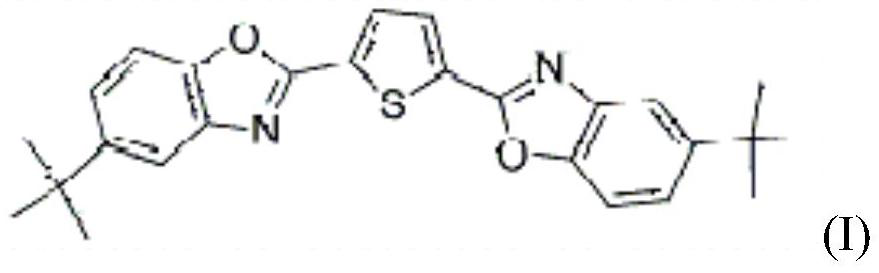

Plastic brightening agent OB and preparation method thereof

A whitening agent and plastic technology, applied in organic chemistry and other directions, can solve the problems that the reaction is difficult to reach the end point, the material is easy to become very thick, and the reaction is not easy to complete, and the reaction is uniform and sufficient, not easy to aggregate, and the reaction is fast and complete. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

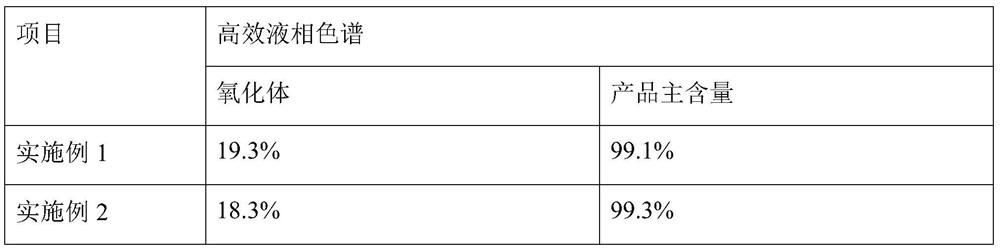

Embodiment 1

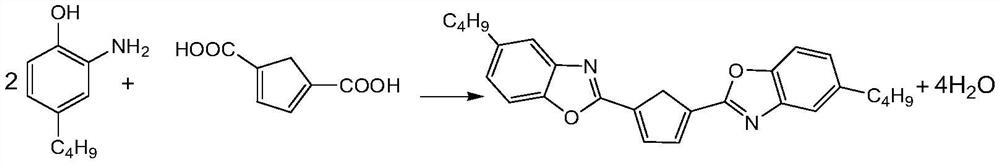

[0023] A kind of plastic brightener OB, described plastic brightener OB is made by plastic brightener OB crude product, N-methylpyrrolidone and methanol; Wherein, described plastic brightener OB crude product is made of thiophene di 25 parts of carboxylic acid, 46 parts of o-amino p-tert-butylphenol, 124 parts of condensation solvent, 2.5 parts of boric acid, 0.6 part of catalyst and 108 parts of dimethylformamide; The whitening agent OB crude product is in the ratio of 1.5:1 by weight; the ratio of the methanol and the plastic whitening agent OB crude product is 4:1 by weight. The condensation solvent is composed of diphenyl ether and toluene, and the ratio of the diphenyl ether to the toluene is 1.5:1 in parts by weight.

[0024] A kind of preparation method of plastic brightener OB, concrete steps are as follows:

[0025] (1) condensation

[0026] Add 2,5-thiophene dicarboxylic acid and o-amino-p-tert-butylphenol into the condensation tank, the stirring speed is 50r / min, ...

Embodiment 2

[0031] A kind of plastic brightener OB, described plastic brightener OB is made by plastic brightener OB crude product, N-methylpyrrolidone and methanol; Wherein, described plastic brightener OB crude product is made of thiophene di 24 parts of carboxylic acid, 47 parts of o-amino p-tert-butylphenol, 123 parts of condensation solvent, 3 parts of boric acid, 0.5 part of catalyst and 105-110 parts of dimethylformamide; the N-methylpyrrolidone and the The ratio of the plastic brightener OB crude product is 1:1 by weight; the ratio of the methanol and the plastic brightener OB crude product is 5:1 by weight. The condensation solvent is composed of diphenyl ether and toluene, and the ratio of the diphenyl ether to the toluene is 1:1 in parts by weight.

[0032] A kind of preparation method of plastic brightener OB, concrete steps are as follows:

[0033] (1) condensation

[0034] Add 2,5-thiophene dicarboxylic acid and o-amino-p-tert-butylphenol into the condensation tank, stirri...

Embodiment 3

[0039] A kind of plastic brightener OB, described plastic brightener OB is made by plastic brightener OB crude product, N-methylpyrrolidone and methanol; Wherein, described plastic brightener OB crude product is made of thiophene di 26 parts of carboxylic acid, 45 parts of o-amino p-tert-butylphenol, 125 parts of condensation solvent, 2 parts of boric acid, 0.7 part of catalyst and 105 parts of dimethylformamide; The crude product of whitening agent OB is in the ratio of 2:1 by weight; the ratio of methanol and the crude product of plastic brightener OB is 3:1 by weight. The condensation solvent is composed of diphenyl ether and toluene, and the ratio of the diphenyl ether to the toluene is 2:1 in parts by weight.

[0040] A kind of preparation method of plastic brightener OB, concrete steps are as follows:

[0041] (1) condensation

[0042]Add 2,5-thiophene dicarboxylic acid and o-amino-p-tert-butylphenol into the condensation tank, the stirring speed is 60r / min, the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com