Environment-friendly power generation method utilizing livestock and poultry excrement to produce biogas

A technology of livestock and poultry manure and biogas, which is applied in the direction of gaseous engine fuel, chemical instruments and methods, engine components, etc., and can solve problems such as unsatisfactory livestock and poultry manure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

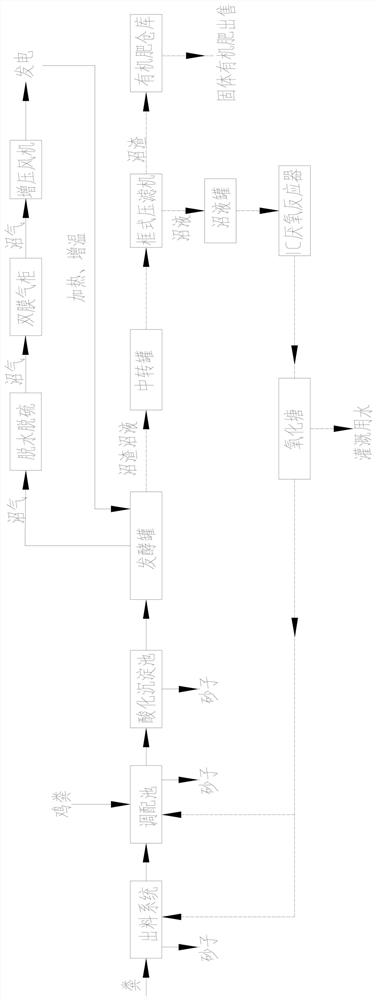

[0015] see figure 1 , a kind of electricity generation method utilizing livestock and poultry manure to produce biogas environment-friendly electricity generation of the present invention, comprises the following steps:

[0016] (1) Pre-screen the livestock and poultry manure through the discharge system to remove impurities such as sand;

[0017] (2) Put the livestock and poultry manure screened out of sand into the blending tank for blending, add auxiliary materials for blending, and further screen out sand and other impurities;

[0018] (3) Put the prepared livestock and poultry manure into the acidification sedimentation tank for precipitation and acidification, and further screen out impurities such as sand;

[0019] (4) Feed the acidified and precipitated materials into the fermentation tank to produce biogas. After dehydration and desulfurization, the generated biogas enters the double-membrane gas tank to remove impurities, and then sends it to the power generation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com