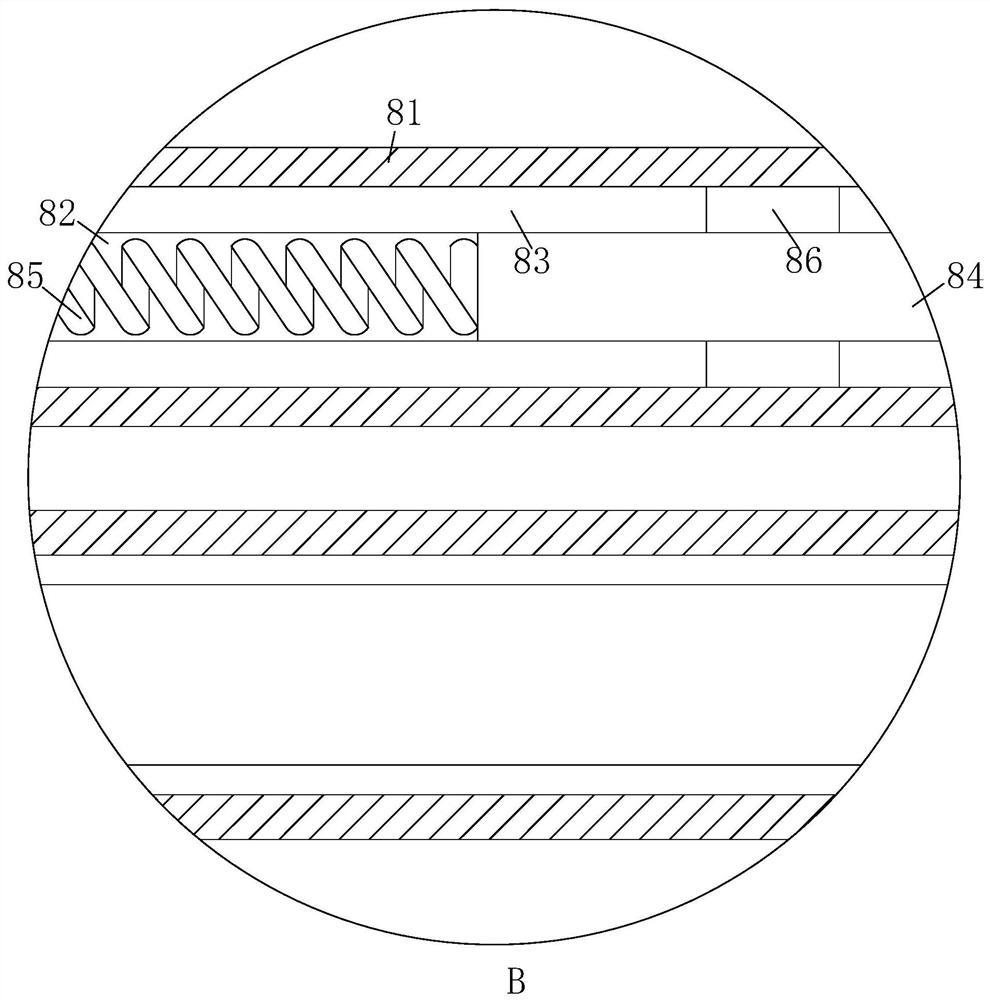

[0027] like Figure 1-Figure 7As shown, an excavation hydraulic cylinder according to the present invention includes a hydraulic cylinder main body 1, the piston rod of the hydraulic cylinder main body 1 is located on one side of the hydraulic cylinder main body 1 and the moving end of the piston rod is fixedly connected with a mounting plate 2, A connecting head 3 is installed on the mounting plate 2, and a dust-proof pipe 4 is set on the outside of the piston rod of the hydraulic cylinder main body 1. Both ends of the dust-proof pipe 4 are fixedly connected with a connecting ring 5, and the connecting ring 5 is sleeved and fixedly connected with a second fixed ring 15 on the outer wall of the circumference of 5, and the fourth bolt 16 is threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com